Patents

Literature

48results about How to "Improve sand washing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

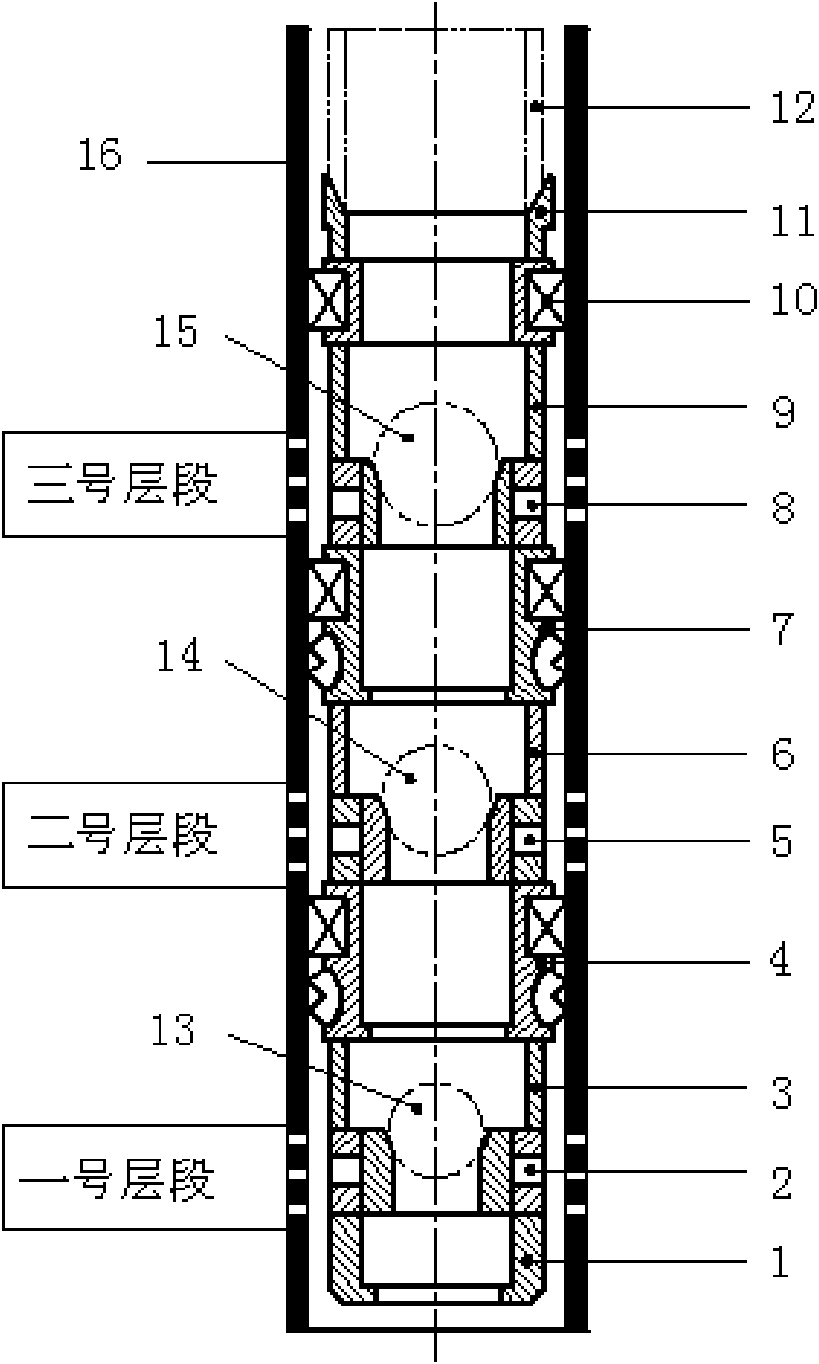

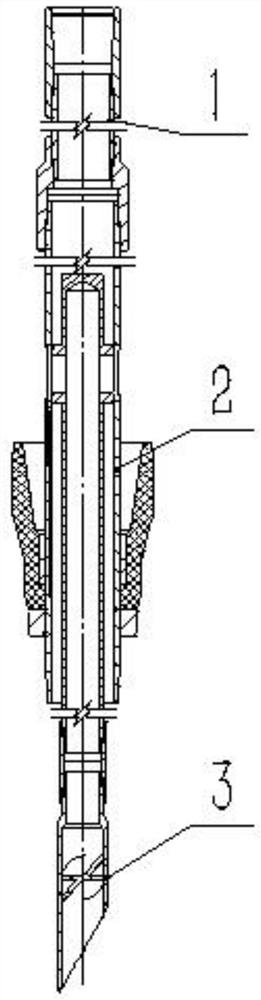

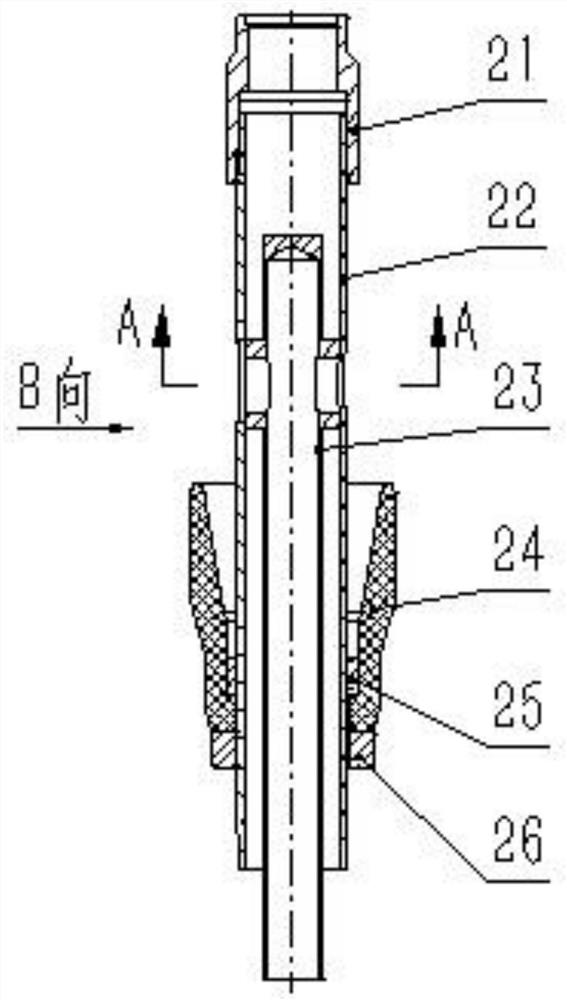

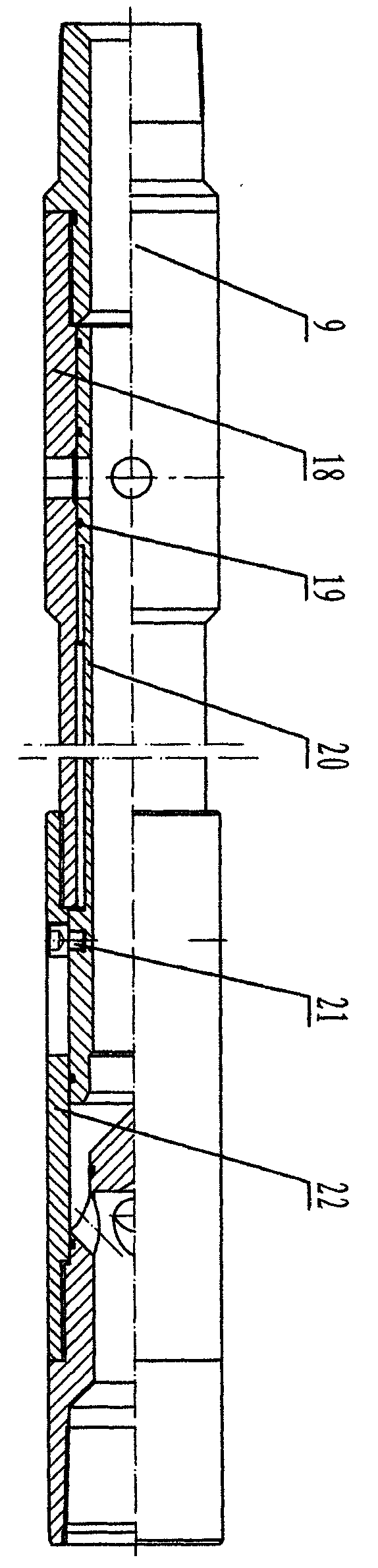

Multi-formation fracturing device and process of release tubular column

InactiveCN101638982AImprove work efficiencyImprove reliabilityDrilling rodsFluid removalWater wellOil well

The invention relates to a multi-formation fracturing technology of oil, oil wells of gas fields, gas wells or water injection wells, in particular to a multi-formation fracturing device and a process of a release tubular column. The device at least comprises a sliding sleeve seat, a sand ejector, a stage oil pipe, packers, a release joint and an oil conveying pipe, wherein the sand ejector is connected with the sliding sleeve seat through threads and positioned on the sliding sleeve seat; the sand ejector is also connected with the packers through an oil pipe in the middle to form a layer offracturing tubular columns; the packer of the tubular columns on a front layer and the packer of the tubular columns on a rear layer are connected through threads and positioned on the packer of a forward stage; and the packer of a backward stage is connected with the release joint and then connected with the oil conveying pipe through the release joint. The process flow of the invention is completed through eleven steps, thereby realizing the continuous fracturing operations of multiple oil and gas formations of a slim hole and a horizontal well.

Owner:CNPC SICHUAN GASOLINEEUM GEOPHYSICAL PROSPECTING ENG TECH RES INST

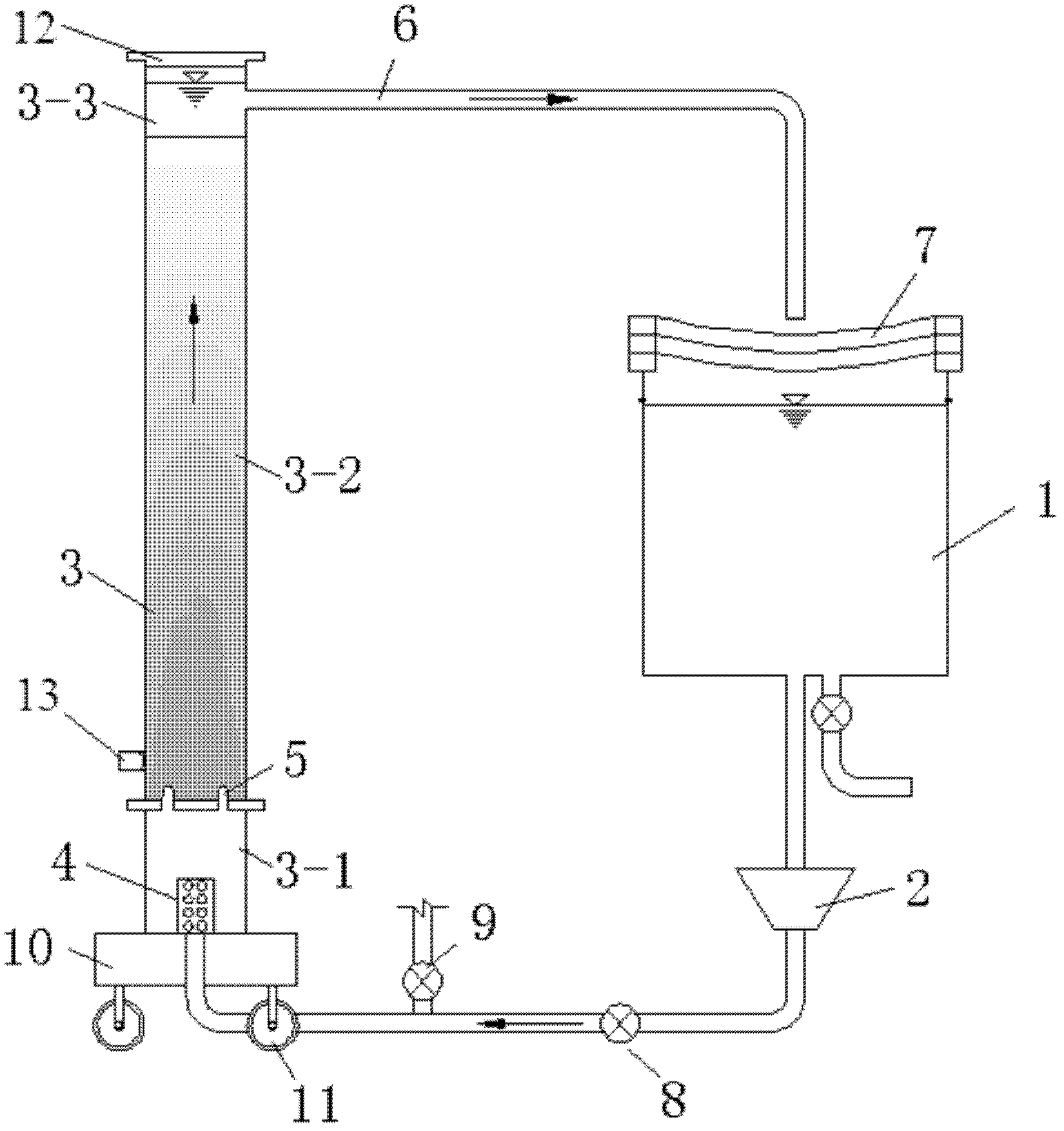

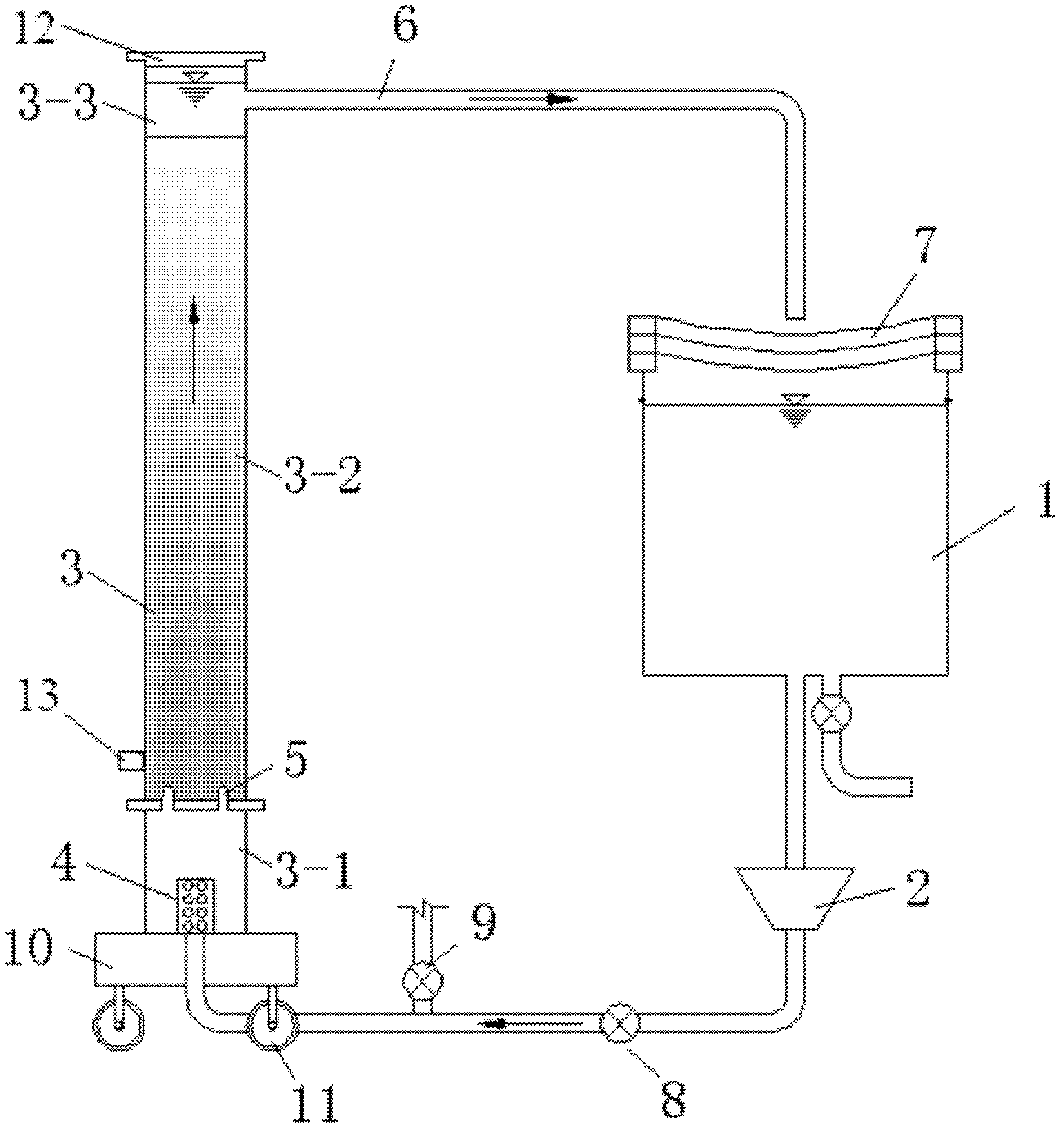

Sand washing method and special device thereof

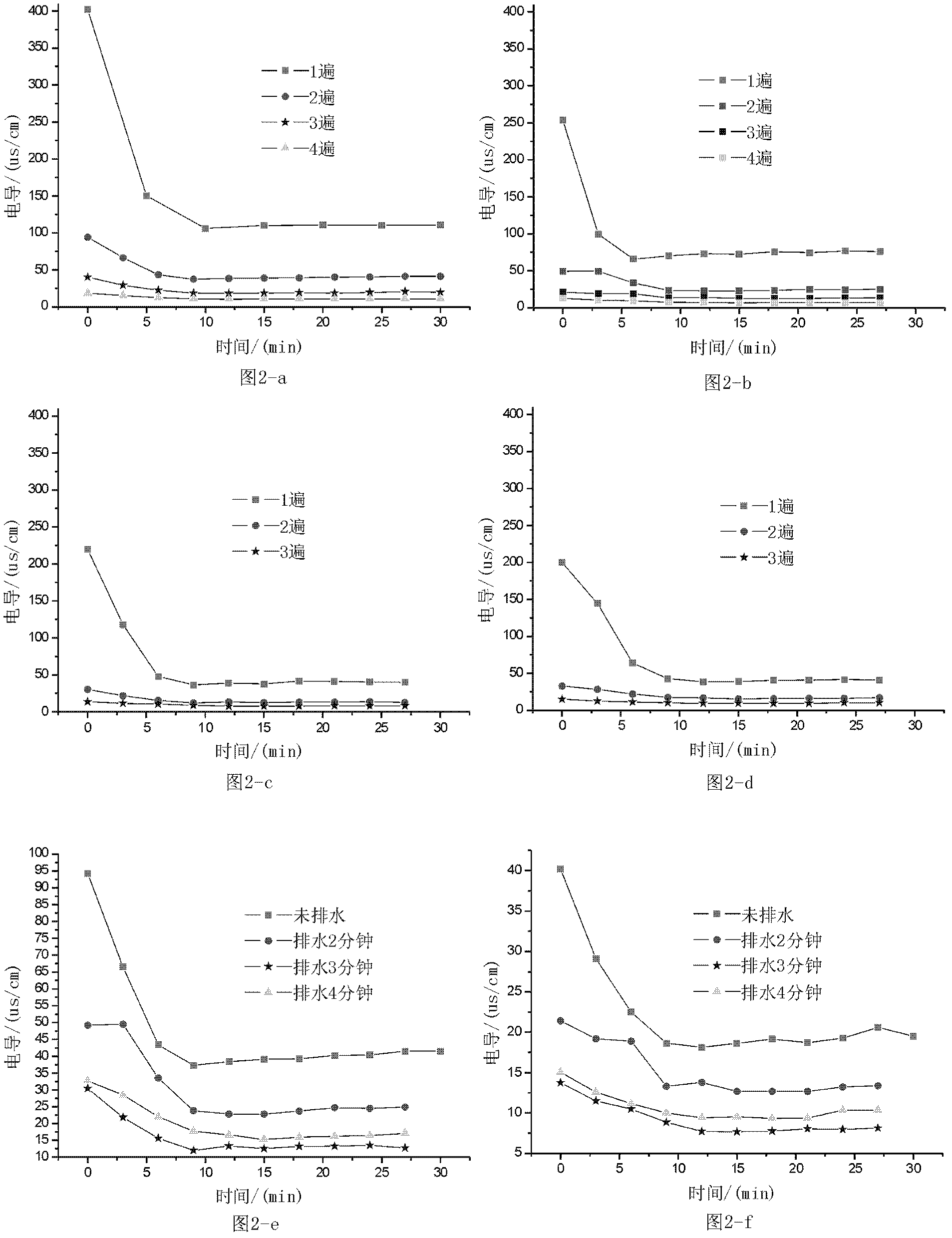

ActiveCN102500458AGood quicksand stateImprove sand washing effectWet separationMicroorganismWater flow

The invention discloses a sand washing method, which comprises following steps: sand filling, washing, or / and pickling or / and alkali washing, deionized water cleaning, sand storage and the like. The invention further discloses a special device for the sand washing method. The sand washing device comprises a sand column tube and a water tank, the sand column tube is divided into a water inlet buffering area, a sand column area and an overflow area according to a water flowing direction, the water inlet buffering area is separated from the sand column area via four water distribution caps which are annularly uniformly distributed, a cylindrical buffering device is mounted on the water inlet buffering area, an inner cylinder of the cylindrical buffering device is in through connection with a water outlet of the water tank via a water delivery pipe, the overflowing area is provided with an overflowing pipe, a water outlet of the overflowing pipe is suspended above a liquid inlet of the water tank, and a filtering screen is mounted at the liquid inlet of the water tank. By the aid of organic combination of the deionized water cleaning, the pickling and the alkali washing to sand, metal ions, colloid particles, microorganisms and other impurities in the sand are effectively removed.

