Open width sand washing machine

A sand washing machine, open-width technology, applied in textile and paper making, roughening, fabric surface trimming and other directions, can solve the problems of non-compliance with environmental protection requirements, high resource and energy consumption, fabric damage, etc. Low consumption of washing aids, low consumption of resources and energy, and the effect of meeting environmental protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

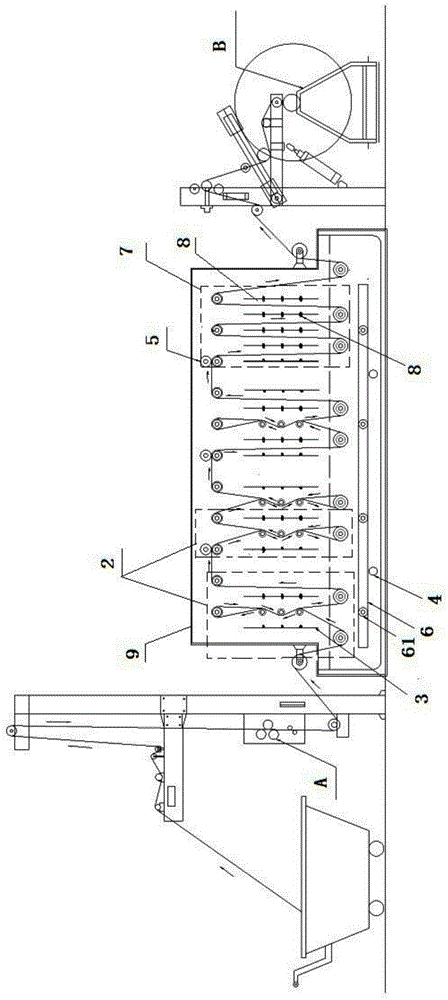

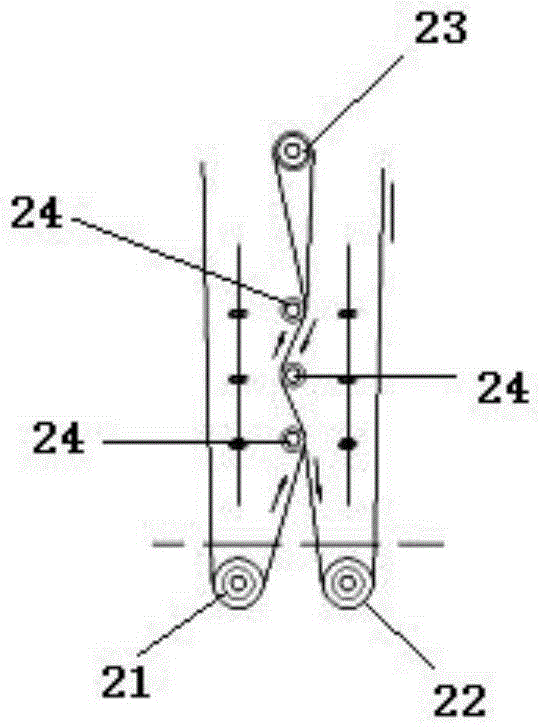

[0034] see figure 1 , 2 , the invention discloses a flat-width sand washing machine. Such as figure 1 As shown: it includes a sand washing aid container 1, and the top of the sand washing aid container 1 is provided with several rows of conveying roller groups 2 with friction rollers ( figure 1 The embodiment in is vertically continuously arranged in four rows with the conveying roller group 2) with the friction roller, and this conveying roller group 2 with the friction roller is provided with a high-pressure nozzle 3 with a spout on one side or both sides, and these high-pressure nozzles The input ends of 3 are all connected with the sand washing auxiliary agent container 1 or the sand washing auxiliary agent storage mechanism through the pump 4. Such as figure 2 As shown, the delivery roller group 2 with friction rollers includes an input roller 21 for the inp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com