Owner:HOHAI UNIV

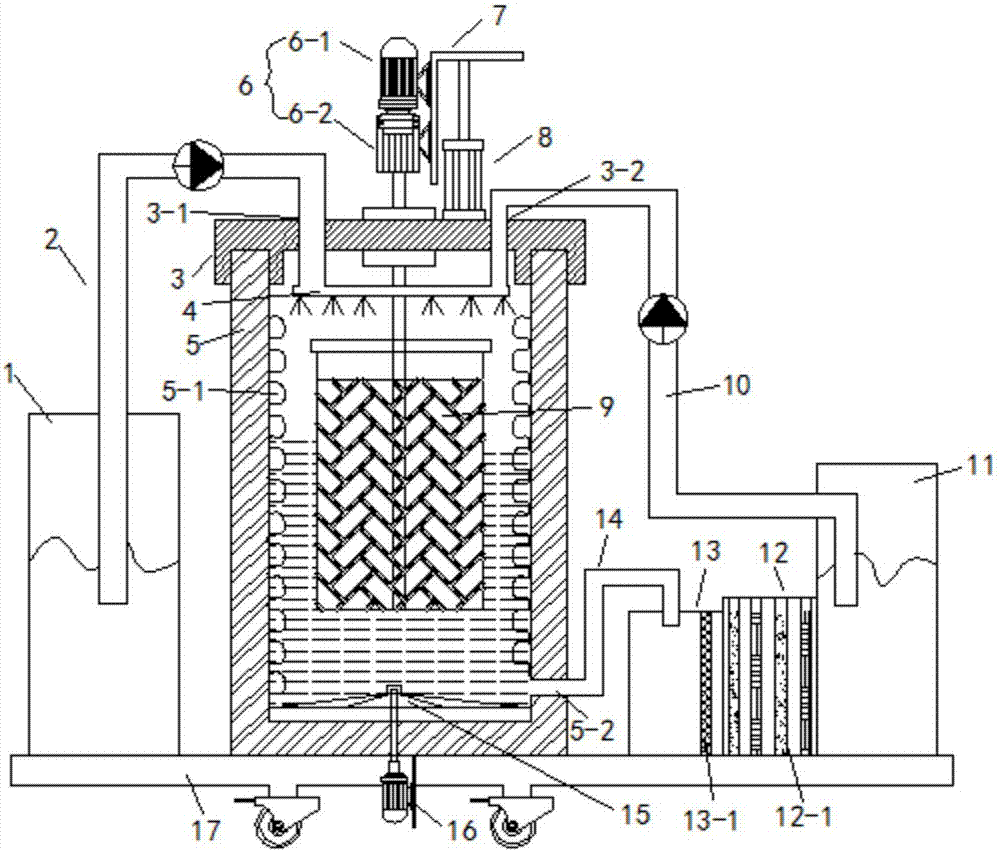

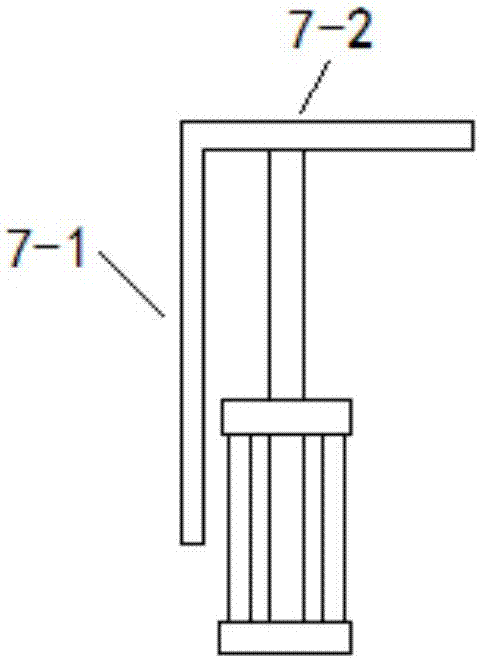

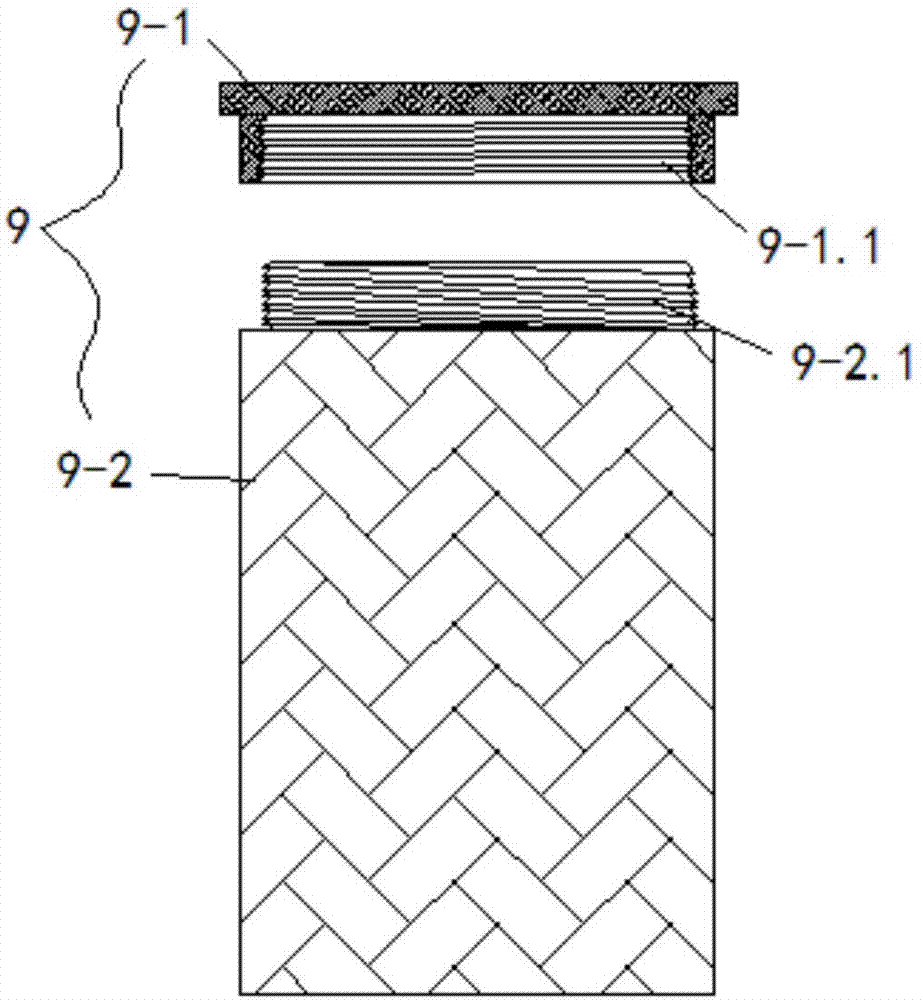

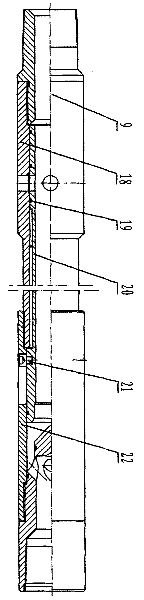

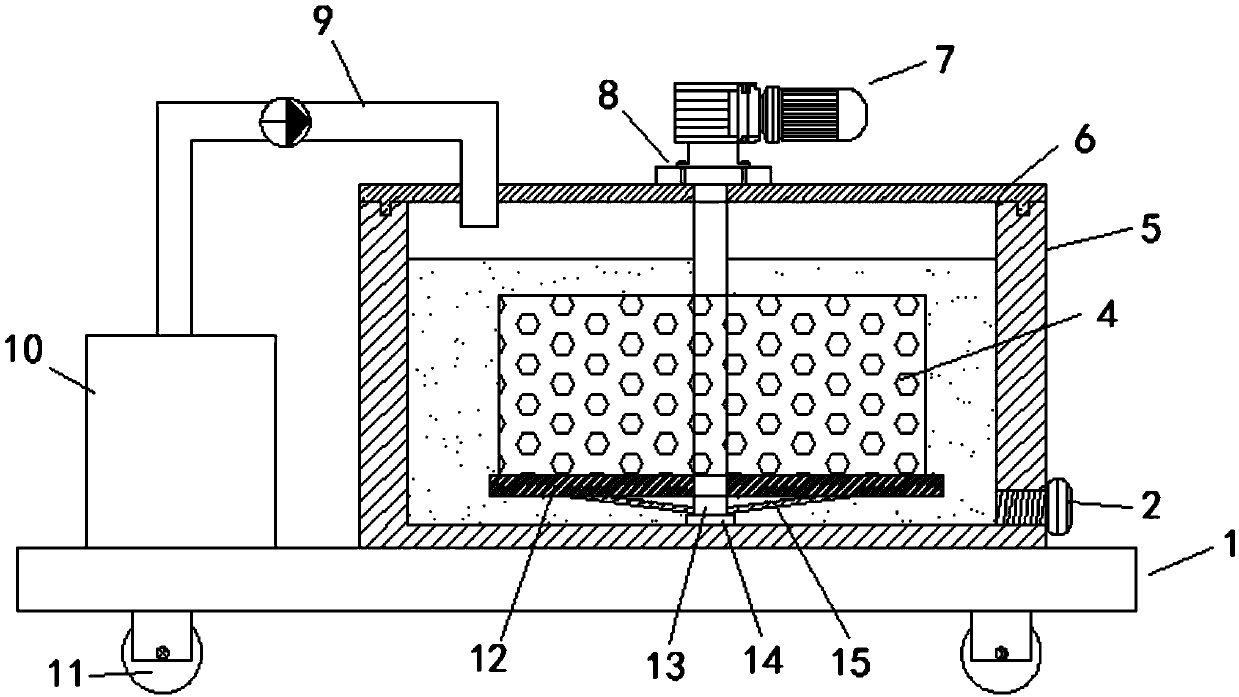

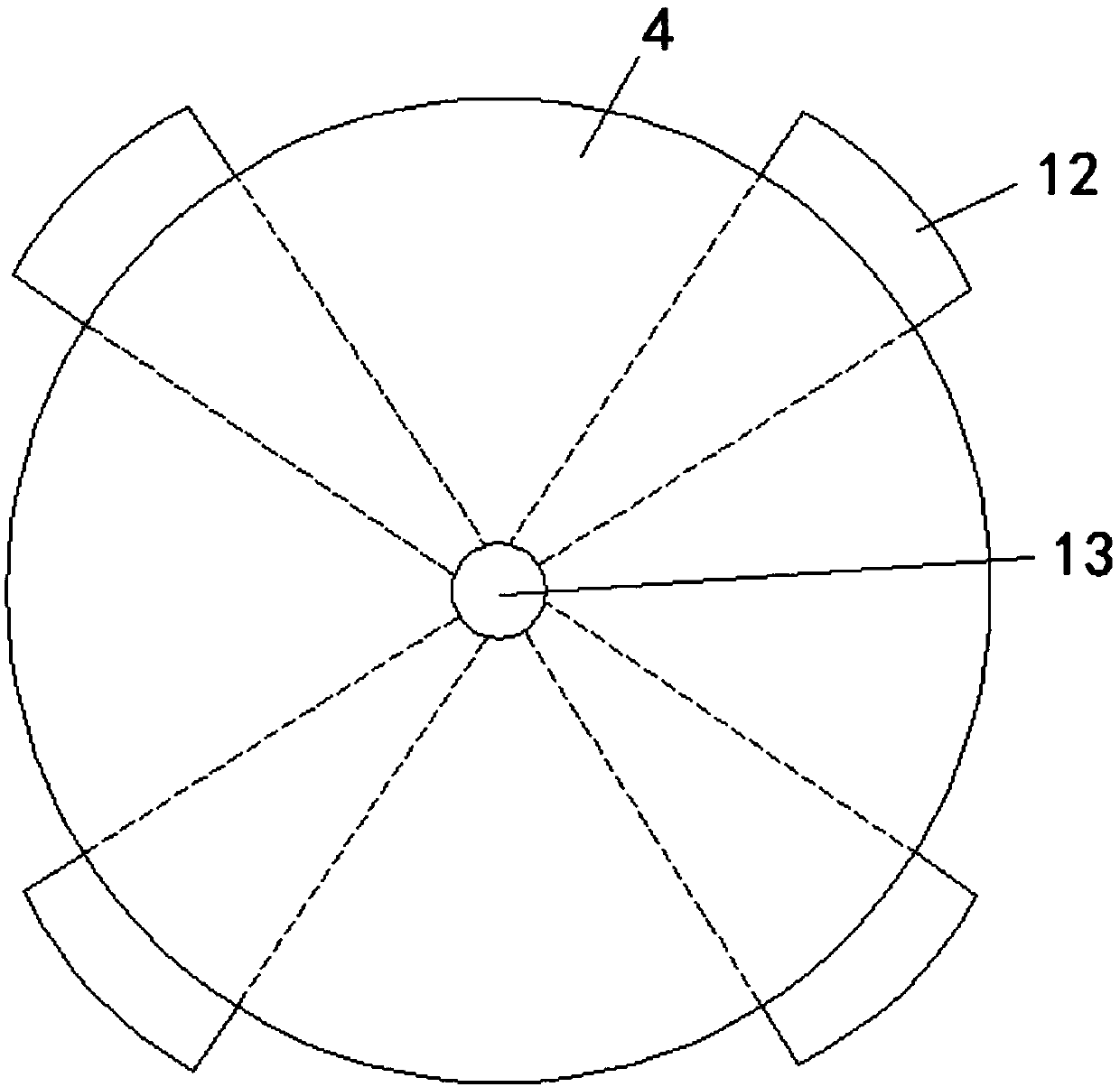

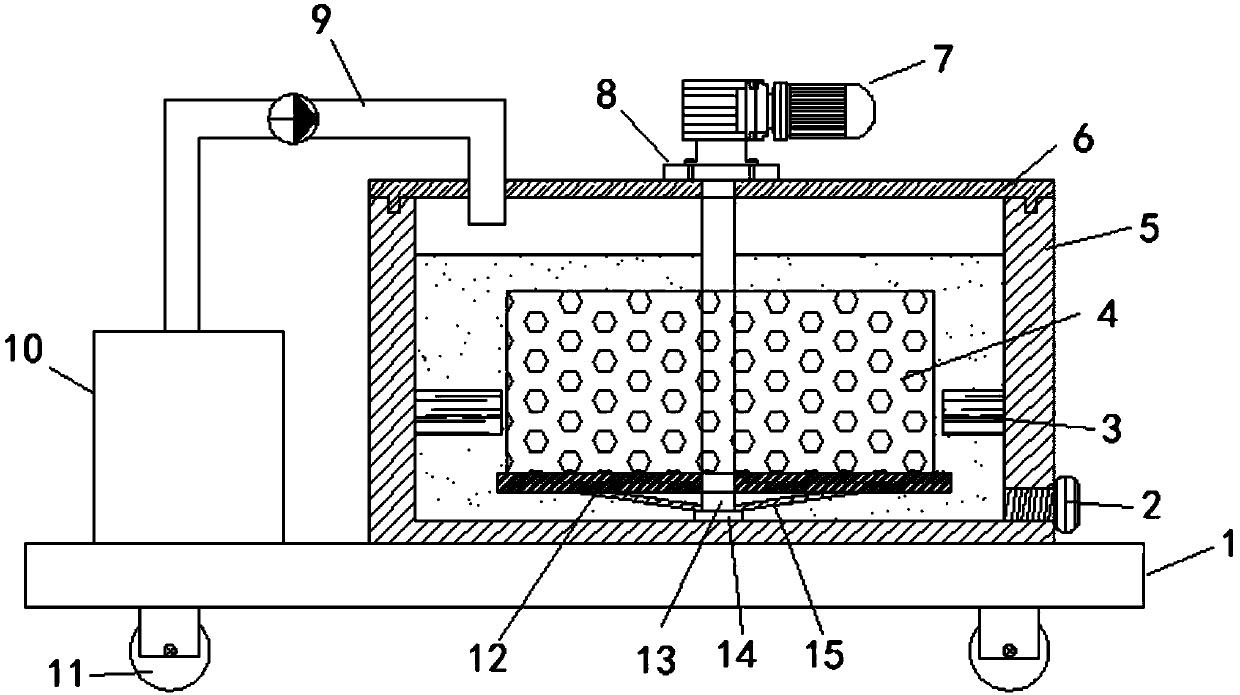

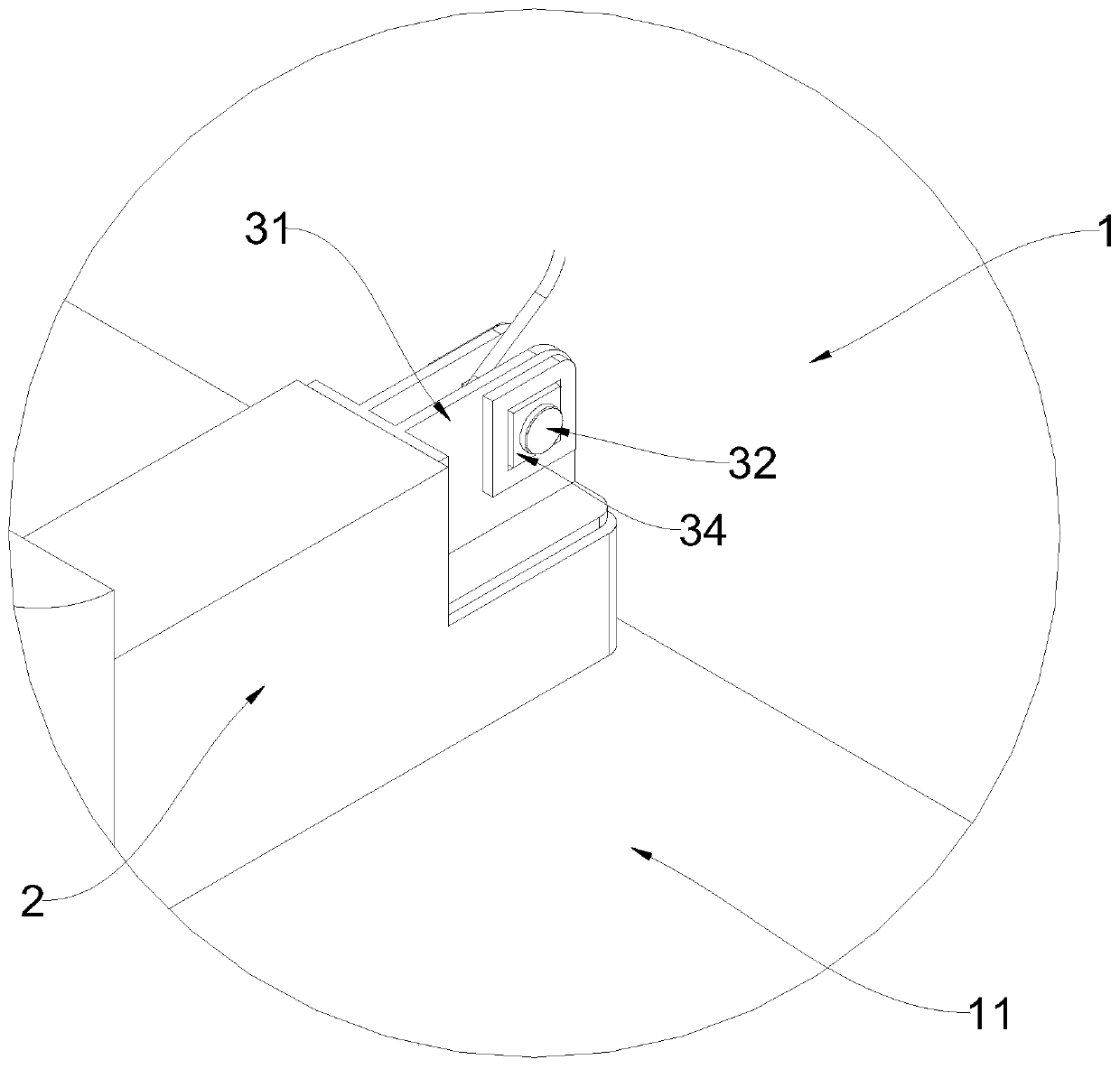

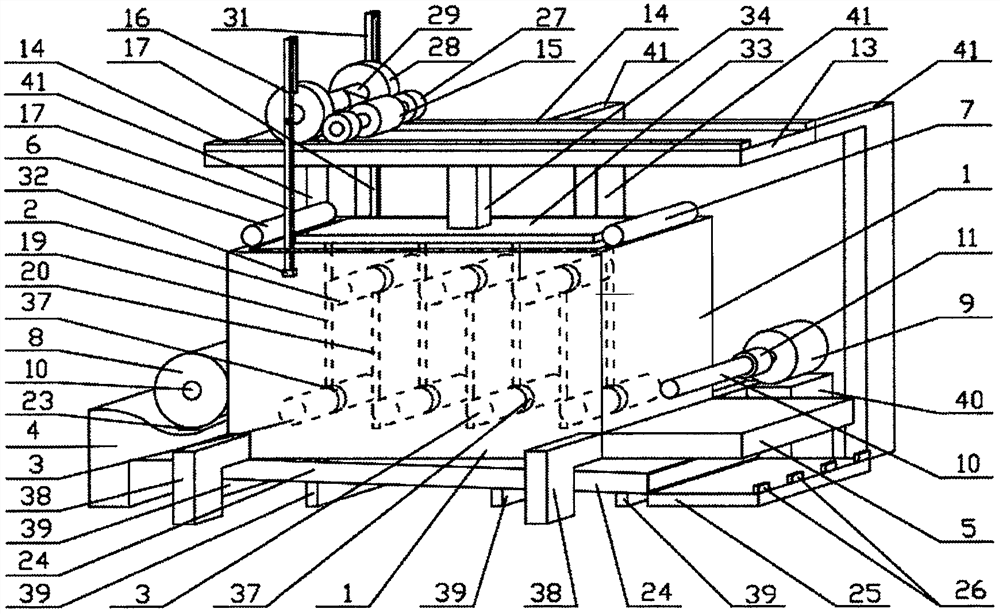

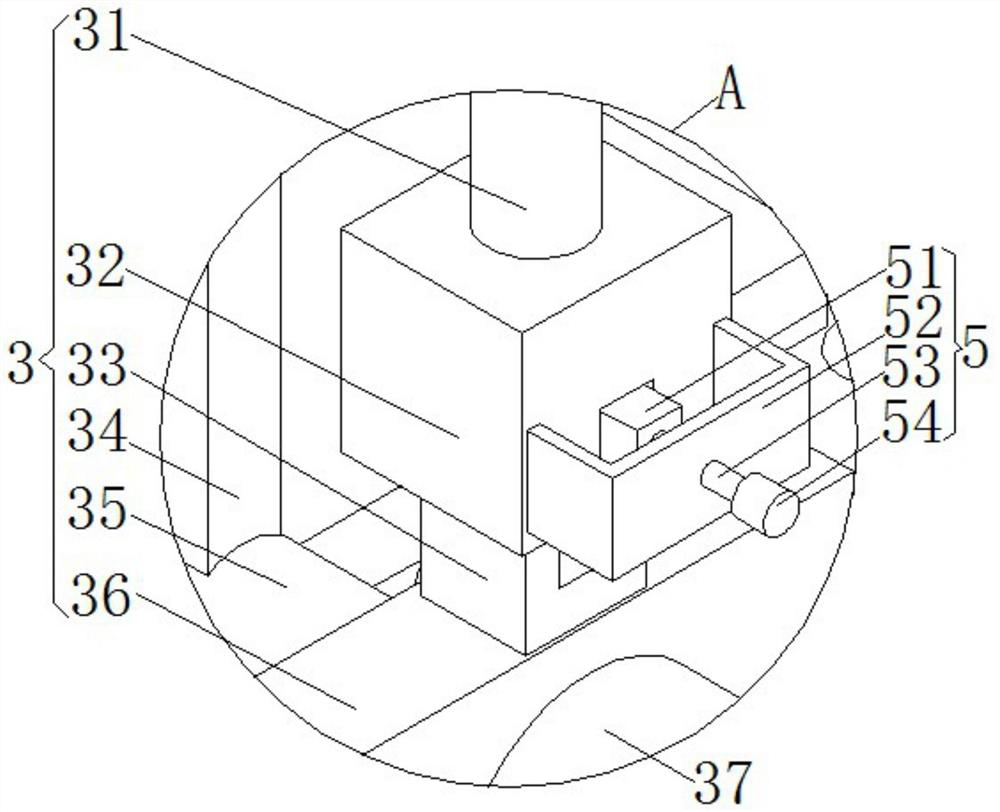

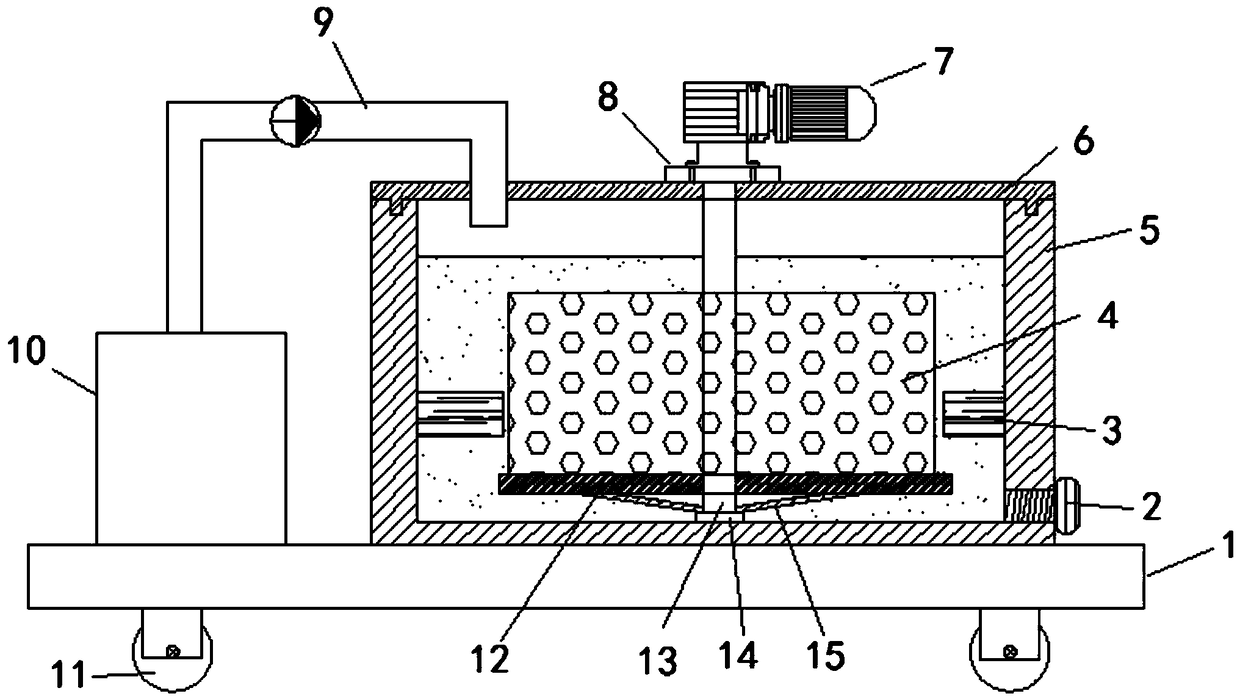

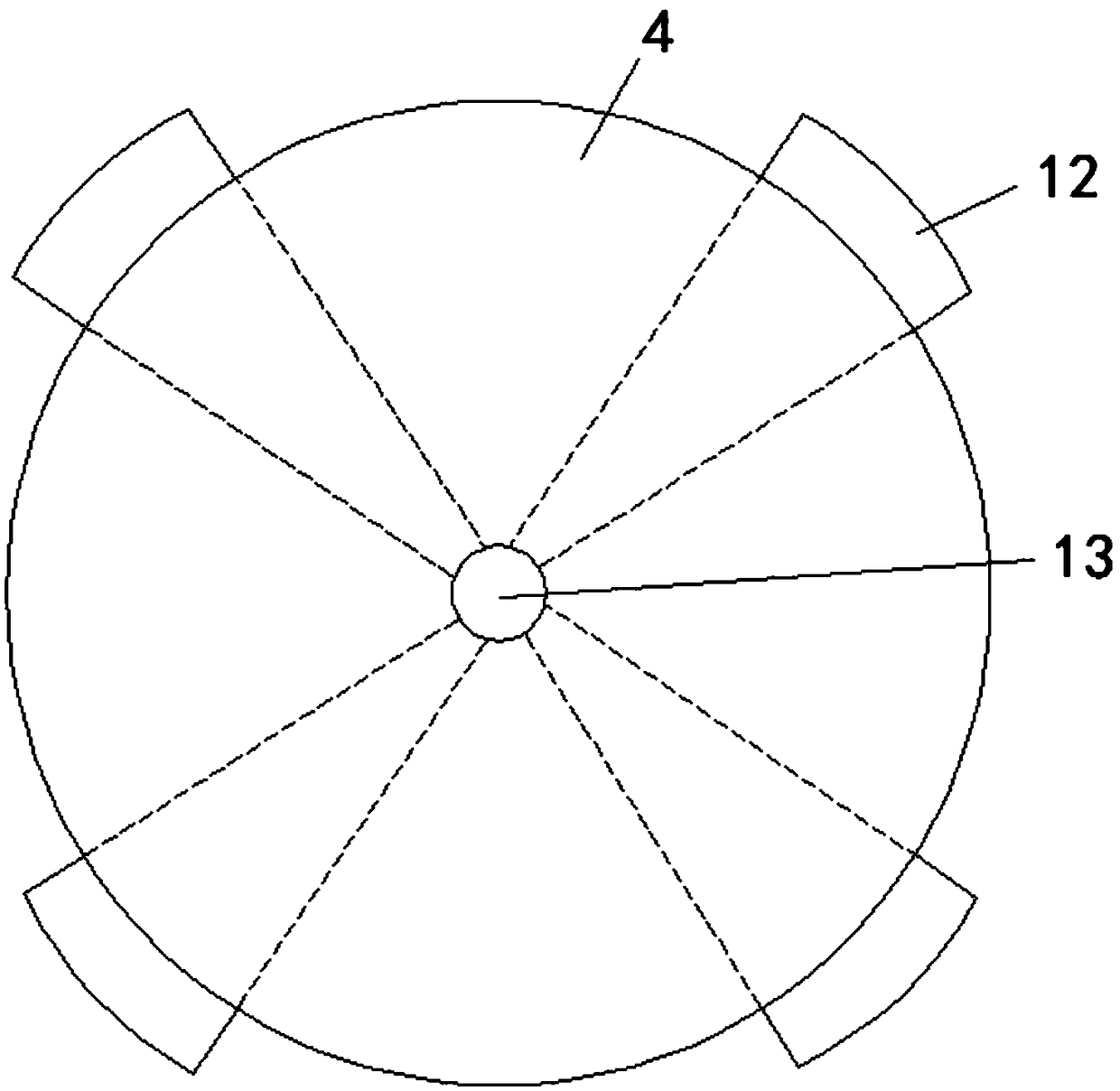

Movable well logging sand washing device

InactiveCN107398341AImprove sand washing efficiencyImprove sand washing effectHollow article cleaningTreatment involving filtrationEngineeringOil field

The invention discloses a movable well logging sand washing device and relates to the technical field of oil field well logging equipment. The movable well logging sand washing device comprises a movable base, a sand cleaning pond located on the movable base, and a sand containing barrel located in the sand cleaning pond; the sand cleaning pond is provided with a cover plate which is provided with a water inlet in an excavating manner; the water inlet is communicated with an annular water spraying pipe located in the sand cleaning pond, and the inner diameter of the annular water spraying pipe is larger than the outer diameter of the sand containing barrel; the lower end of the pond wall of the sand cleaning pond is provided with a water outlet; the cover plate is provided with a rotating driving assembly and a lifting driving assembly driving the rotating driving assembly to move up and down; and the output end of the rotating driving assembly penetrates the cover plate, extends into the sand cleaning pond, and penetrates the top of the sand containing barrel to be fixedly connected with the top and the bottom of the sand containing barrel. According to the movable well logging sand washing device, the two driving assemblies are used for driving the sand containing barrel to rotate up and down in the sand cleaning pond containing clean water, rock debris and a mud mixture in the sand containing barrel are made to be separated to achieve the sand washing purpose, and the sand washing effect is ideal.

Owner:成都捷科菲友信息技术有限公司

Environment-friendly polyester fabric sand washing dyeing process

InactiveCN106087470AImprove dyeing effectEnhanced stainingFibre typesDyeing processInorganic saltsFiber

The invention discloses an environment-friendly polyester fabric sand washing dyeing process. A one bath process is selected to dye polyester fiber, dyeing and sand washing are completed by one time, at the same time anhydrous sodium sulphate and other inorganic salts are unnecessary, thus reaching environmental protection and energy saving effects; marble sandstones are selected for sand washing, firstly, the polyester surface can be ground to enhance the dyeing effect, secondly the fabric seems to have a natural and friendly dyeing effect, and thirdly only through simple pickling of the fabric in follow-up treatment, the harm of tiny granules to the human body can be eliminated. And by using plant dyes, the process is environment-friendly and healthy. The environment-friendly polyester fabric sand washing dyeing process provided by the invention is a healthy, environment-friendly and energy-saving novel dyeing process.

Owner:绍兴市柯桥区众诚印染有限公司

Sand washing device for filtration system

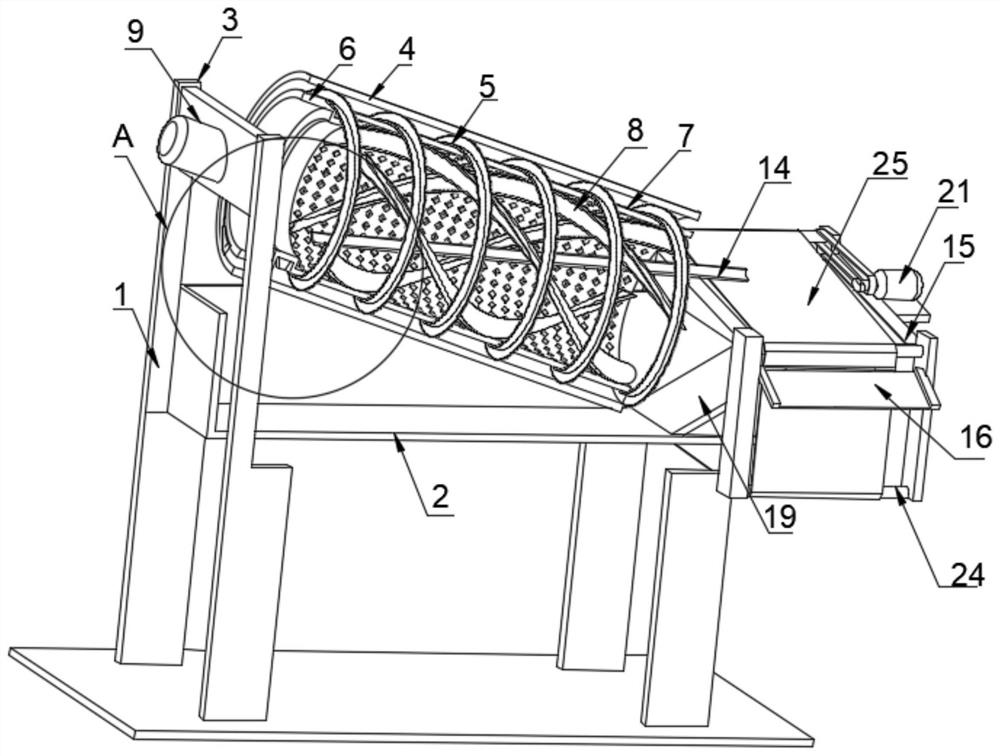

InactiveCN108746051AAvoid blockingIncreased Friction DecontaminationCleaning using liquidsFiltrationSpiral blade

The invention discloses a sand washing device for a filtration system. The sand washing device comprises a device body, a shell, a stirring shaft, a driven gear, a motor, a fan, a bulge and a sand washer main body. The shell is arranged at one end of the device body. The sand washing device is scientific and reasonable in structure, by arranging the motor and the fan, the motor is started to drivea rotating shaft to rotate, the stirring shaft drives stirring blades to stir sand, meanwhile, the fan blows air into an aerator pipe, the aerator pipe outwards blows the air, thus dirt in the sand is upwards floated along with stirring, the dirt or the dirty sand enters the sand washer main body and is spirally stirred through an internal spiral blade when passing through a sand washing channel,and the sand is mutually rubbed to remove the dirt; and compared with traditional modes that the dirt is removed only through friction between the sand and meanwhile the sand washing channel is proneto being blocked, the stirring shaft rotates to enable the spiral blade to rotate to increase friction between the sand, and the sand is effectively prevented from blocking the sand washing channel while the dirt is removed.

Owner:WUHU CHAOYUANLI IND DESIGN CO LTD

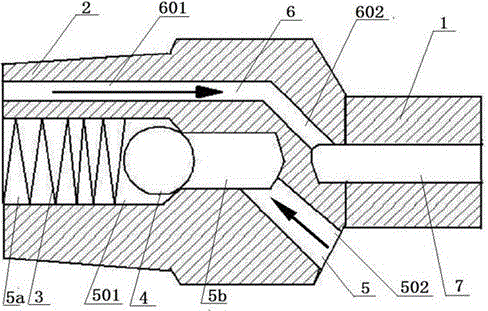

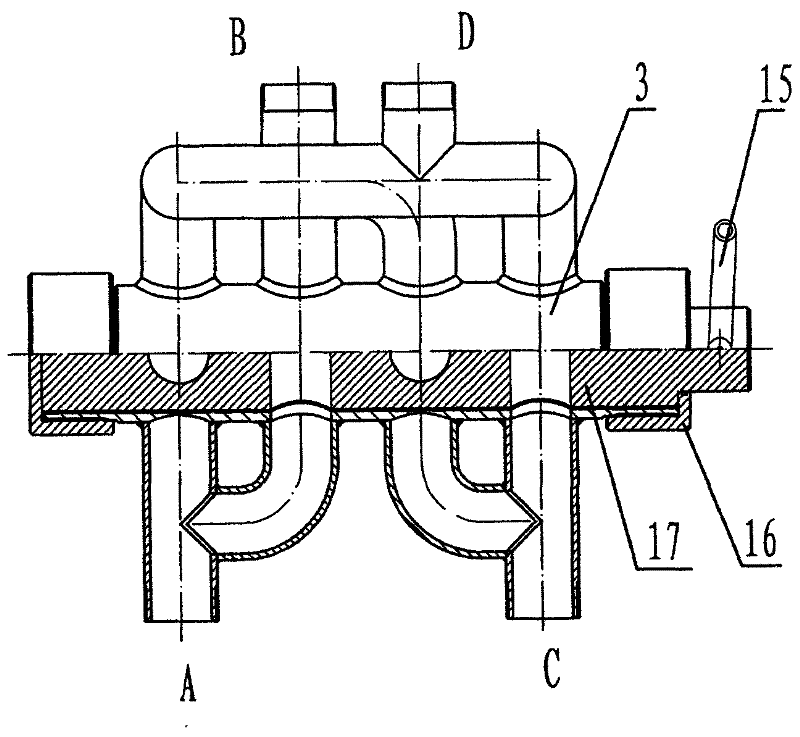

Two-way passageway check valve and method for conducting sand-flushing through the same

The invention provides a two-way passageway check valve and a method for conducting sand-flushing through the two-way passageway check valve. The two-way passageway check valve is connected between a rotating jetting sand flushing device and an oil pipe. An upper connector used for being connected with the rotating jetting sand flushing device is arranged at the upper end of the two-way passageway check valve, and a lower connector used for being connected with the oil pipe is arranged at the lower end of the two-way passageway check valve. A diversion passageway is arranged in the upper connector. A forward passageway is arranged at the inner upper end of the lower connector, and a reverse passageway is arranged in the inner lower end of the lower connector. A valve ball and a spring are arranged in the reverse passageway. Compared with an existing liquid backflow passageway oil sleeve annulus, the passageway section is obviously narrowed, the liquid backflow speed is obviously increased, the liquid backflow speed is effectively increased under the condition of the same delivery capacity, the shaft sand grain suspension and backflow of a horizontal well section are facilitated, and the horizontal wall sand flushing effect is improved.

Owner:PETROCHINA CO LTD

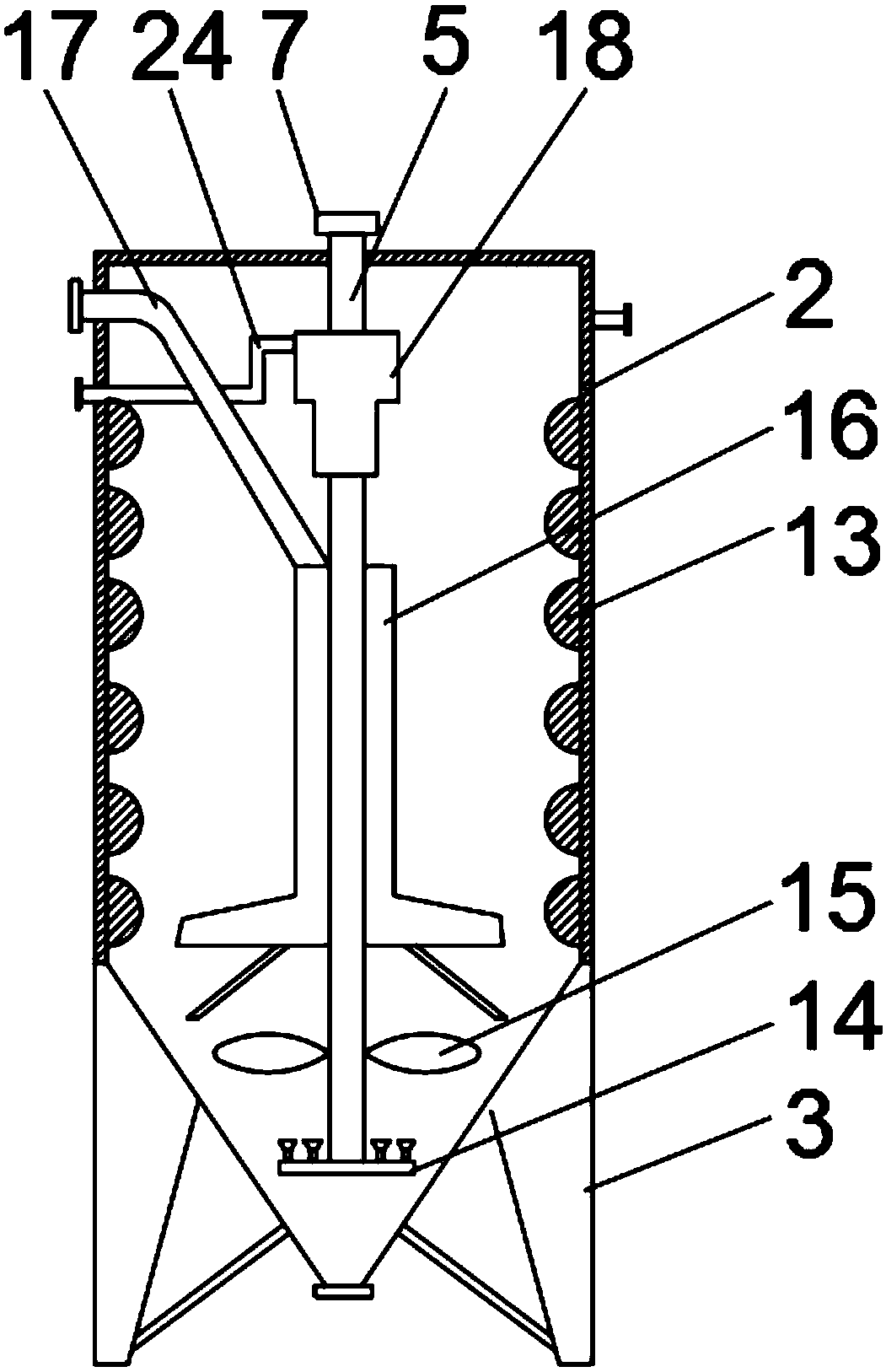

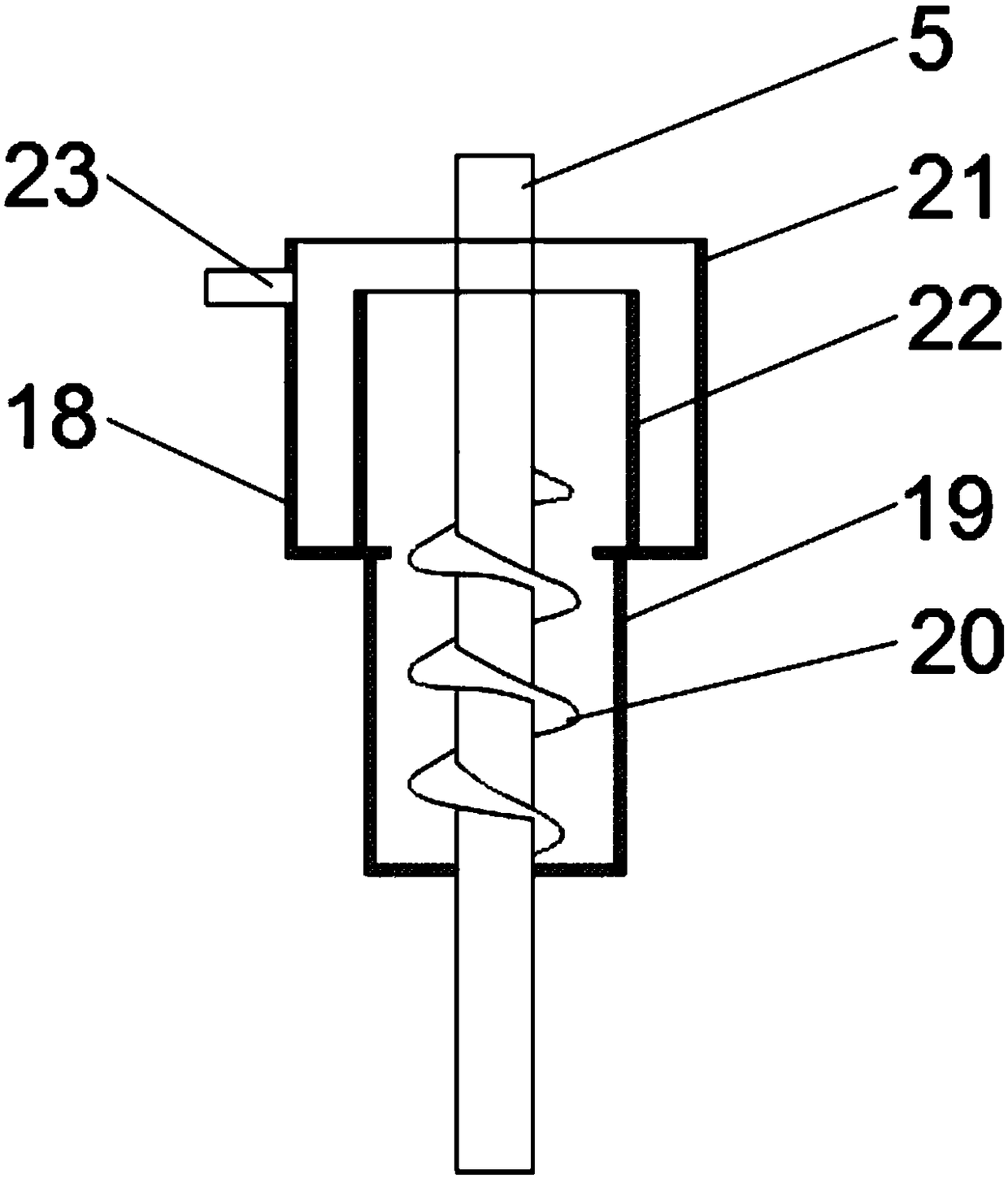

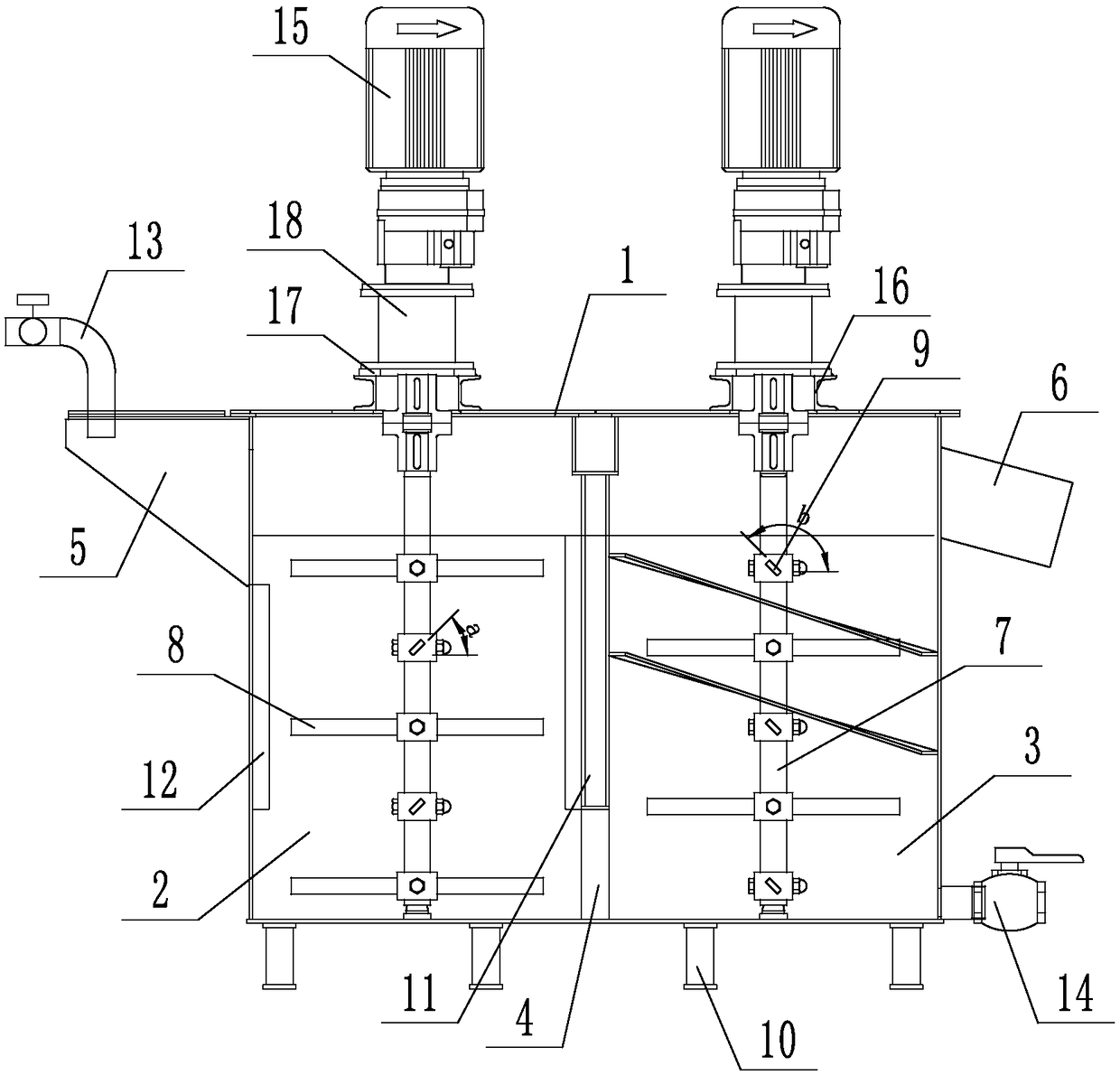

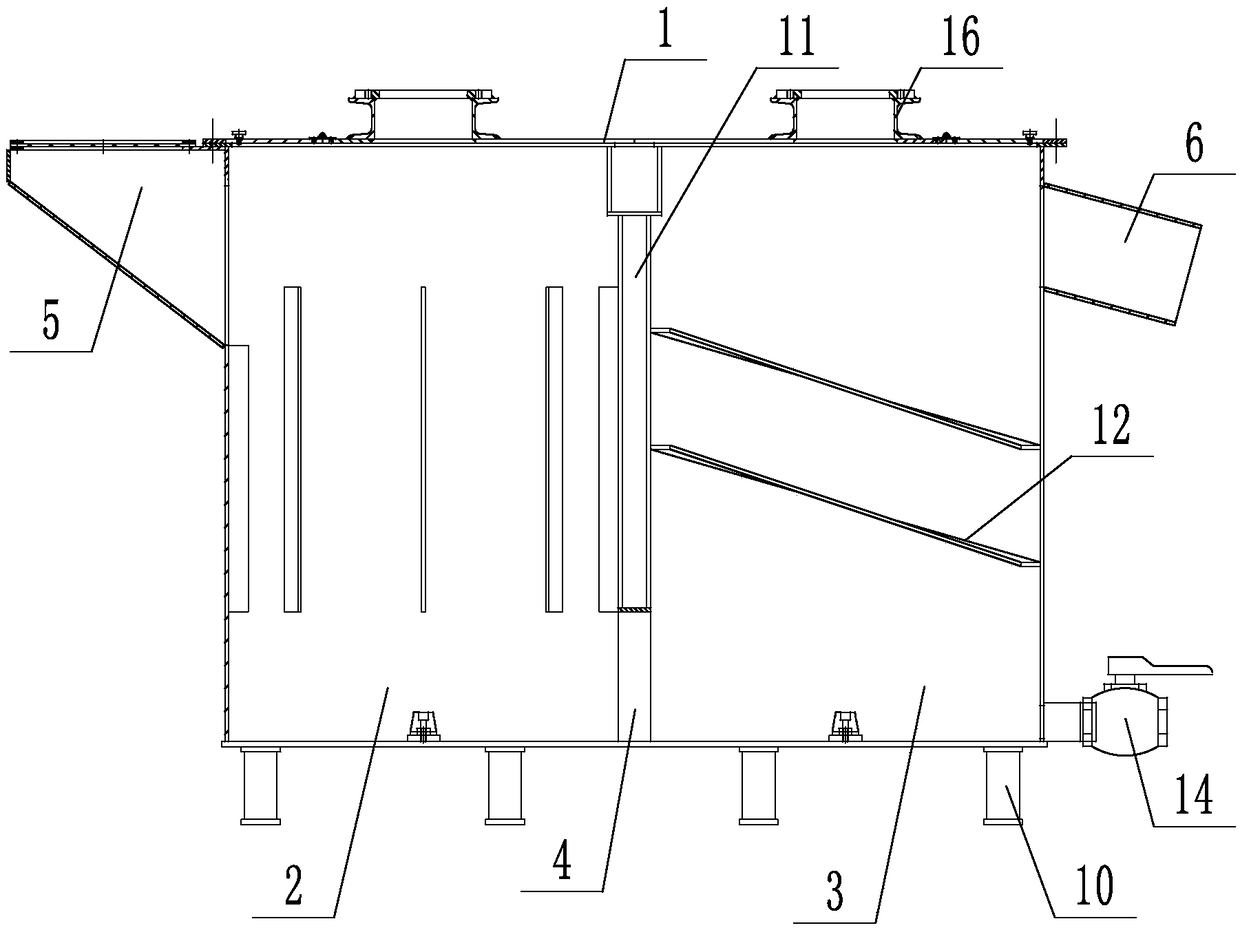

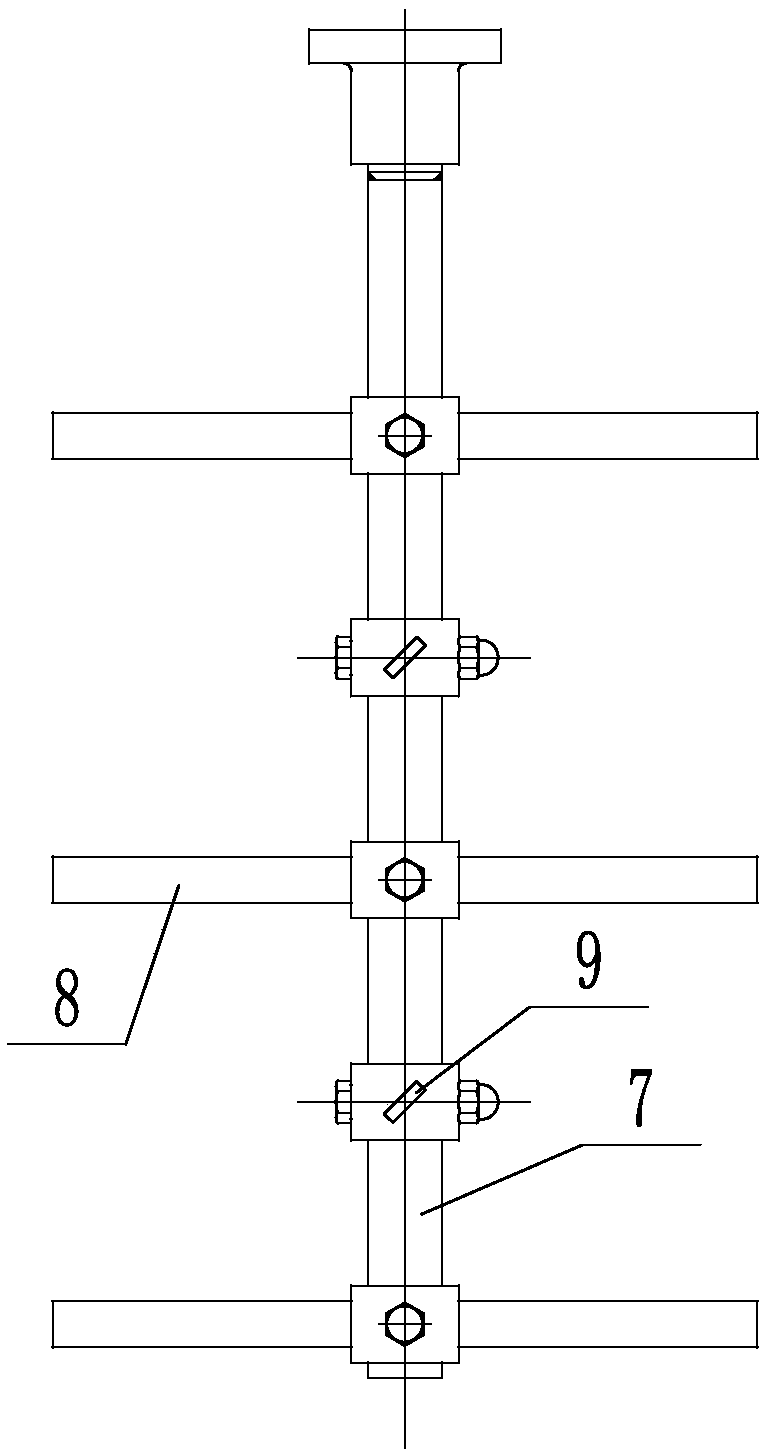

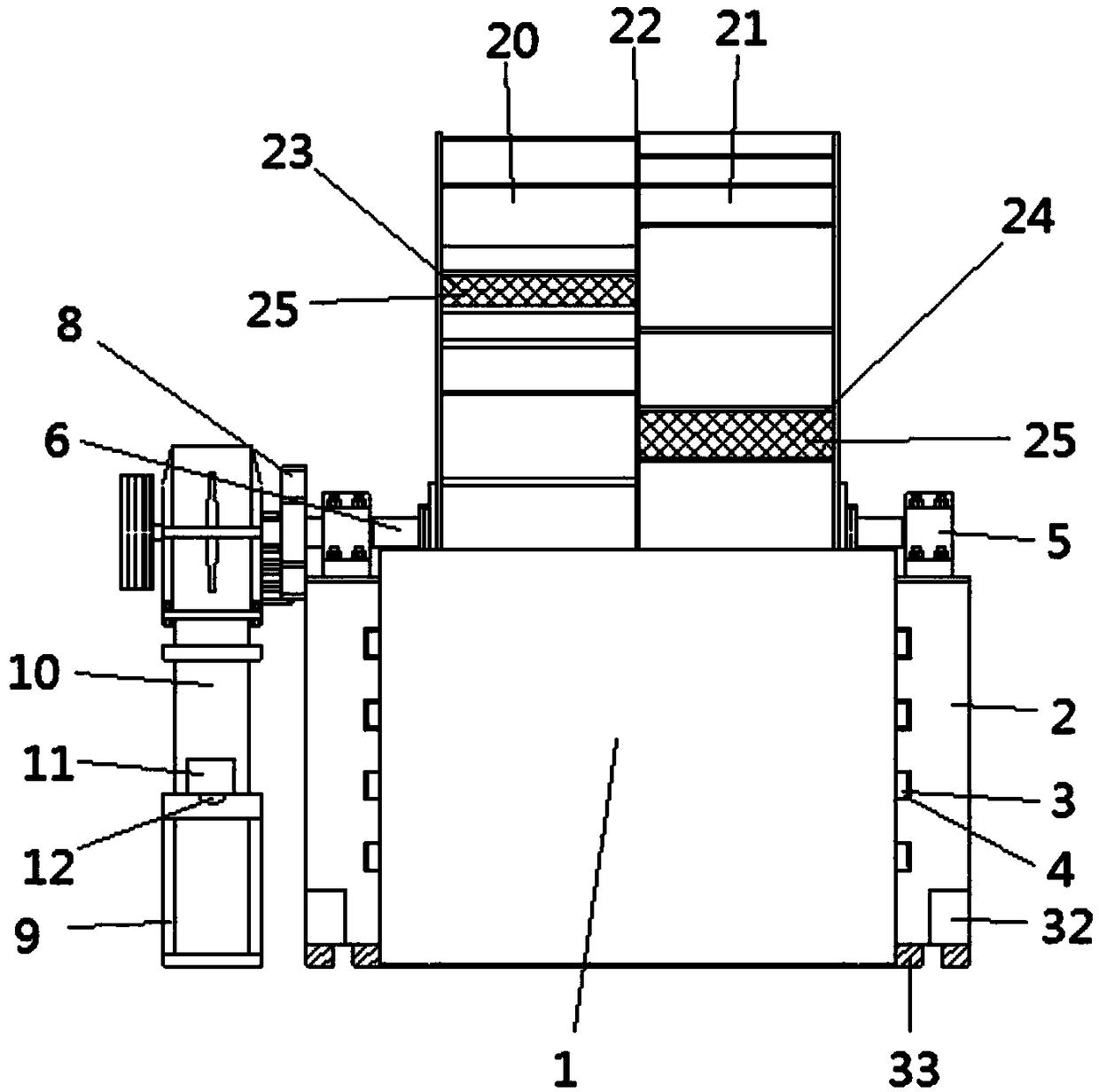

Two-stage vertical type sand washer

PendingCN108906774AFree from destructionCompact structureCleaning using liquidsEngineeringEnergy source

The invention discloses a two-stage vertical type sand washer. The two-stage vertical type sand washer comprises a barrel body, sand washing systems and driving systems, the barrel body adopts a vertical barrel type structure and comprises a primary stirring barrel and a secondary stirring barrel, an opening is arranged between the primary stirring barrel and the secondary stirring barrel, the primary stirring barrel is provided with a material inlet, the secondary stirring barrel is provided with a material outlet, the primary stirring barrel and the secondary stirring barrel are both internally provided with one sand washing system, the sand washing systems adopt blade type sand washing mechanisms, each sand washing system comprises a main shaft, vertical sand washing blades and inclinedsand washing blades, and the main shafts are rotatably connected with the corresponding primary stirring barrel and secondary stirring barrel. According to the two-stage vertical type sand washer, the blade type sand washing mechanisms of the vertical sand washing blades and the inclined sand washing blades are adopted, no damage is caused to sand, the barrel body adopts the vertical barrel typestructure, the two-stage vertical type sand washer is compact in structure, the installation space is saved, with the help of the flow characteristic of flow liquid, water can drive the sand to flow together under the action of the inclined sand washing blades, and energy sources are saved.

Owner:JIER MACHINE TOOL GROUP

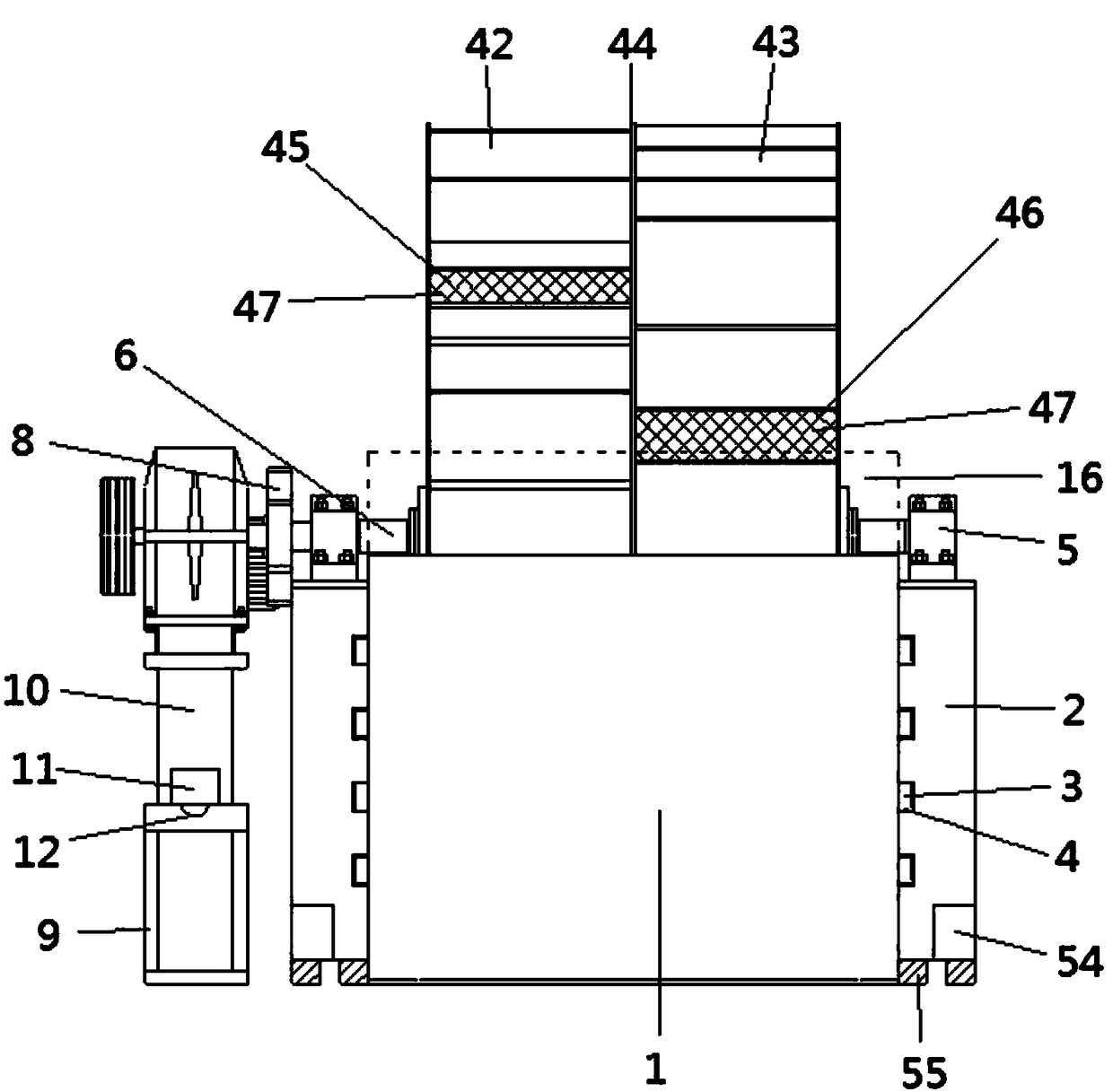

Sand washing device good in sand washing effect

The invention discloses a sand washing device good in sand washing effect. The sand washing device good in sand washing effect comprises a sand washing groove; the two sides of the sand washing grooveare each connected with a movable platform; the side walls of the movable platforms are provided with a plurality of sliding guide rails arranged in parallel; the side wall of the sand washing grooveis provided with a guide rail sliding strip matched with the sliding guide rails; a wheel shaft installing base is fixed to each movable platform; a wheel shaft is arranged between the two wheel shaft installing bases; am impeller set is erected in the sand washing groove through the wheel shaft; a fixed supporting base is arranged on the outer side of the sand washing groove, and is provided with a movable supporting base; the fixed supporting base is provided with an electric-hydraulic pushing rod connected with the movable supporting base; the upper surface of the fixed supporting base isprovided with a slide groove; the lower surface of the movable supporting base is provided with a slider matched with the slide groove; a sand outflow plate is connected to the sand washing groove; avibrating screen is arranged below the sand outflow plate; a water tank is connected below the vibrating screen through a pair of telescopic rods; and a recycling box is arranged on one side of the water tank. The sand washing device good in sand washing effect has the beneficial effect of being good in sand washing effect.

Owner:湖州众创小微创业园企业管理股份有限公司

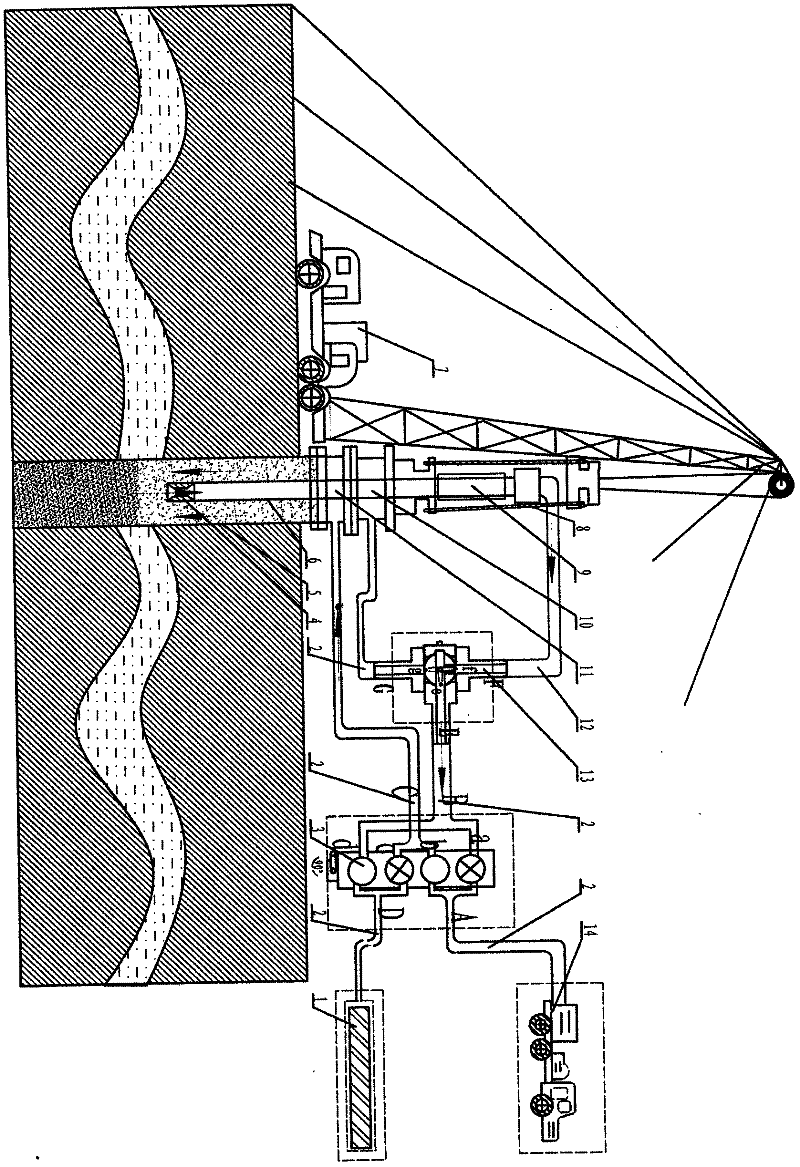

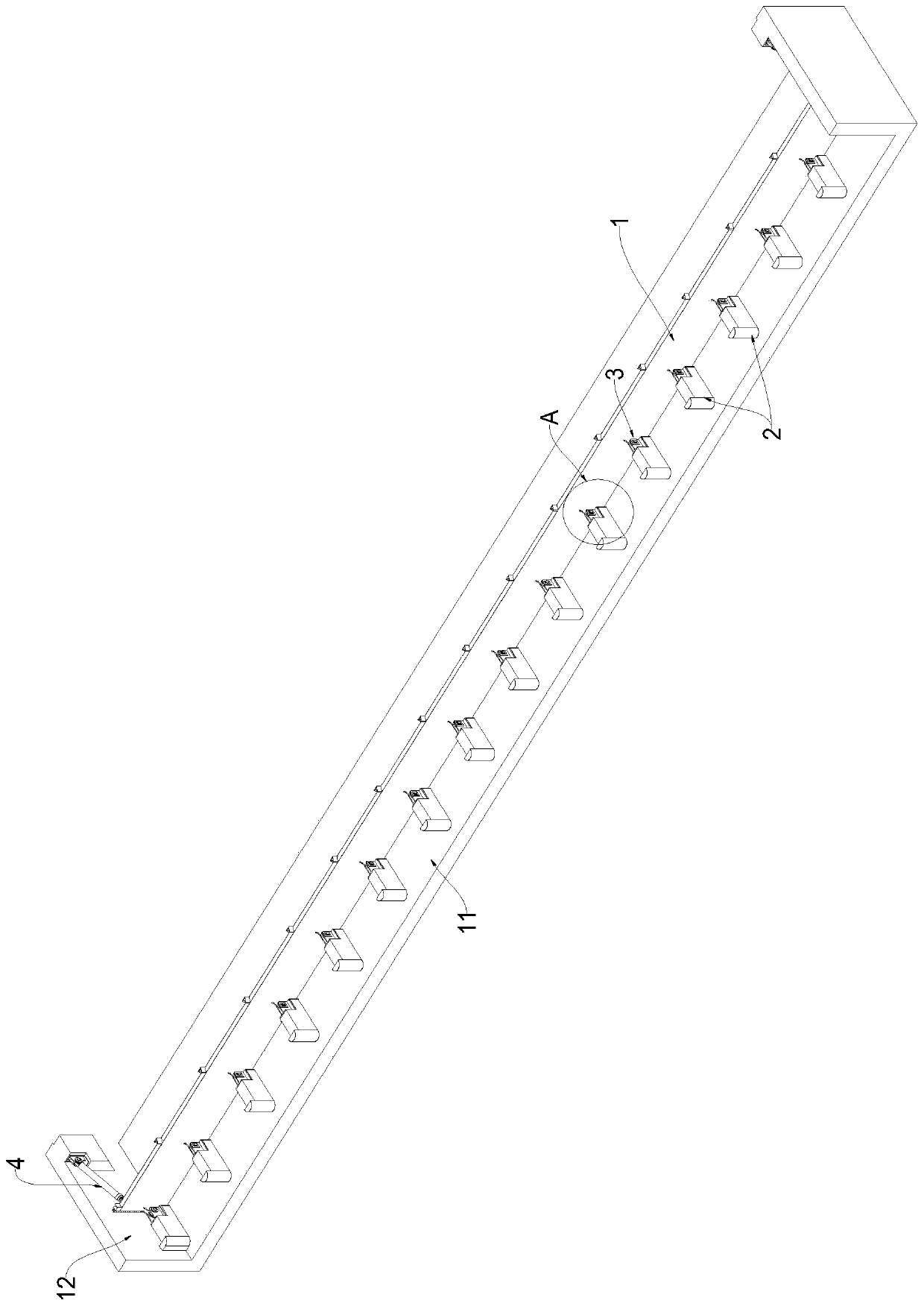

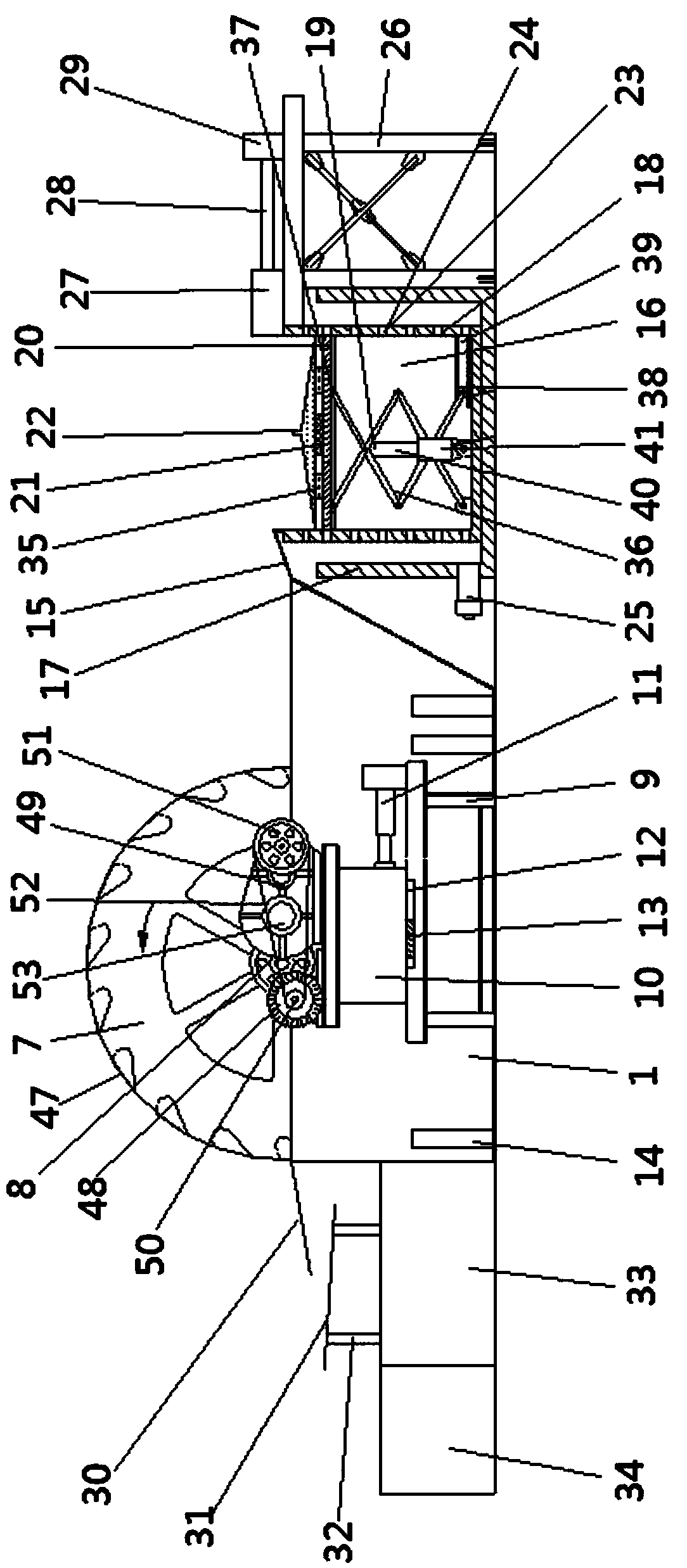

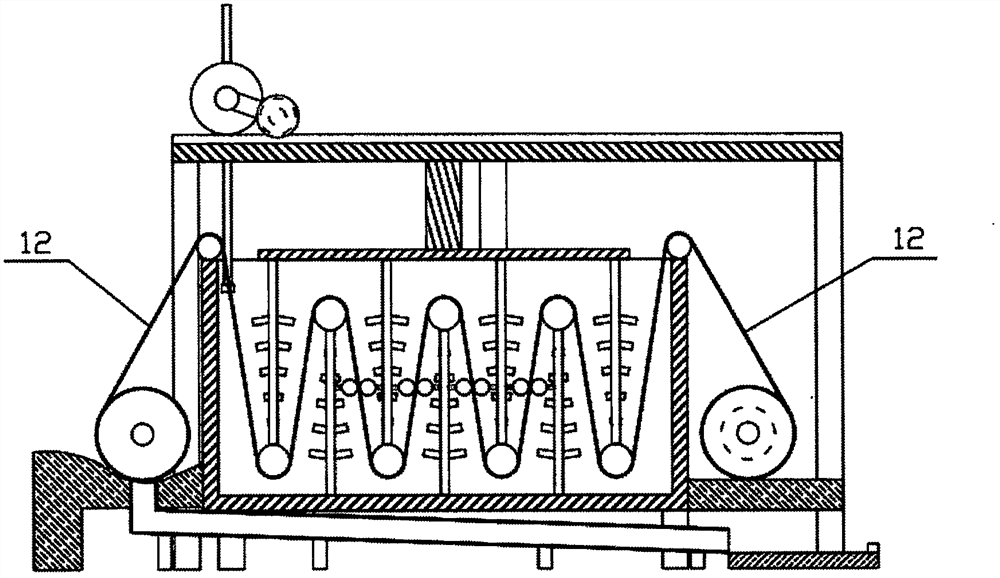

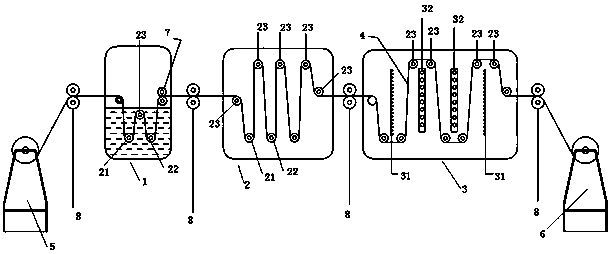

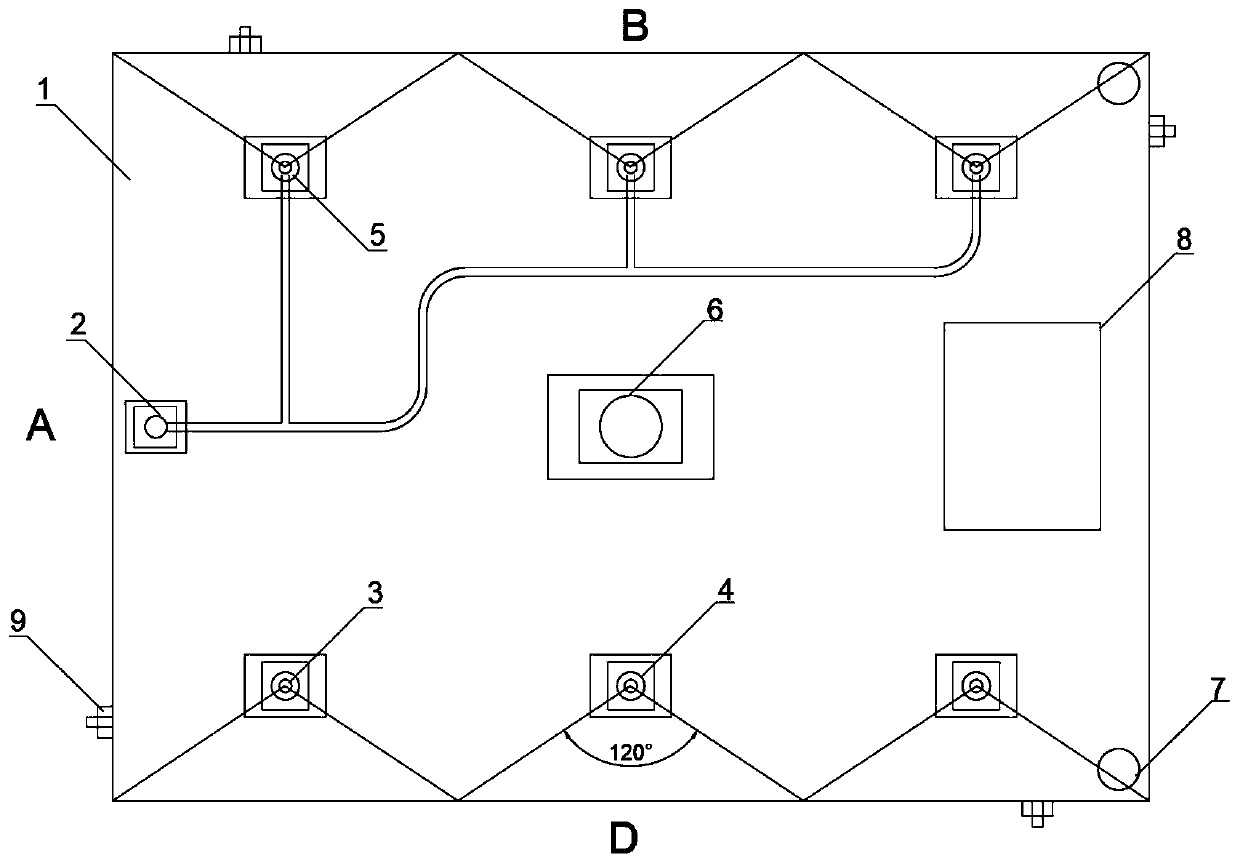

Continuous positive and negative integrated sand washing device for oil well

ActiveCN102383750ASatisfy sand washing requirementsImprove sand washing effectFlushingOil waterEngineering

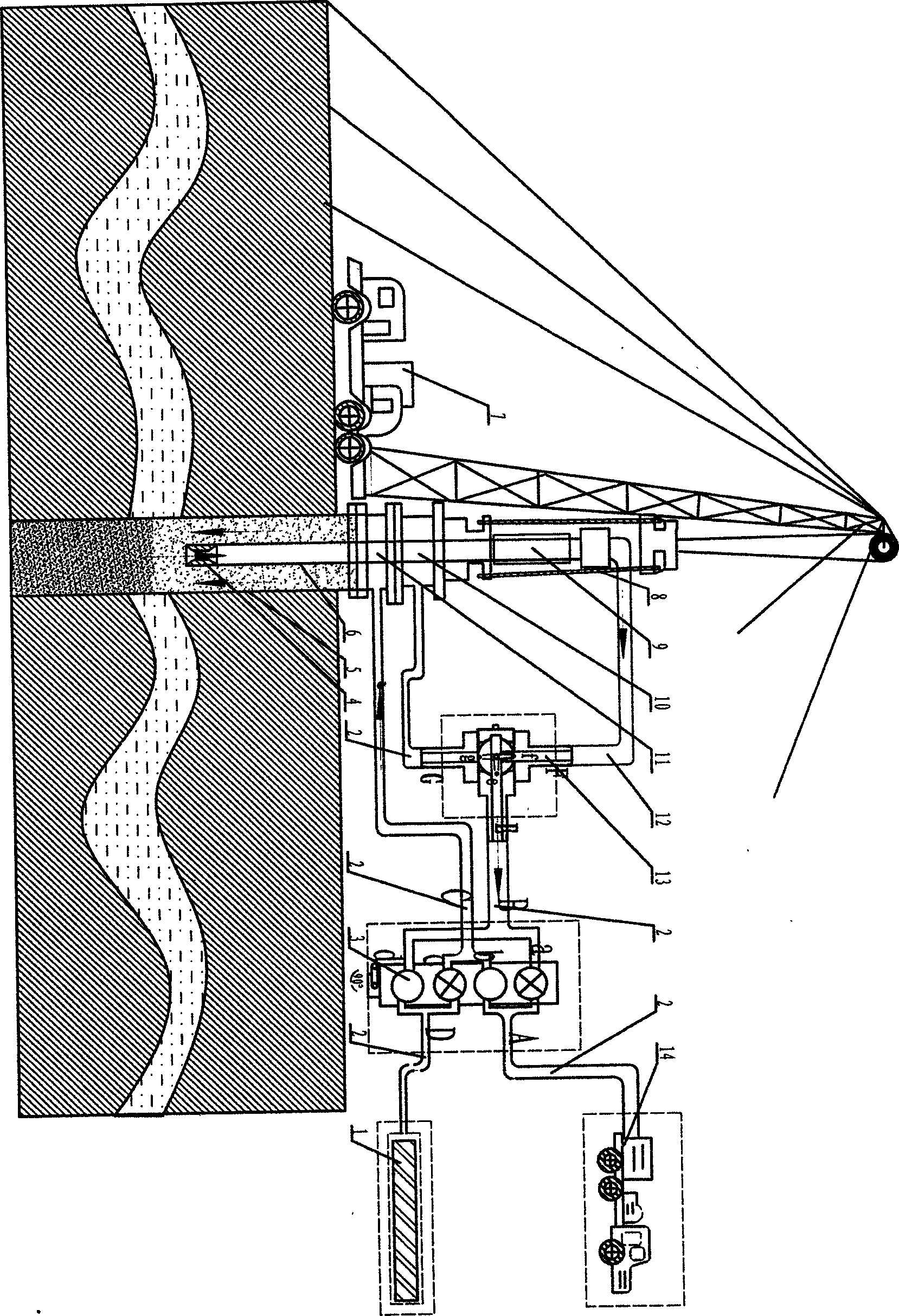

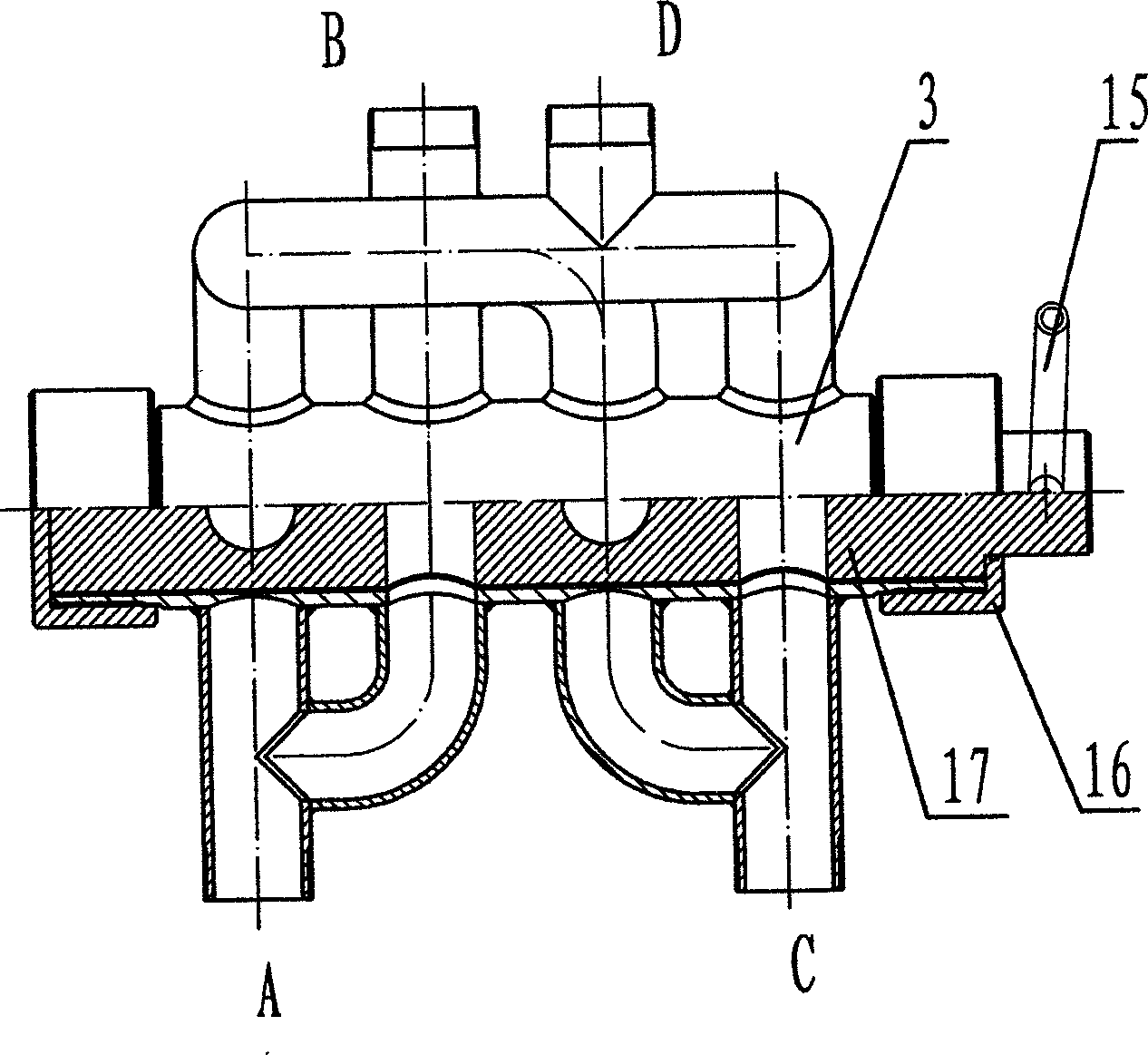

The invention relates to a continuous positive and negative sand washing device for an oil-water well, in particular to a continuous positive and negative integrated sand washing device for an oil well. The device consists of an operation machine, pipelines, a sand washing pipe, an elevator, a pump truck and the like, wherein a self-sealing wellhead is arranged at the upper end of a big four-way joint of the wellhead; the lower end of a sand washing pipe column is provided with a sand washer, and the upper end of the sand washing pipe column is provided with a reversing valve; the sand washing pipe column enters a well casing under the well through the self-sealing wellhead and the big four-way joint; a three-way valve is connected with a water hose and the self-sealing wellhead and is connected with a positive and negative sand washing regulation and control valve bank; the positive and negative sand washing regulation and control valve bank is in threaded connection with the pipelines respectively connected onto the pump truck, a foul solution cylinder, the three-way valve and the big four-way joint; the three-way valve realizes continuous sand washing operation in the process of carrying out continuous single-length sand washing and carrying out subsequent single-length sand washing by cooperation of the opening and closing of pairs of pipe lines with the reversing valve and the self-sealing wellhead; and the positive and negative sand washing regulation and control valve bank completes conversion by adjusting and aligning with four holes which are vertical in pairs on a valve core and eight holes on a valve body, so that the positive and negative continuous sand washing operation is realized.

Owner:PANJIN GUANGTUO PETROLEUM TECH

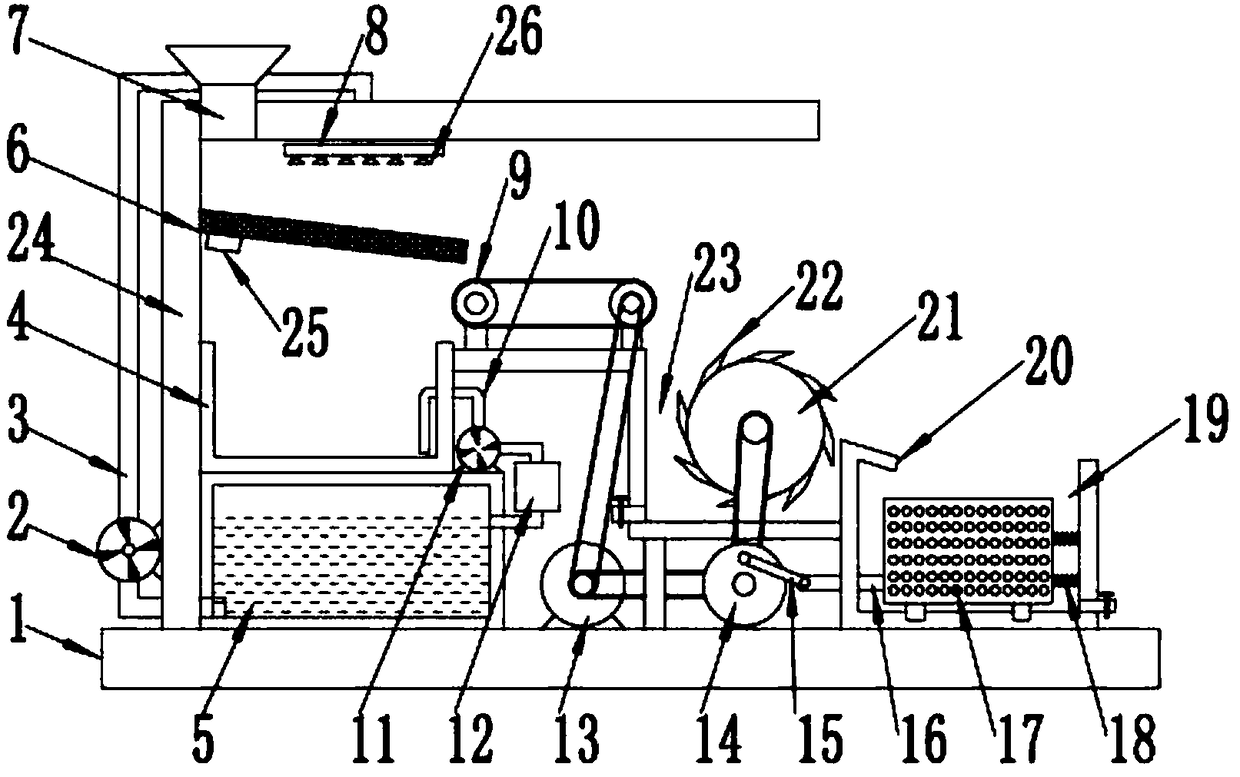

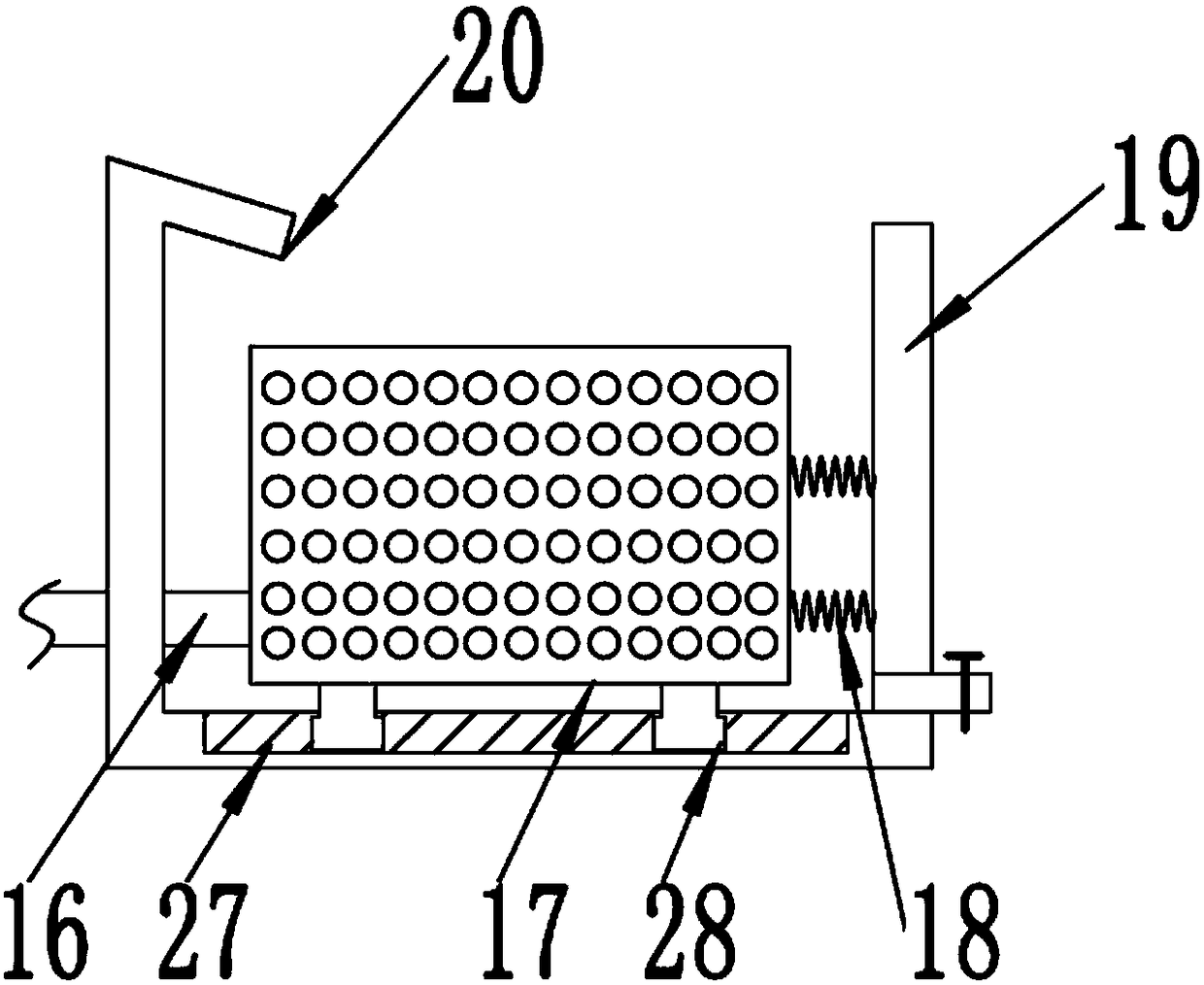

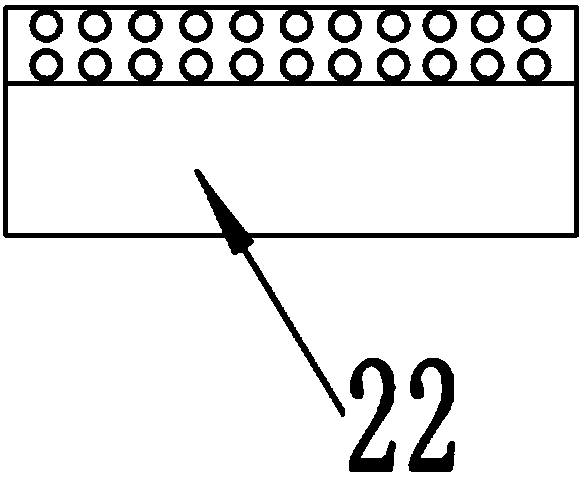

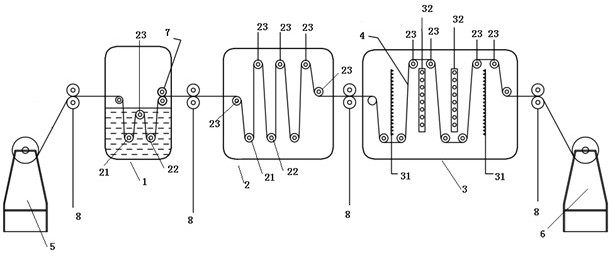

Water-saving type petroleum geology logging and sand-washing device

The invention discloses a water-saving type petroleum geology logging and sand-washing device, which comprises a base, a water tank, a sieve plate, a conveyor belt, a first cleaning tank, a second cleaning tank and a support. A feed hopper is arranged on the upper end of the support; the sieve plate is arranged on the lower end of the feed hopper; the water tank is arranged on the inner side of the support; a water holding tank is arranged on the upper end of the water tank; the conveyor belt is arranged on the right side of the sieve plate; the first cleaning tank is arranged on the right side of the conveyor belt; a rolling wheel is arranged in the first cleaning tank; the second cleaning tank is arranged on the right side of the first cleaning tank; a sliding rail is arranged on the bottom part of the second cleaning tank; a sliding block is slidably connected into the sliding rail; and the upper end of the sliding block is fixedly connected with a cleaning barrel. Through setting amulti-stage sand-washing process, a favorable sand washing effect is achieved, an automation degree is high, the manpower is reduced, meanwhile, the problem that real cuttings run away due to an improper manual sand-washing method is solved, a water resource is recycled so as to be saved, and the practicability is high.

Owner:长沙德科投资管理咨询有限公司

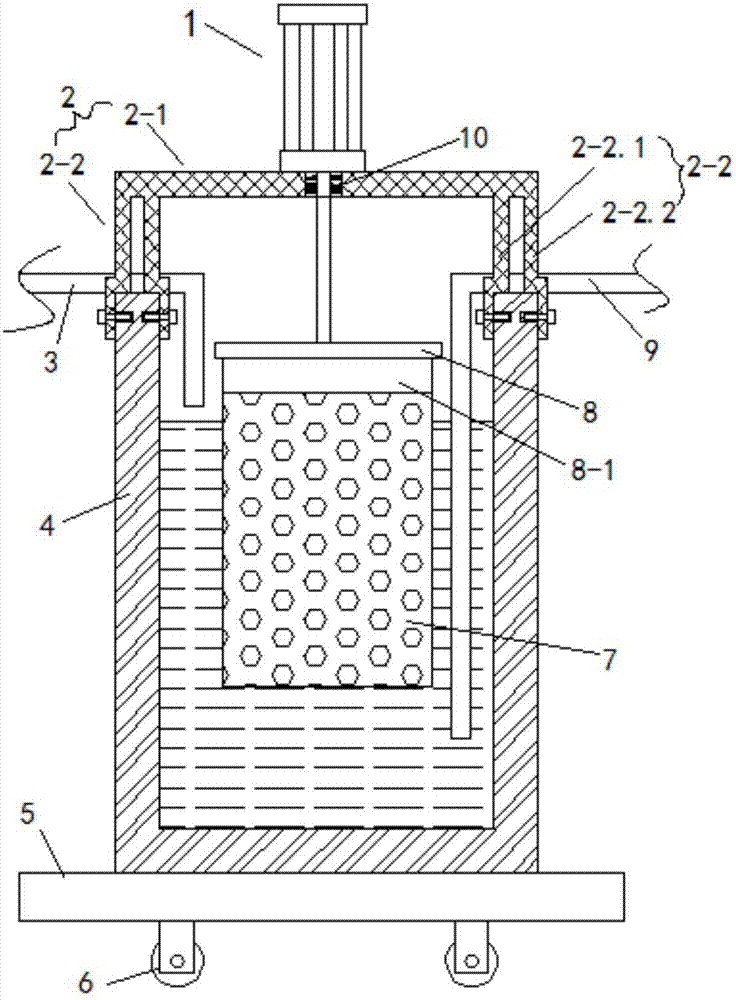

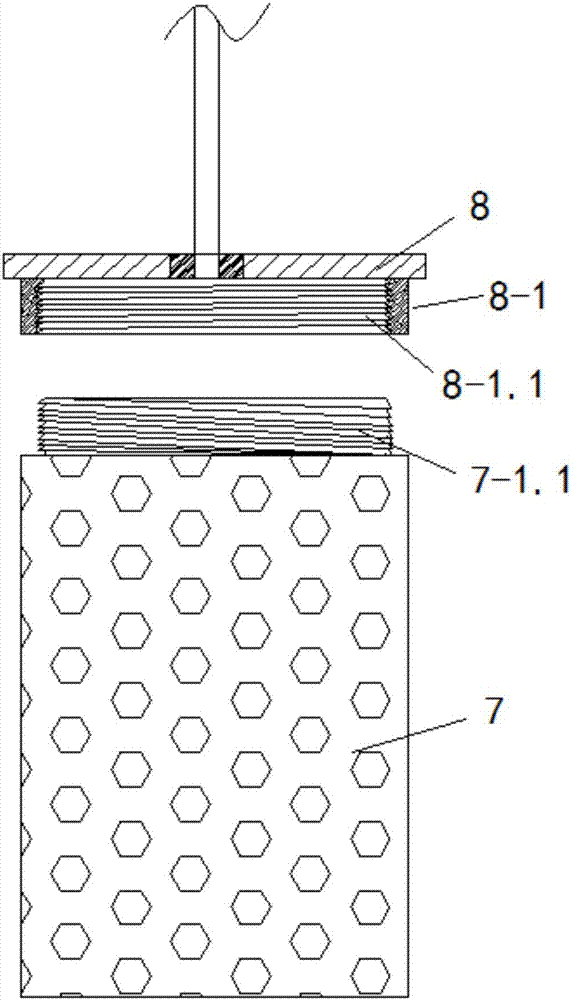

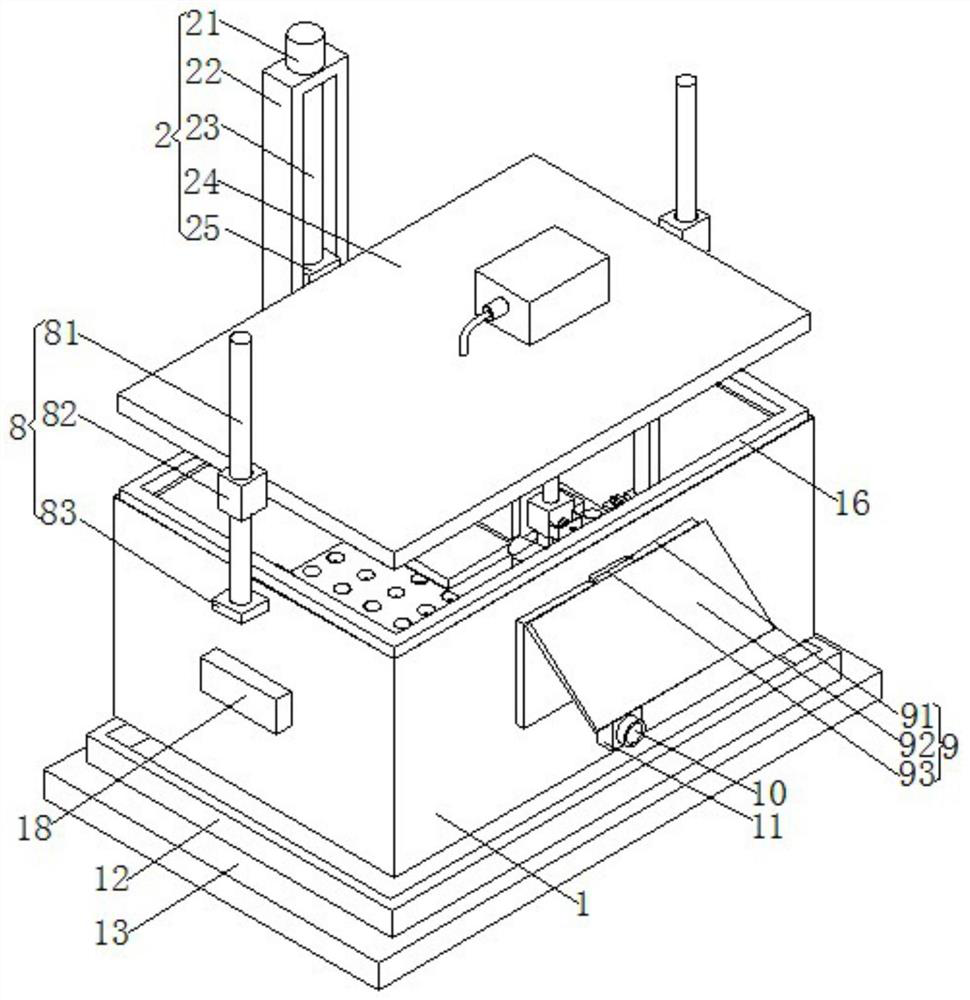

Sand washing device for geological logging

The invention discloses a sand washing device for geological logging and relates to the technical field of oil field logging equipment. The device comprises a mounting base, a sand washing pool whichis arranged on the mounting base and a sand washing tank which is located in the sand washing pool, a cover plate is fixedly arranged on the sand washing pool, and a fixing base is detachably connected onto the cover plate; a driving component is arranged on the fixing base, a transmission rod is connected to the driving component, and one end of the transmission rod is fixedly connected with theoutput end of the driving component; the other end of the transmission rod penetrates through the fixing base and is rotatably connected with the cover plate and the bottom of the sand washing pool, the transmission rod penetrates through the sand washing tank and is fixedly connected with the top and the bottom of the sand washing tank respectively, and a bearing plate is fixedly arranged on thetransmission rod; the bearing plate is fixedly connected with the bottom of the sand washing tank, and strengthening connection plates which are used for strengthening and supporting the bearing plateare fixedly connected with the tail end of the transmission rod. According to the sand washing device, the driving component drives the sand washing tank to rotate in the sand washing pool which contains clear water, so that rock debris in the sand washing tank is separated from slurry mixtures, the aim of sand washing is achieved, and the effect of sand washing is ideal.

Owner:成都捷科菲友信息技术有限公司

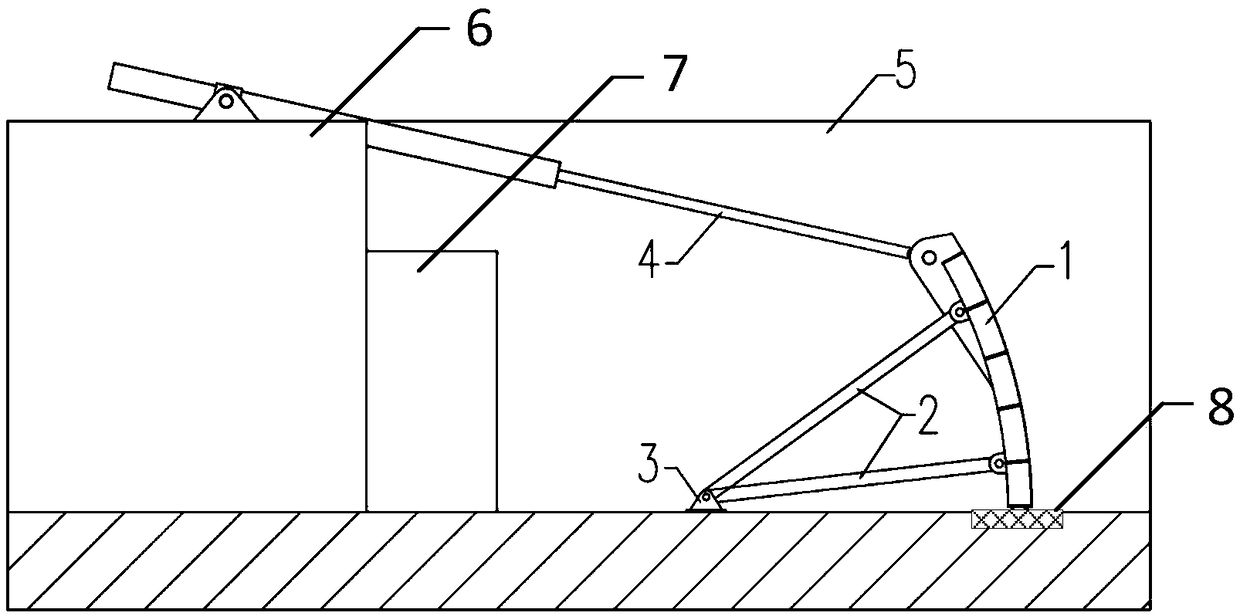

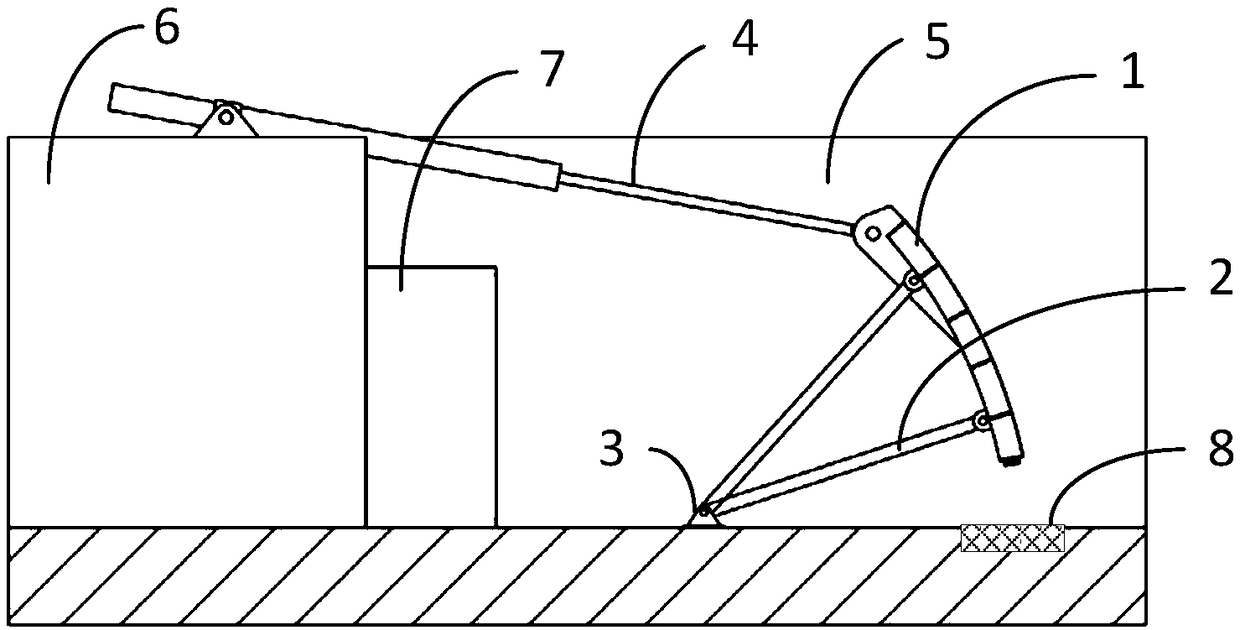

Integral horizontal rotary dam

PendingCN110409380ASimple structureMeet width requirementsBarrages/weirsHydraulic cylinderLeaking water

The embodiment of the invention discloses an integral horizontal rotary dam and relates to the field of water conservancy projects. The integral horizontal rotary dam comprises a retaining dam body, aplurality of connecting rotary rods and a driving device. The retaining dam body is arranged above a dam base and stretches along the width direction of a riverway, the connecting rotary rods are arranged in a spaced manner along the width direction of the riverway, one ends of the connecting rotary rods are hinged to one side of the retaining dam body and the other ends of the connecting rotaryrods are separately hinged to a plurality of supports pre-buried on the dam base correspondingly one by one; and the driving device is connected to the retaining dam body. The integral horizontal rotary dam not only overcomes defects that a rubber dam is easy to damage and age, long in dam lifting and collapsing time, low in safety, poor in reliability, short in service life and the like, but alsosolves the problems that a hydraulic dam side stops and leaks water, a hydraulic cylinder and an oil pipe are failed easily in the riverway and are hard to overhaul and the like, and also overcomes the defects that a conventional steel dam gate is clumsy in bed shaft, unscientific in stress, poor in sand washover effect, high in cost and the like.

Owner:李正方

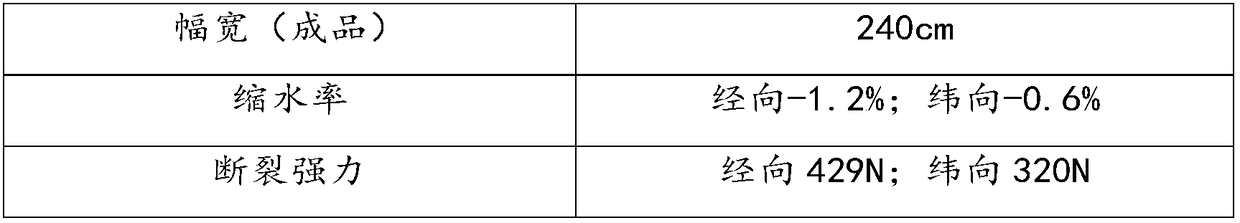

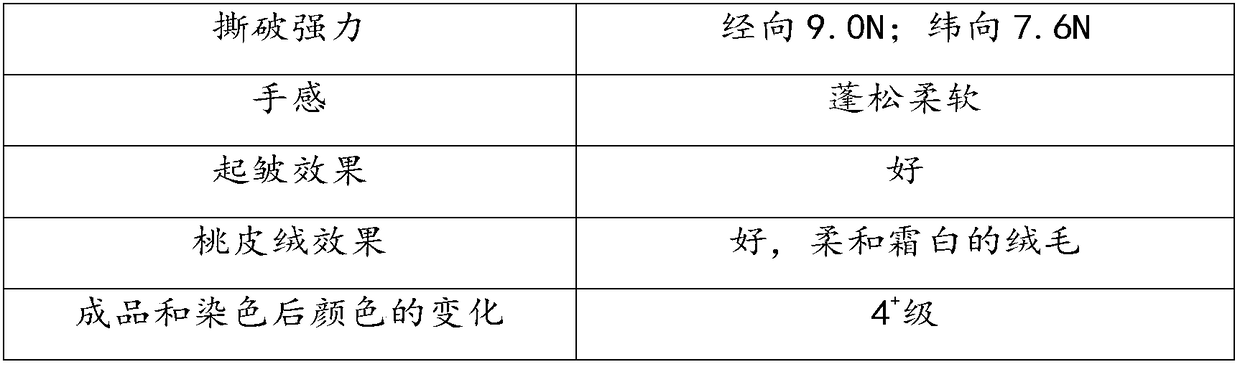

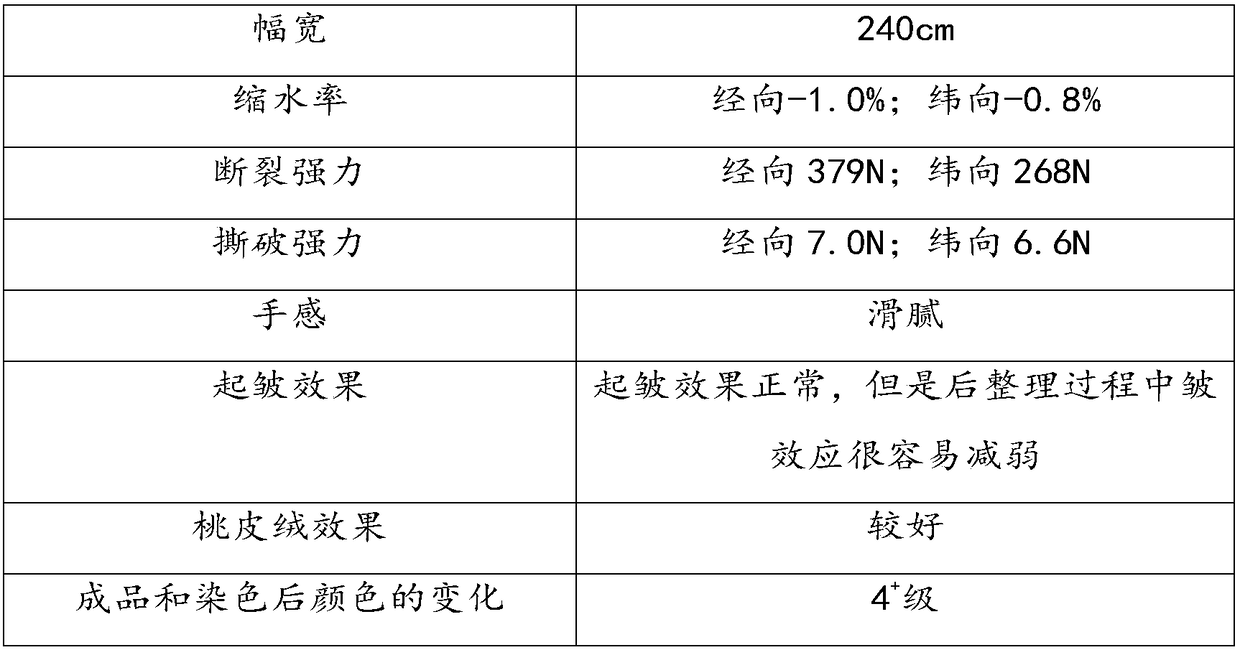

Method and application of dyeing and finishing of pure cotton fabrics

ActiveCN108642922ALower pHReduce sheddingDry-cleaning apparatus for textilesGrip property fibresSodium bicarbonateSodium metasilicate

The invention belongs to the technical field of dyeing and finishing of fabrics and relates to a method and application of dyeing and finishing of pure cotton fabrics. The cotton fabric dyeing and finishing method comprises pretreatment, dyeing and post-treatment. The dye used in the dyeing process is an s-triazine-type reactive dye. The post-treatment process orderly comprises sand washing, waterwashing, softening treatment, dehydration and drying. In the sand washing process, a mixture of sodium metasilicate and sodium bicarbonate is used as a sand washing aid, the sand washing operation iscarried out at 95-100 DEG C for 15-25 DEG C, the fabric is cooled to 35-45 DEG C and then is subjected to sand washing for 30-50min, the washing solution is discharged and the fabric is washed by water. The softening treatment process utilizes a softening agent comprising a mixture of polyurethane and epoxy modified silicone resin. The method can improve the production efficiency, reduce the generation of the defective cloth, can also produce soft and fluffy peach skin fuzzy feeling on the cloth surface, and has a natural wrinkle and antique effect.

Owner:新乡橄榄枝纺织化工有限公司

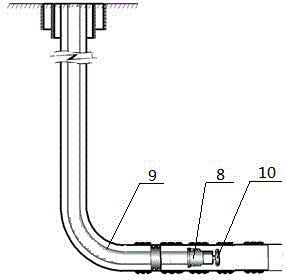

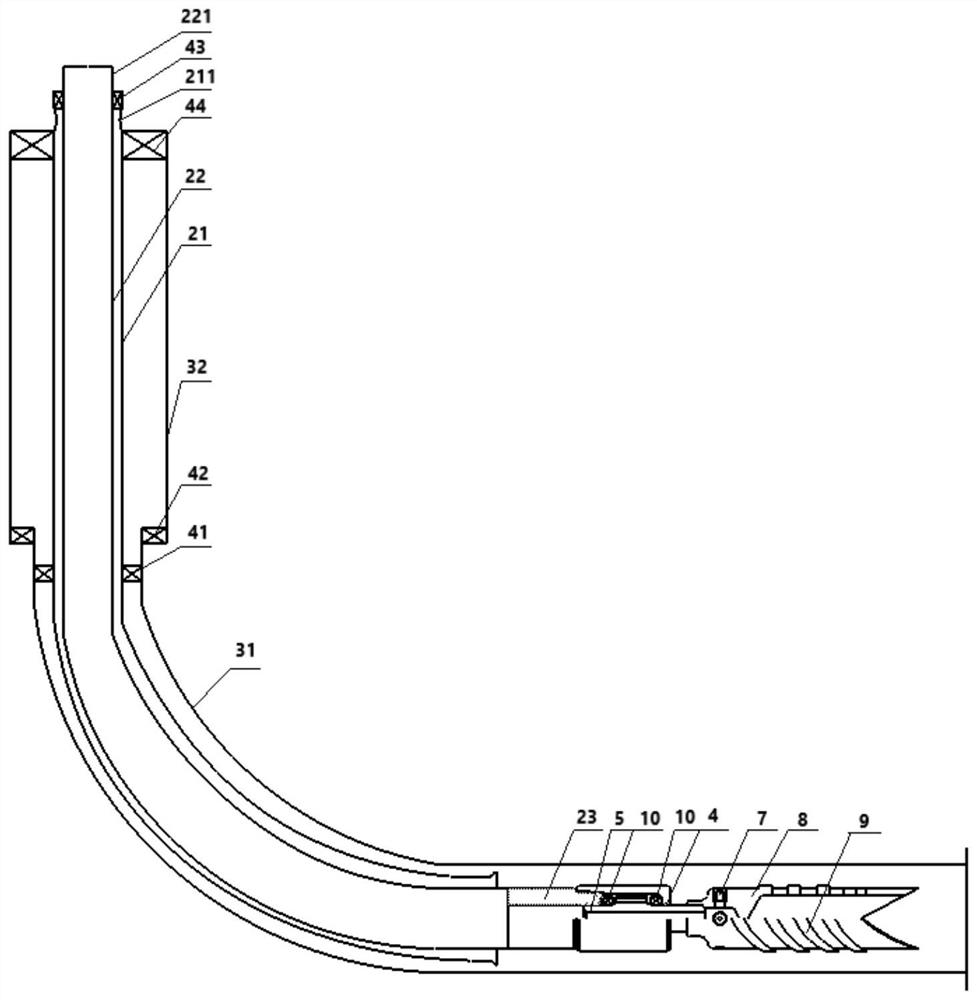

Rotational flow sand washing process pipe column

PendingCN112459735AIncrease flushing powerImprove sand washing efficiencyDrilling rodsFlushingHydrologyMechanical engineering

The embodiment of the invention discloses a sand washing pipe column and a sand washing method, the sand washing pipe column comprises a liquid flow reverser and a cyclone, and the lower end of the liquid flow reverser is connected with the cyclone. A descending channel for sand washing liquid to pass through and an ascending channel for returned liquid to pass through are formed in the liquid flow reverser. The upper part of the descending channel is communicated with an external space through a first opening in the side surface of the liquid flow reverser, and the lower part of the descending channel is communicated with a flow channel in the cyclone. An opening is formed in the lower part of the ascending channel. The cyclone is configured to convert the sand washing liquid flowing outof the descending channel from linear flow into rotational flow. The liquid flow reverser further comprises a blocking device, and the blocking device is located on the outer side of the sand washingpipe column and arranged to divide an annular space between sleeves into which the sand washing pipe column descends into an upper space and a lower space. The upper space is communicated with the descending channel.

Owner:CHINA OILFIELD SERVICES

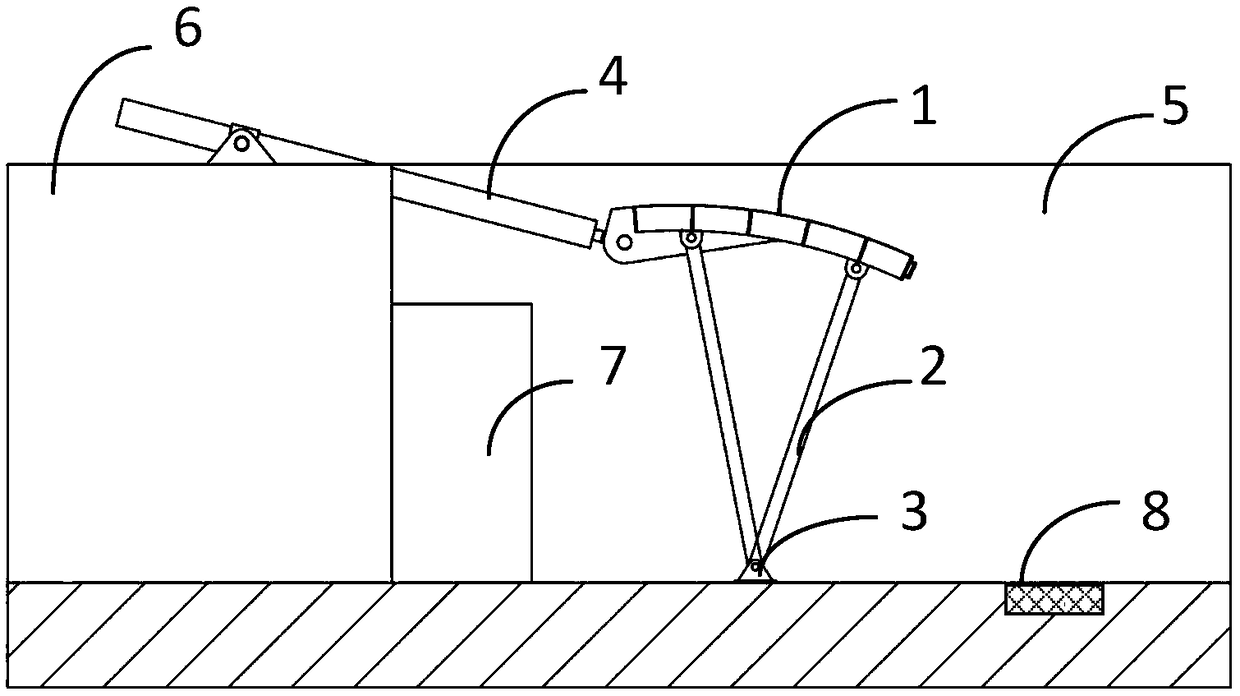

Integral horizontal rotary dam

PendingCN110777742ASimple structureMeet width requirementsBarrages/weirsHydraulic cylinderRiver routing

The embodiment of the invention discloses an integral horizontal rotary dam, and relates to the field of water conservancy projects. The integral horizontal rotary dam comprises a retaining dam body,at least two fixing piers and a dam body driving device, wherein the retaining dam body is arranged above a dam foundation and extends in the width direction of a river channel; the fixing piers are arranged on one side of the dam body at intervals along the width direction of the river channel and are connected with the dam foundation; and each fixing pier is hinged to one side of the dam body through a hinge device. According to the integral horizontal rotary dam, the defects that a rubber dam is easy to damage and age, the time for dam lifting and collapsing is long, the safety is low, thereliability is poor, the service life is short and the like can be overcome; furthermore, the problems that leakage occurs among side water-block rubber of a hydraulic dam, hydraulic cylinders and oilpipes are prone to failure in the river channel, the overhaul is difficult and the like can be solved; and meanwhile, the problems that a bottom shaft of a traditional steel dam gate is rough, not scientific in stress bearing, poor in sand punching effect and high in manufacturing cost and the like can be overcome.

Owner:李正方

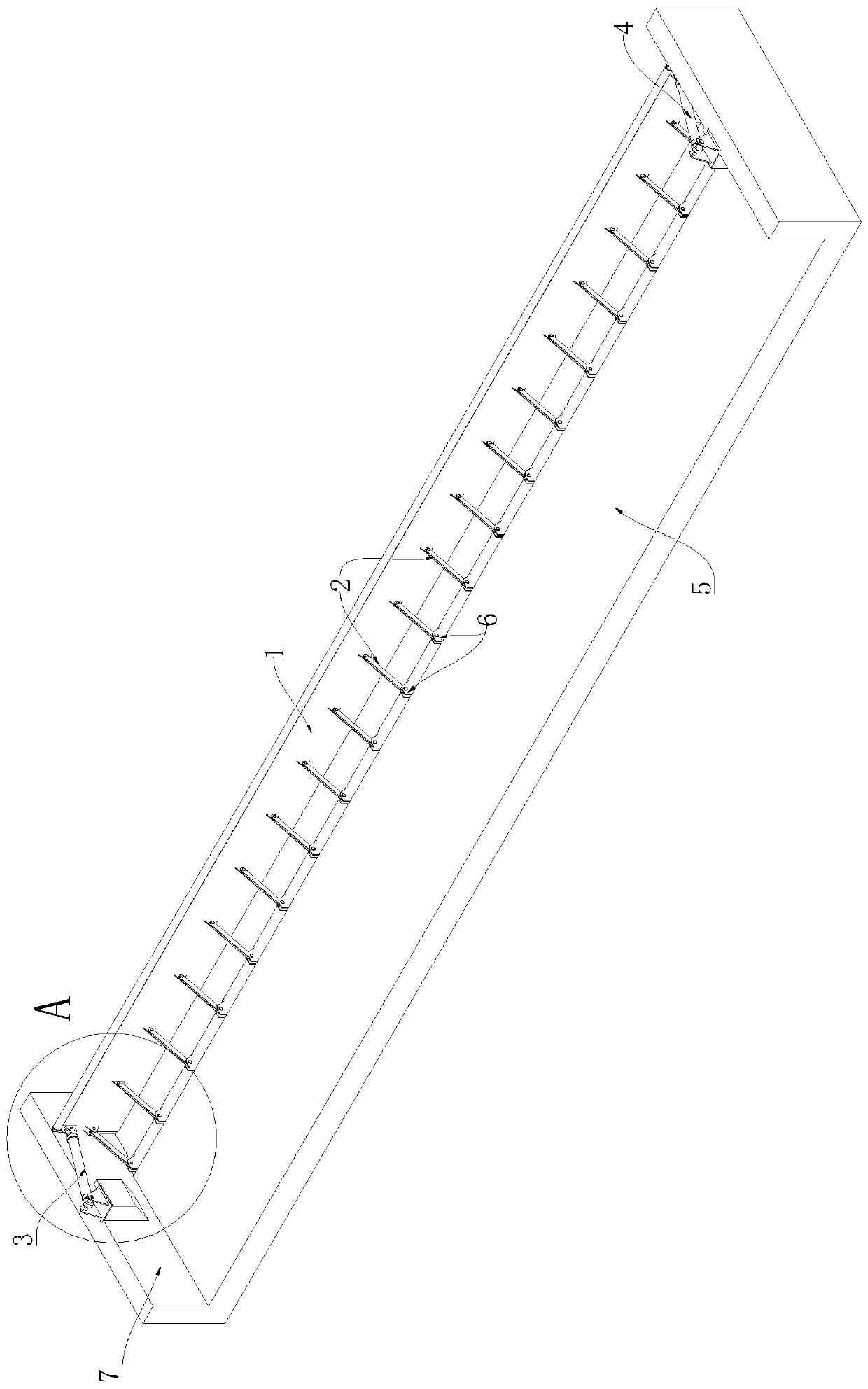

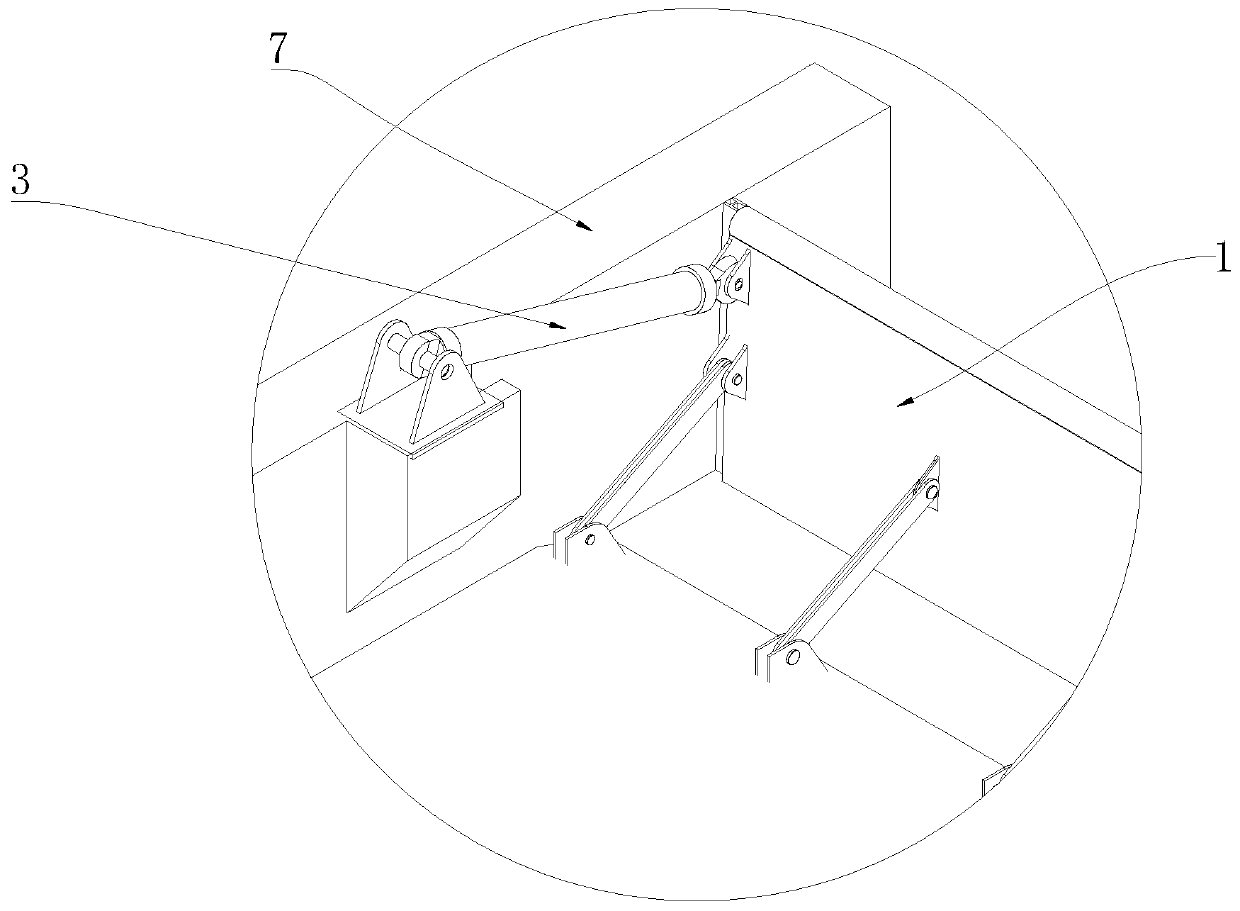

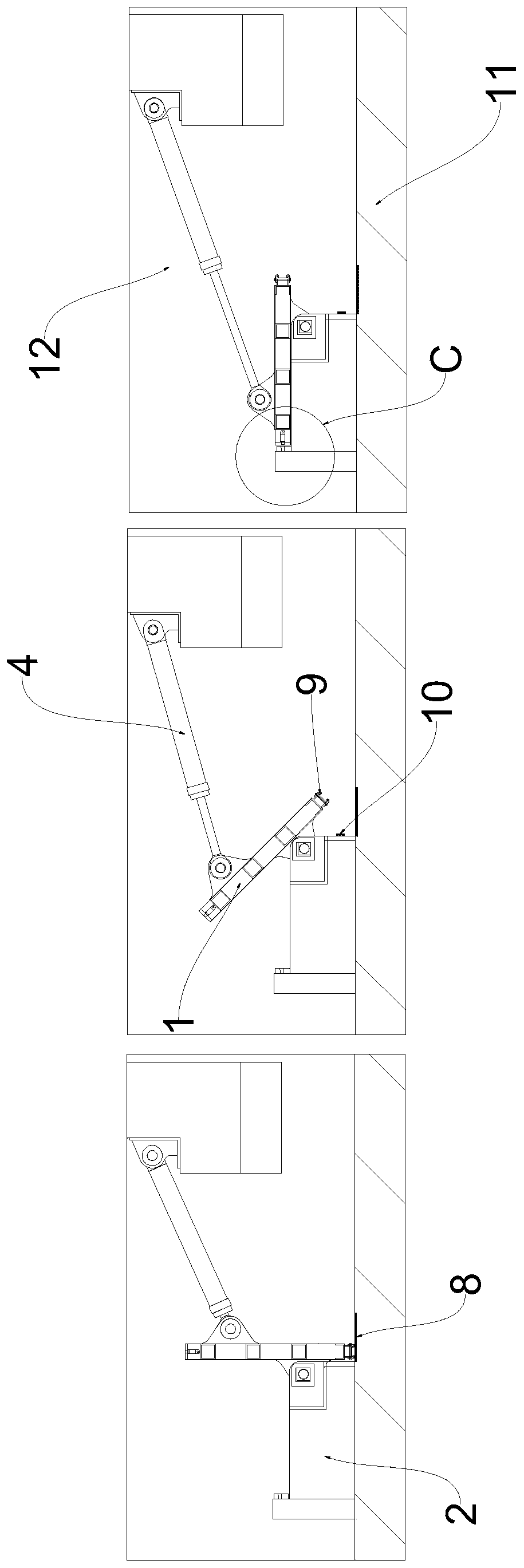

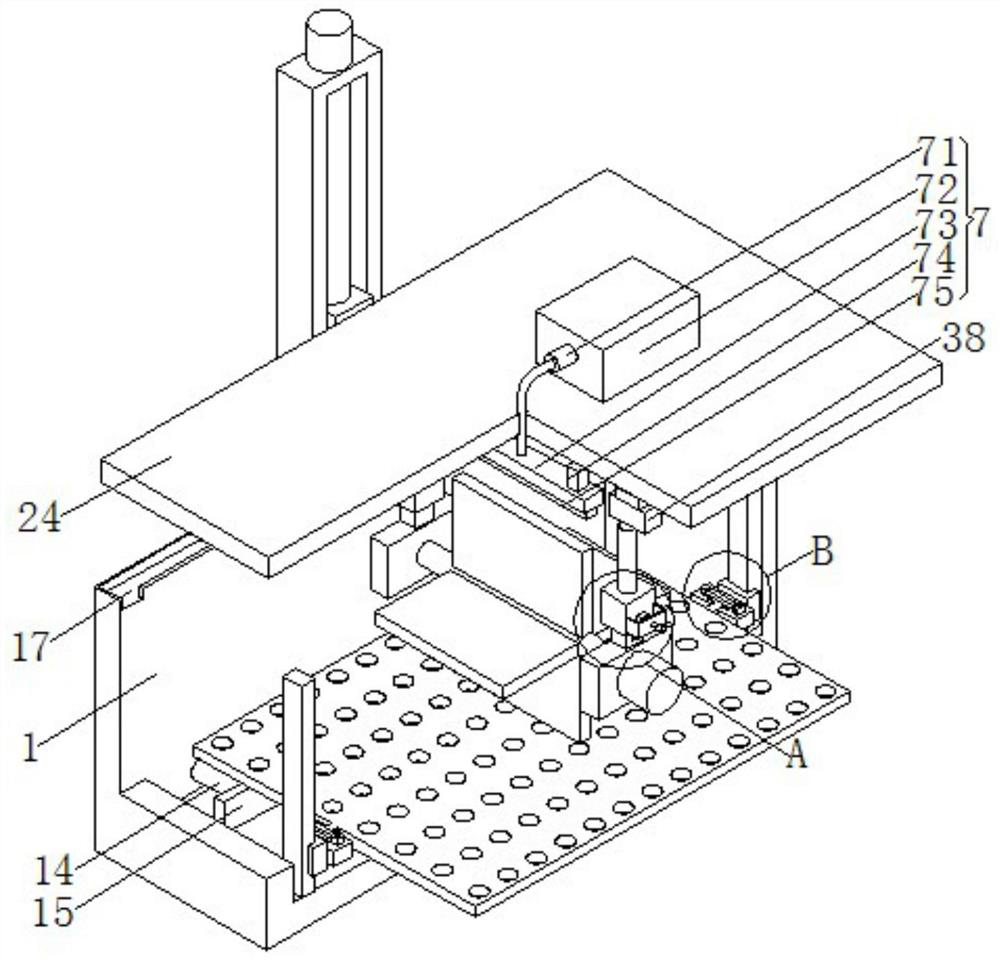

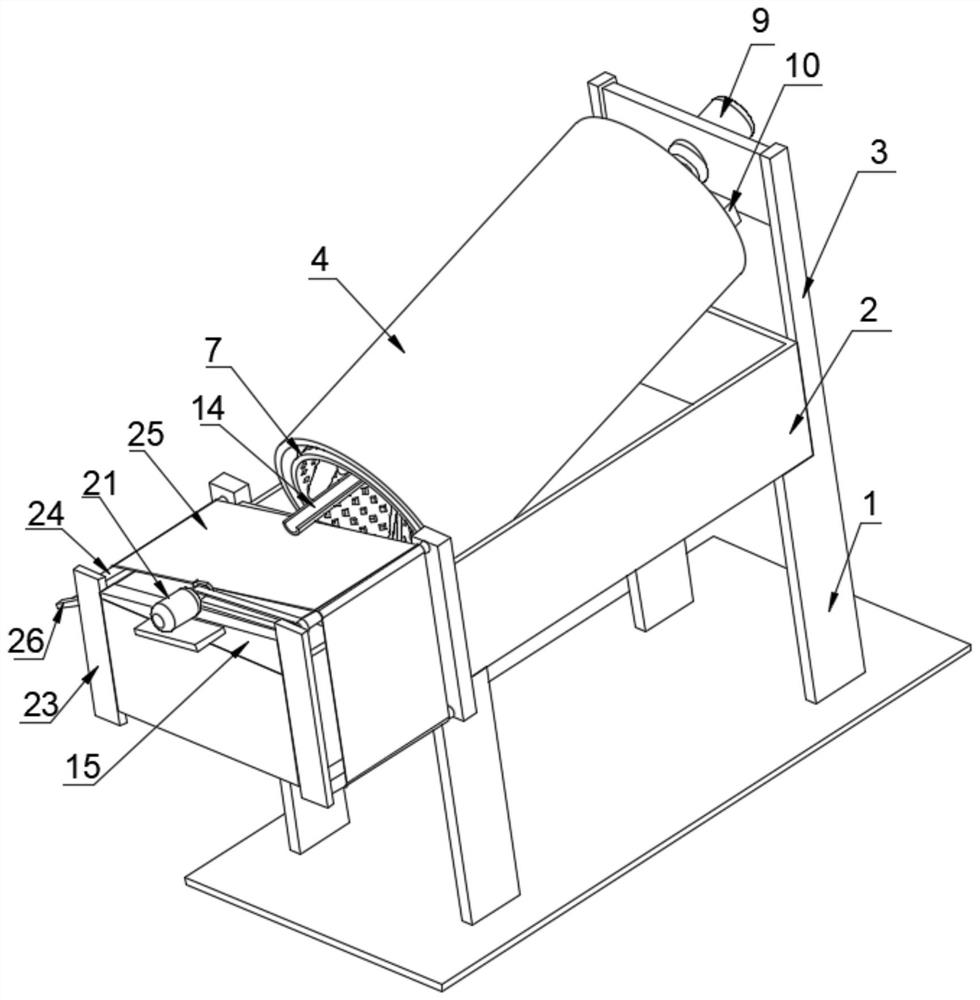

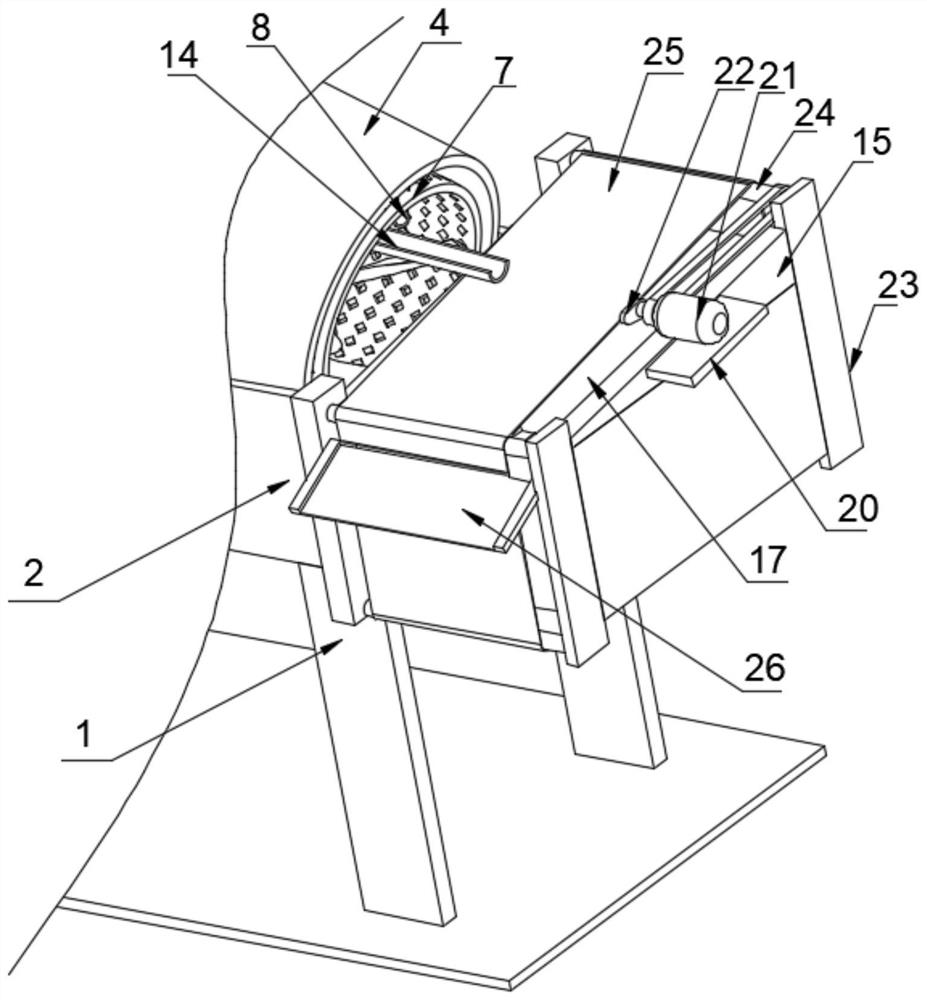

Vertical sand-washing device for logging

The invention discloses a vertical sand-washing device for logging and relates to the technical field of oilfield logging equipment. The vertical sand-washing device for logging comprises a base, a sand-washing pool arranged on the base and a sand-washing tank located in the sand-washing pool; a high mounting plate is detachably connected to an opening of the sand-washing pool and provided with alifting drive assembly; and the output end of the lifting drive assembly penetrates through the high mounting plate to extend into the sand-washing pool and is fixedly connected with the sand-washingtank. The sand-washing tank is driven by the lifting drive assembly to vibrate up and down in the sand-washing pool with clean water in a reciprocating mode, then rock debriss and a slurry mixture inthe sand-washing tank are separated so that the purpose of sand washing can be achieved, and the sand washing effect is ideal.

Owner:成都捷科菲友信息技术有限公司

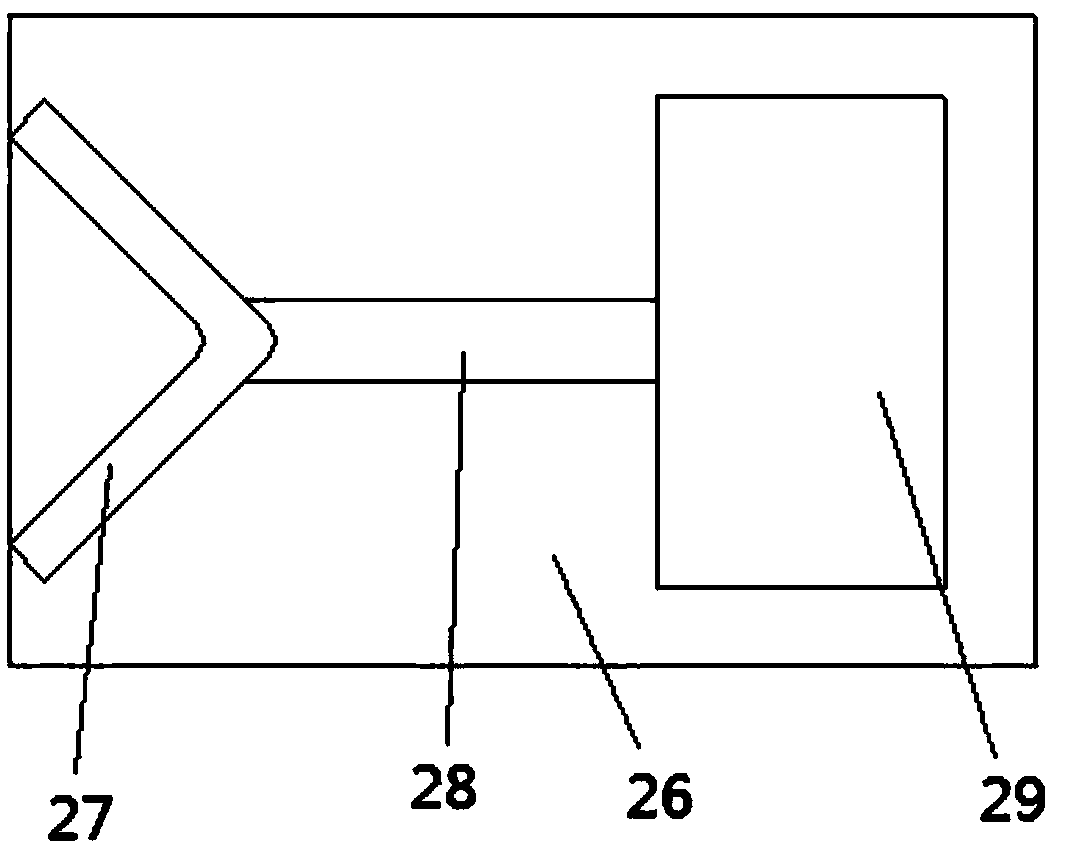

Sand washing machine with automatic feeding function

InactiveCN108405170AGood initial purification effectImprove feeding efficiencyWet separationEngineeringMechanical engineering

The invention discloses a sand washing machine with an automatic feeding function. The sand washing machine with the automatic feeding function comprises a sand washing tank. The two sides of the sandwashing tank are connected with moving platforms, a plurality of sliding guide rails which are arranged in parallel are arranged on the side walls of the moving platforms, and guide rail sliding strips which are matched with the sliding guide rails are arranged on the side wall of the sand washing tank. A fixed support is arranged on the outer side of the sand washing tank, a movable support is arranged on the fixed support, and an electric-hydraulic push rod which is connected with the movable support is arranged on the fixed support. A sand entering plate is connected with the sand enteringend of the sand washing tank and connected with a feeding device. The feeding device comprises an outer barrel. An inner barrel is arranged in the outer barrel in a sleeved mode, a lifting device isarranged at the bottom of the inner barrel and connected with a lifting plate, and the lifting plate is connected with a conical platform through a rotating platform. A plurality of through holes areuniformly distributed in the side wall of the inner barrel, a mounting platform is arranged on one side of the outer barrel, and a V-shaped baffle is arranged on the mounting platform. A barrel body of the inner barrel is higher than a barrel body of the outer barrel. The sand washing machine with the automatic feeding function has the advantages of being high in feeding efficiency and good in sand washing effect.

Owner:湖州众创小微创业园企业管理股份有限公司

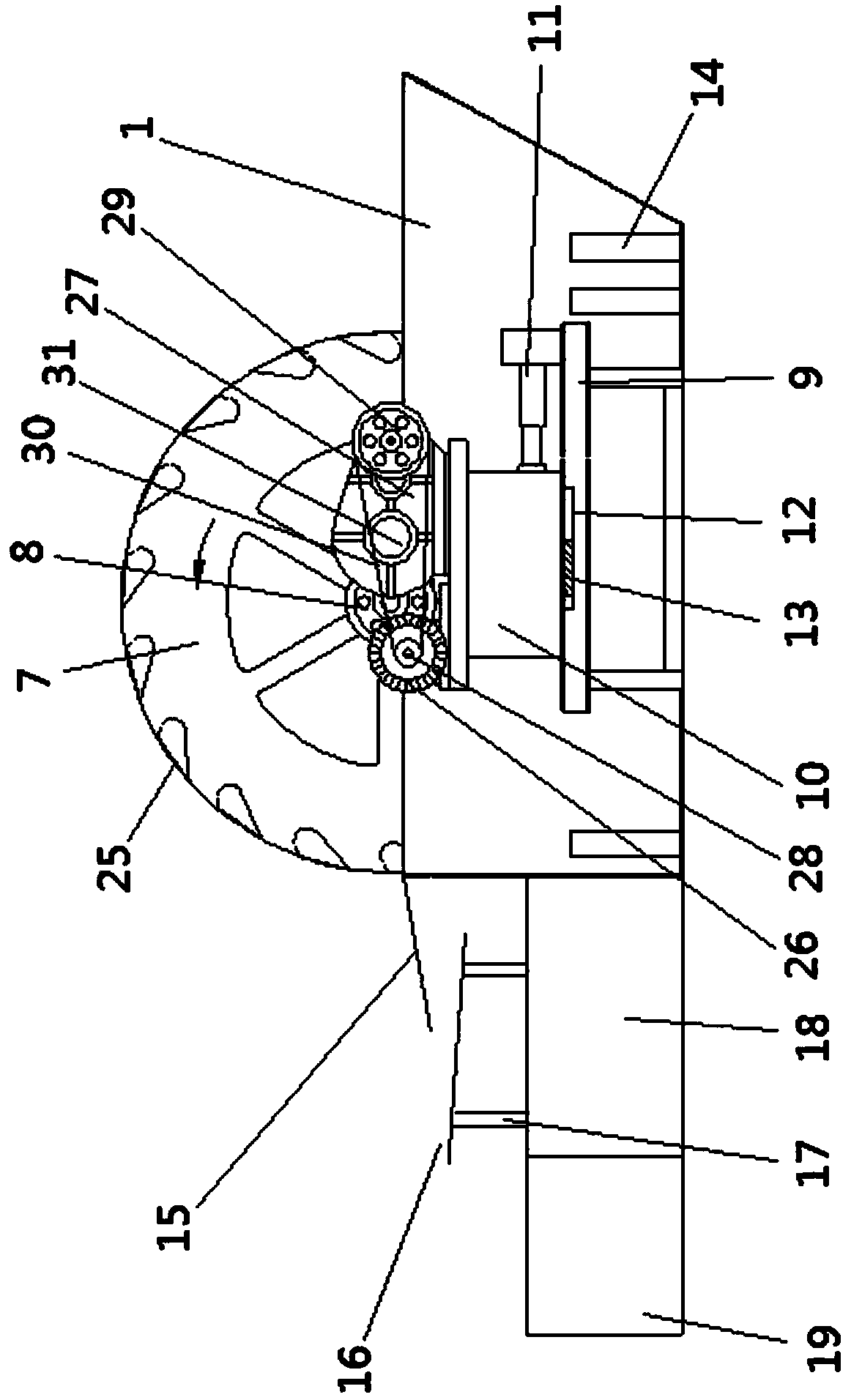

A cloth sand washing device

ActiveCN110872749BReduce workloadRealize mechanized operationTextile treatment containersTextile treatment carriersCrankGear wheel

The invention discloses a cloth sand washing device, belonging to the field of textile production machinery. The cloth feeding support table; the sand washing box is provided with a cloth feeding walking mechanism, which includes two rack tracks arranged on the main support table, and transfer gears are meshed on the two rack tracks. The middle connecting rod and the lifting rod constitute a crank-slider mechanism; the cloth feeding support table is provided with a lower groove, and the bottom of the lower groove is provided with a drop hole that matches the winding shaft of the cloth roll, and a slide rail is connected below the drop hole The cavity, the cavity of the slide rail is gradually lowered from the side of the cloth feeding support table to the side of the cloth rolling support table. The invention can realize the mechanized operation of the shuttle of the cloth head end, can avoid the cloth wrinkle, is beneficial to improve the sand washing effect of the cloth, and also does not need to manually transfer the winding shaft from the side where the cloth feeding support table is located to the side where the cloth rolling support table is located. Greatly reduces the workload of related personnel.

Owner:禹旦

Fabric sand washing device for underwear production

InactiveCN112301595AReduce gapPrevent overflowTextile treatment containersTextile treatment machine arrangementsElectric machineryStructural engineering

The invention discloses a fabric sand washing device for underwear production. The fabric sand washing device comprises a shell, a lifting unit, a mixing unit, a discharging pipe and an electromagnetic valve. The discharging pipe is arranged at the bottom end of the front side face of the shell, the electromagnetic valve is arranged on the outer side of the discharging pipe, a filtering unit is arranged in the shell, stabilizing units are arranged on the left side face and the right side face of the shell correspondingly, and an observing unit is arranged at the top end of the front side faceof the shell; the lifting unit comprises a main motor, a mounting block, a lead screw, a shell cover and a movable block, the mounting block is arranged on the rear side face of the shell, the lead screw is rotatably connected into a groove in the front side face of the mounting block, the main motor is arranged at the top end of the mounting block, and an output shaft of the main motor is connected with the top end of the lead screw; and the movable block is slidably connected with the groove in the front side face of the mounting block, and a screw hole in the side face of the movable blockis in threaded connection with the lead screw. The fabric sand washing device for underwear production is simple to use, convenient to take, high in practicality and good in mixing effect.

Owner:温州盛阳服装有限公司

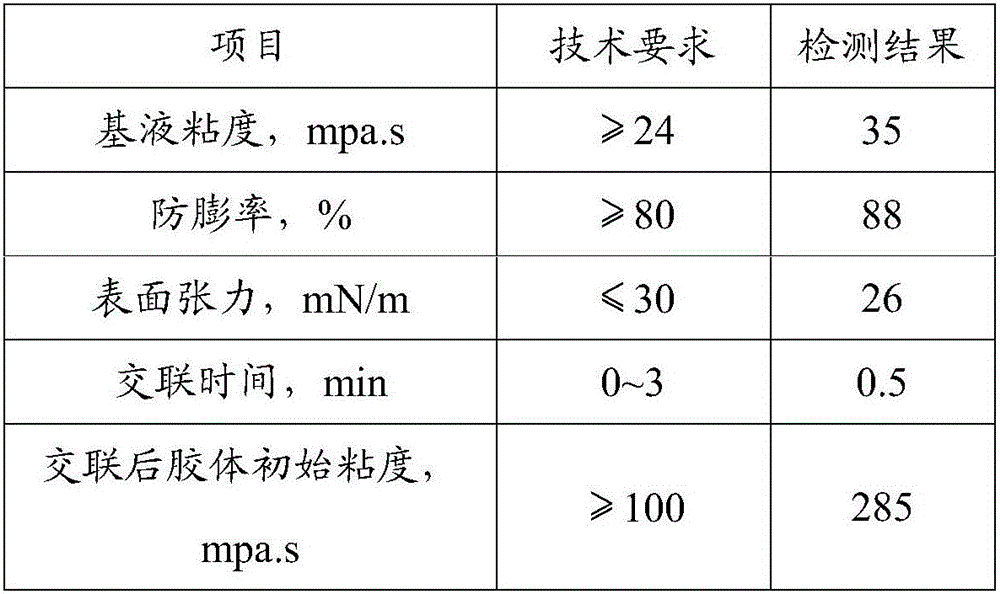

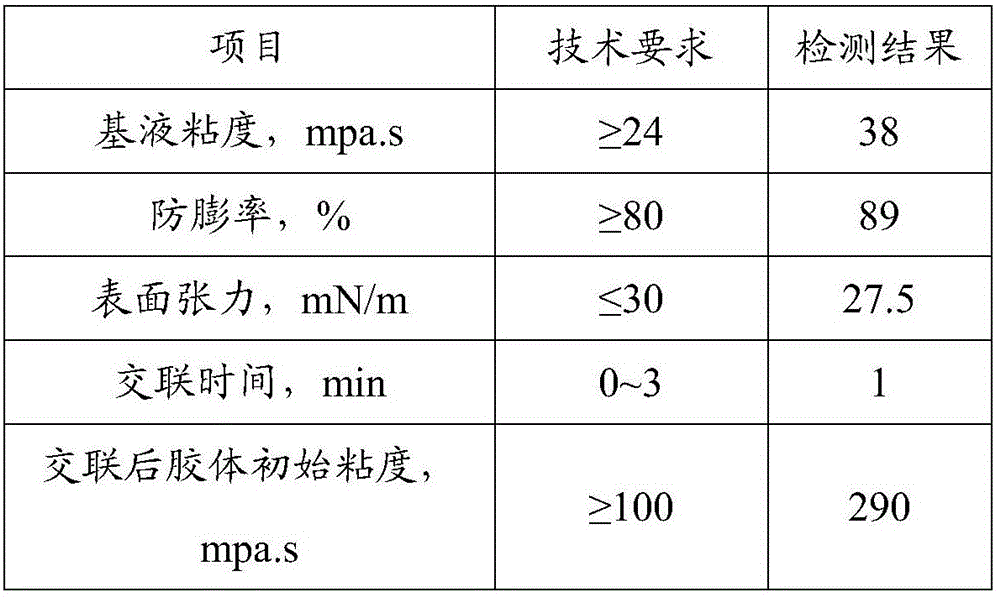

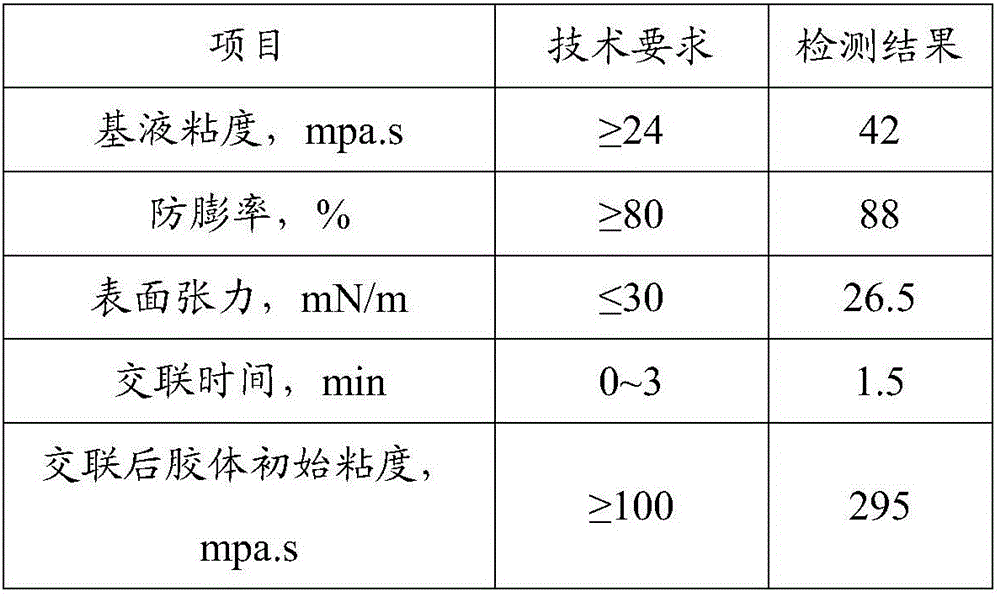

Cross-linkable polymer linear colloid system for shale gas fracturing and preparation method thereof

InactiveCN106479474AHigh viscosityGood sand washing effectDrilling compositionPolymer scienceDissolution

The invention discloses a cross-linkable polymer linear colloid system for shale gas fracturing and a preparation method thereof. Through being metered in parts by weight, the polymer linear colloid system comprises 0.3 to 0.5 part of thickening agents, 0.3 to 0.5 part of clay stabilizing agents, 0.3 to 0.5 part of discharge aiding agents, 0.2 to 0.3 part of crosslinking agents and 98.2 to 98.9 parts of flowback fluid. The preparation method comprises the steps of base solution preparation and mixing; the flowback fluid according to the formula ratio is taken; the thickening agents are added; stirring is performed till the dissolution; then, the clay stabilizing agents and the discharge aiding agents according to the formula ratio are added; the mixture is uniformly mixed to prepare base liquid for use; during the fracturing operation, the crosslinking agents in the formula ratio is added into the base liquid; the polymer linear colloid system is obtained. Compared with a low-concentration guar gum system with wide application in the prior art, the linear colloid base liquid prepared in the flowback fluid has the characteristics of high viscosity, crosslinking performance, low friction resistance and good sand washing replacing effect, and has good application prospects.

Owner:SICHUAN WELDON CHEM

Continuous positive and negative integrated sand washing device for oil well

ActiveCN102383750BSatisfy sand washing requirementsImprove sand washing effectFlushingOil waterEngineering

The invention relates to a continuous positive and negative sand washing device for an oil-water well, in particular to a continuous positive and negative integrated sand washing device for an oil well. The device consists of an operation machine, pipelines, a sand washing pipe, an elevator, a pump truck and the like, wherein a self-sealing wellhead is arranged at the upper end of a big four-way joint of the wellhead; the lower end of a sand washing pipe column is provided with a sand washer, and the upper end of the sand washing pipe column is provided with a reversing valve; the sand washing pipe column enters a well casing under the well through the self-sealing wellhead and the big four-way joint; a three-way valve is connected with a water hose and the self-sealing wellhead and is connected with a positive and negative sand washing regulation and control valve bank; the positive and negative sand washing regulation and control valve bank is in threaded connection with the pipelines respectively connected onto the pump truck, a foul solution cylinder, the three-way valve and the big four-way joint; the three-way valve realizes continuous sand washing operation in the process of carrying out continuous single-length sand washing and carrying out subsequent single-length sand washing by cooperation of the opening and closing of pairs of pipe lines with the reversing valve and the self-sealing wellhead; and the positive and negative sand washing regulation and control valve bank completes conversion by adjusting and aligning with four holes which are vertical in pairs on a valve core and eight holes on a valve body, so that the positive and negative continuous sand washing operation is realized.

Owner:PANJIN GUANGTUO PETROLEUM TECH

Integrated upward-spiral steel dam

The embodiment of the invention discloses an integrated upward-spiral steel dam in order to overcome the shortcomings of a rubber dam, a hydraulic dam and a steel dam gate in the prior art. Meanwhile,the integrated upward-spiral steel dam is relatively simple in overall structure, scientifically stressed, convenient to overhaul, good in sand washing effect and not limited by water quality, terrain and the width of a river way.

Owner:李正方

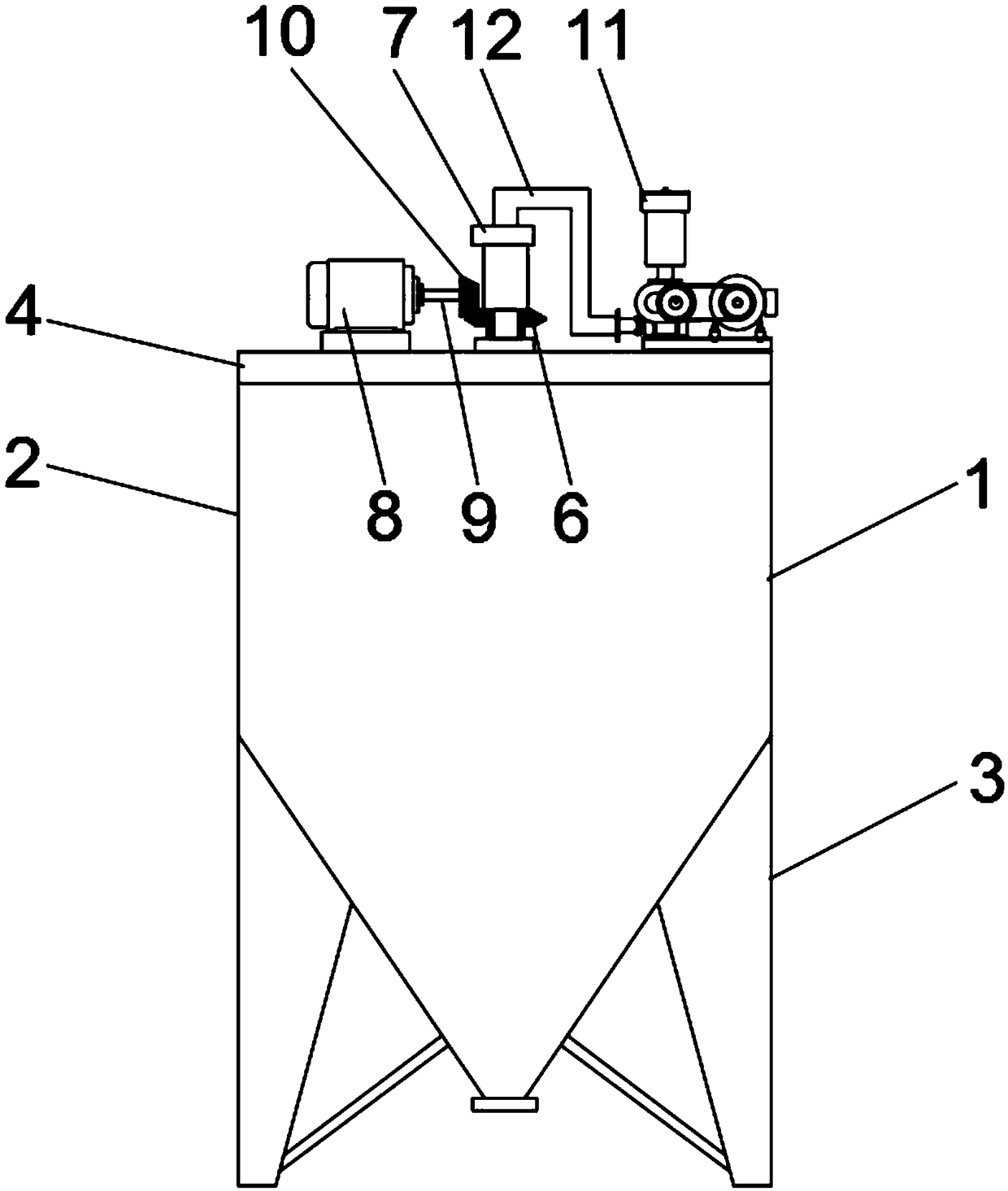

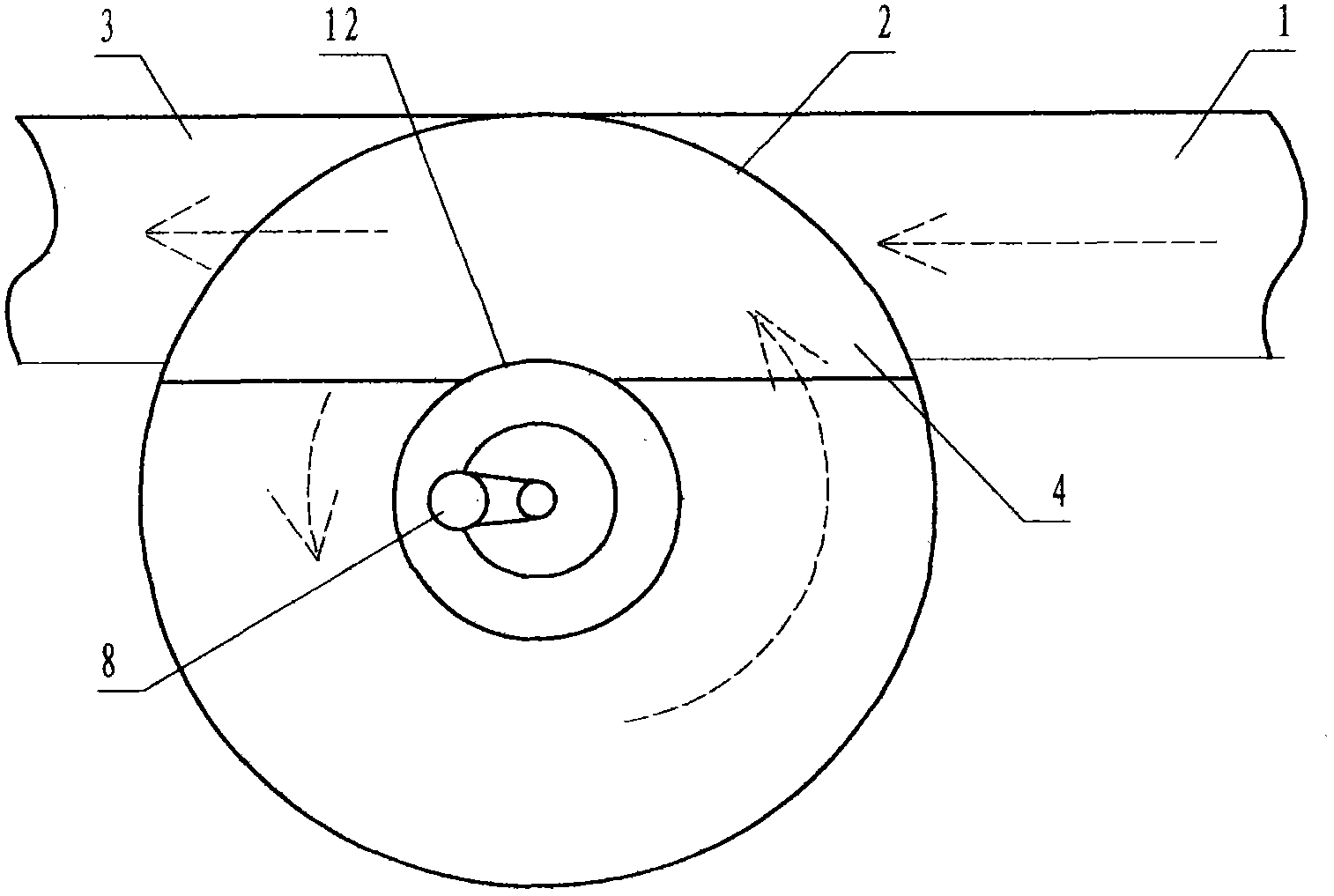

Double-barrel reverse-flow type environment-friendly sand washer with recovery function

ActiveCN113976436ATo achieve the purpose of cleaning and removing impuritiesAvoid cloggingSievingScreeningWater useWater flow

The invention discloses a double-barrel reverse-flow type environment-friendly sand washer with a recovery function, which comprises a rack, and is characterized in that the upper end of the rack is fixedly connected with a water tank, the water tank is internally and fixedly connected with a support frame, and the support frame is fixedly connected with a double-barrel assembly. The invention relates to the technical field of sand washing and screening equipment, a double-barrel assembly is arranged, a driving motor is used for driving an inner barrel and a spiral plate to rotate, at the moment, the inner barrel is matched with a flow guide plate to drive cleaning water to reversely flow upwards, the spiral plate drives sand and stones to move upwards, under the driving of the flow guide plate, the countercurrent direction of the water flow is inclined upwards, and the gravels move upwards in a spiral mode, so that differential speed is formed between the gravels and the water flow, and the purpose of cleaning and impurity removal of the gravels is achieved.

Owner:凯盛石英材料(海南)有限公司

Sand washing process for cotton fabric

InactiveCN107217473AImprove antibacterial propertiesAvoid pollutionBiochemical fibre treatmentVegetal fibresPorositySilicon dioxide

The invention discloses a sand washing process for a cotton fabric. According to the invention, calcined shell powder is used as a raw material for sand washing of the cotton fabric, so environmental pollution caused by usage of silica in conventional sand washing is avoided, and the antibacterial properties of the cotton fabric can be improved; good sand washing effect is obtained by controlling the porosity, particle size and usage amount of the shell powder during sand washing; and thus, the sand washing process provided by the invention is a novel environment-friendly fabric treating process.

Owner:景宁畲族自治县牧风工艺品厂

Dragging and restraining type sand washing pipe string for horizontal well

The invention provides a dragging and restraining type sand washing pipe string for a horizontal well. The dragging and restraining type sand washing pipe string for the horizontal well comprises a first oil pipe, a second oil pipe, an adapter pup joint, a speed governor assembly, a spray nozzle body and a turbulence sheet, wherein the first oil pipe is arranged in an oil well; a sand washing liquid return opening is formed in the outer wall of the upper end of the first oil pipe; the second oil pipe is arranged in the first oil pipe; an annular structure is formed between the second oil pipe and the first oil pipe; one end of the adapter pup joint is connected with the lower end of the second oil pipe; the speed governor assembly comprises a speed governor mandrel; one end of the speed governor mandrel is coaxially connected with the other end of the adapter pup joint; the speed governor mandrel can rotate relative to the adapter pup joint; the spray nozzle body is fixedly connected with the other end of the speed governor mandrel; a plurality of spray nozzles arranged at intervals are arranged on the spray nozzle body; the spray nozzle body can drive the speed governor mandrel to rotate; and the turbulence sheet is fixedly arranged on the periphery of the spray nozzle body and is positioned at the downstream position of the plurality of spray nozzles. The dragging and restraining type sand washing pipe string for the horizontal well provided by the embodiment of the invention has the beneficial effects that an impact damage effect can be achieved on sand at the bottom of the horizontal section of the horizontal well, and at the same time, sand-containing sand washing liquid can be brought back to the position above the horizontal section.

Owner:PETROCHINA CO LTD

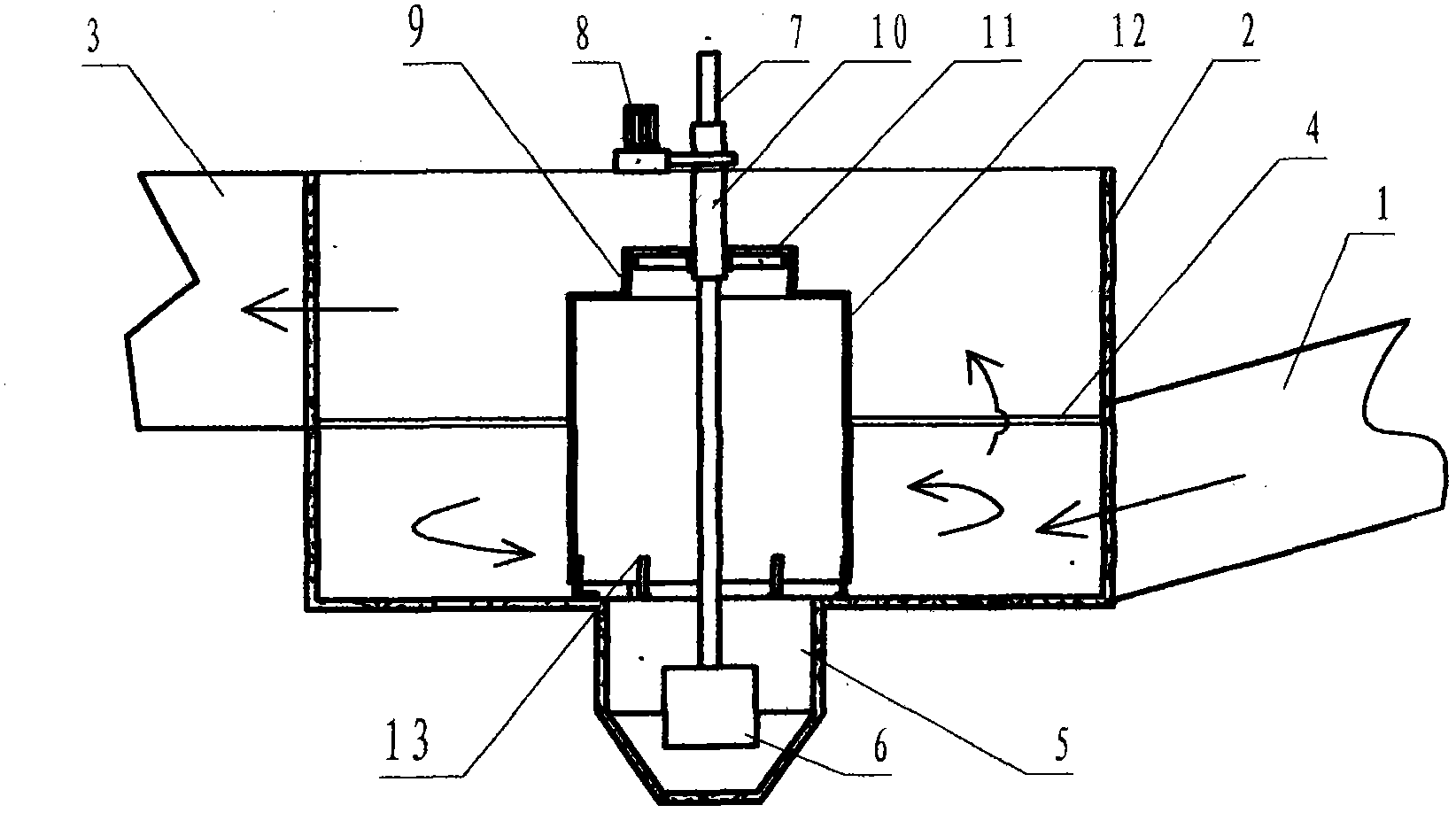

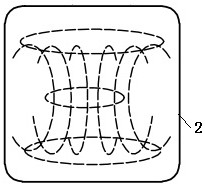

Rotational flow grit chamber with guide cylinder

ActiveCN102961903BEasy to collectSpeed up the flowCentrifugal force sediment separationImpellerEngineering

Owner:BEIJING DRAINAGE GRP CO LTD +1

Geological logging sand-washing device

InactiveCN109490052ARotation effectNormal rotationPreparing sample for investigationWell loggingRock cutting

The invention discloses a geological logging sand-washing device, and relates to the technical field of oil field well logging devices. The geological logging sand-washing device comprises an installing base, a sand-washing pool installed on the installing base and a sand-washing box positioned in the sand-washing pool. The sand-washing pool is fixedly provided with a cover plate. The cover plateis detachably connected with a fixing base. The fixing base is provided with a driving component. The driving component is connected with a transmission rod. One end of the transmission rod is fixedlyconnected with the output end of the driving component, and the other end passes through the fixing base and the cover plate and is rotatably connected with the bottom of the sand-washing pool. The transmission rod passes through the sand-washing box and is fixedly connected with the top and the bottom of the sand-washing box. The transmission rod is fixedly provided with a bearing plate. The bottom of the sand-washing box is fixedly connected with the bearing plate. The tail end of the transmission rod is fixedly connected with a reinforcement connecting plate which is used for reinforcing and supporting the bearing plate. The geological logging sand-washing device is capable of, through the driving component, driving the sand-washing box to be rotated in the sand-washing pool loaded with clear water, and enabling rock cuttings in the sand-washing box to be separated from a mud-slurry mixture, thereby achieving a purpose of sand-washing, and perfect in sand-washing effect.

Owner:刘永华

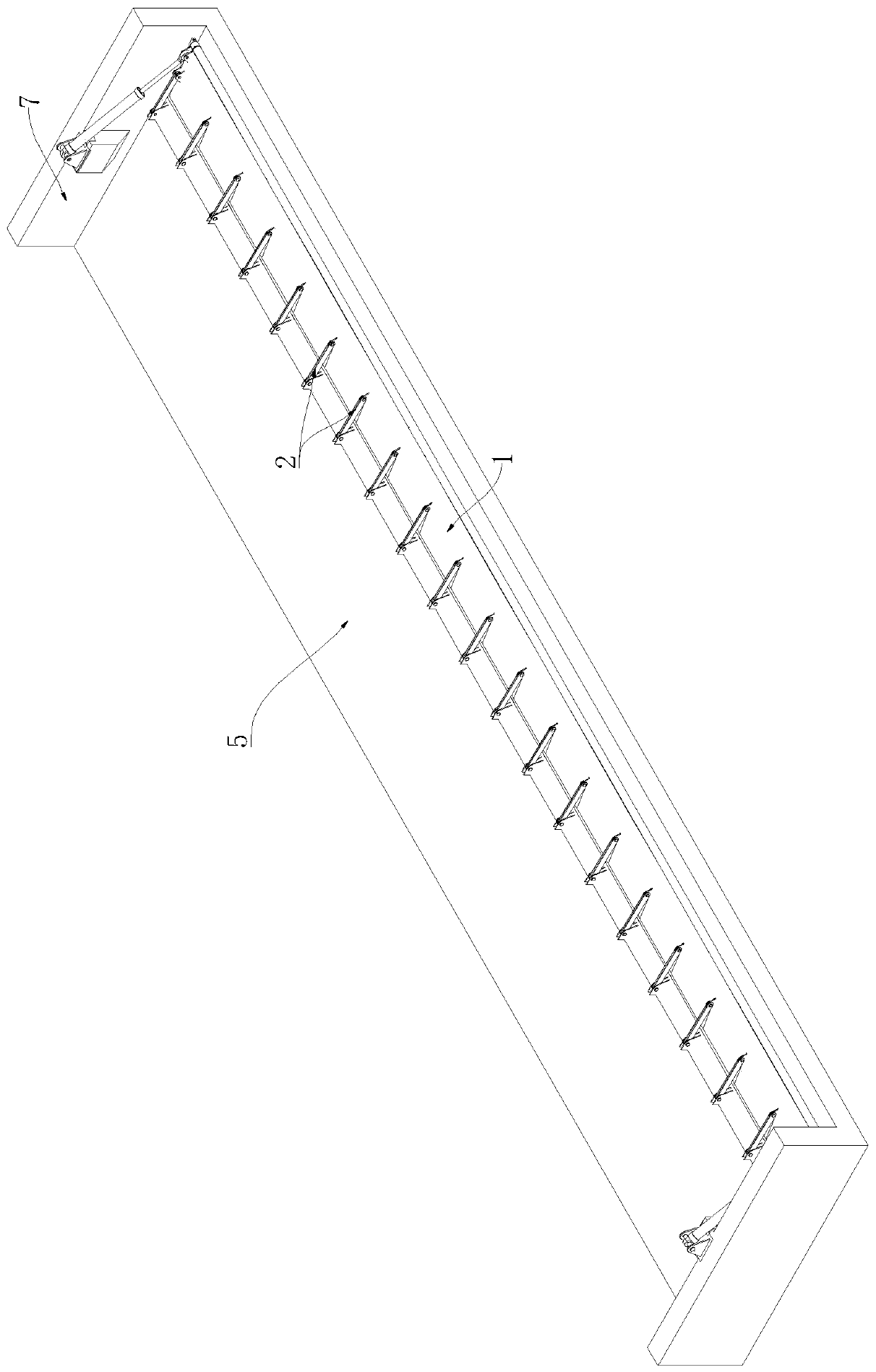

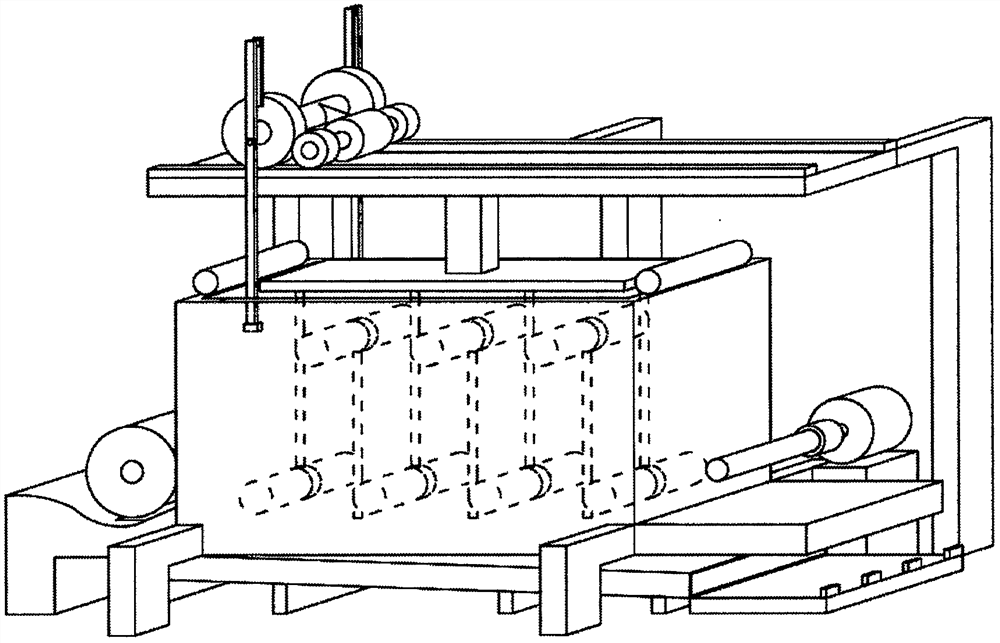

A kind of open-width sand washing machine

ActiveCN109594253BIncrease contact areaFast heatingTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentFiberMechanical engineering

The invention relates to an open-width sand washing machine, which includes an input end and an output end of a fabric fabric conveying path, and a high-pressure spray box for dry and wet spraying of fabric fabric samples on the fabric fabric conveying path. The microwave high-frequency electromagnetic box before the high-pressure spray box; the microwave high-frequency electromagnetic box uses the friction of the air medium in the microwave box to further rub the fabric fabric, so that the fabric fabric is opened and the fibers are fluffy; the microwave high-frequency electromagnetic box includes microwave The cavity and the array of multiple unit microwave generator components arranged on each surface of the microwave cavity emit microwaves to the fabric in the microwave cavity to cause friction on the fabric. The invention utilizes microwaves to open fibers of fabrics, has high production efficiency, good product quality and saves energy.

Owner:王佳茹

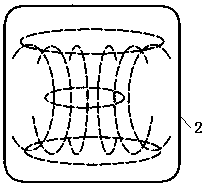

Open-width sand washing machine

ActiveCN109594253AIncrease contact areaStrong penetrating abilityTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentEngineeringHigh pressure

The invention relates to an open-width sand washing machine. The open-width sand washing machine comprises an input end and an output end of a fabric conveying path, the fabric conveying path furthercomprises a high-pressure spraying box for spraying a sample on a fabric in a dry or wet way and a microwave high-frequency electromagnetic box arranged in front of the high-pressure spraying box; themicrowave high-frequency electromagnetic box produces friction through an air medium in a microwave box so as to further rub the fabric, the fabric is opened and a fiber is fluffy; the microwave high-frequency electromagnetic box comprises a microwave cavity and a plurality of unit microwave generator component arrays distributed on various surfaces of the microwave cavity, and the unit microwavegenerator component arrays transmit microwaves to the fabric in the microwave cavity to produce friction. The fabric is opened through the microwave, the production efficiency is high, the product quality is good, and the energy is saved.

Owner:王佳茹

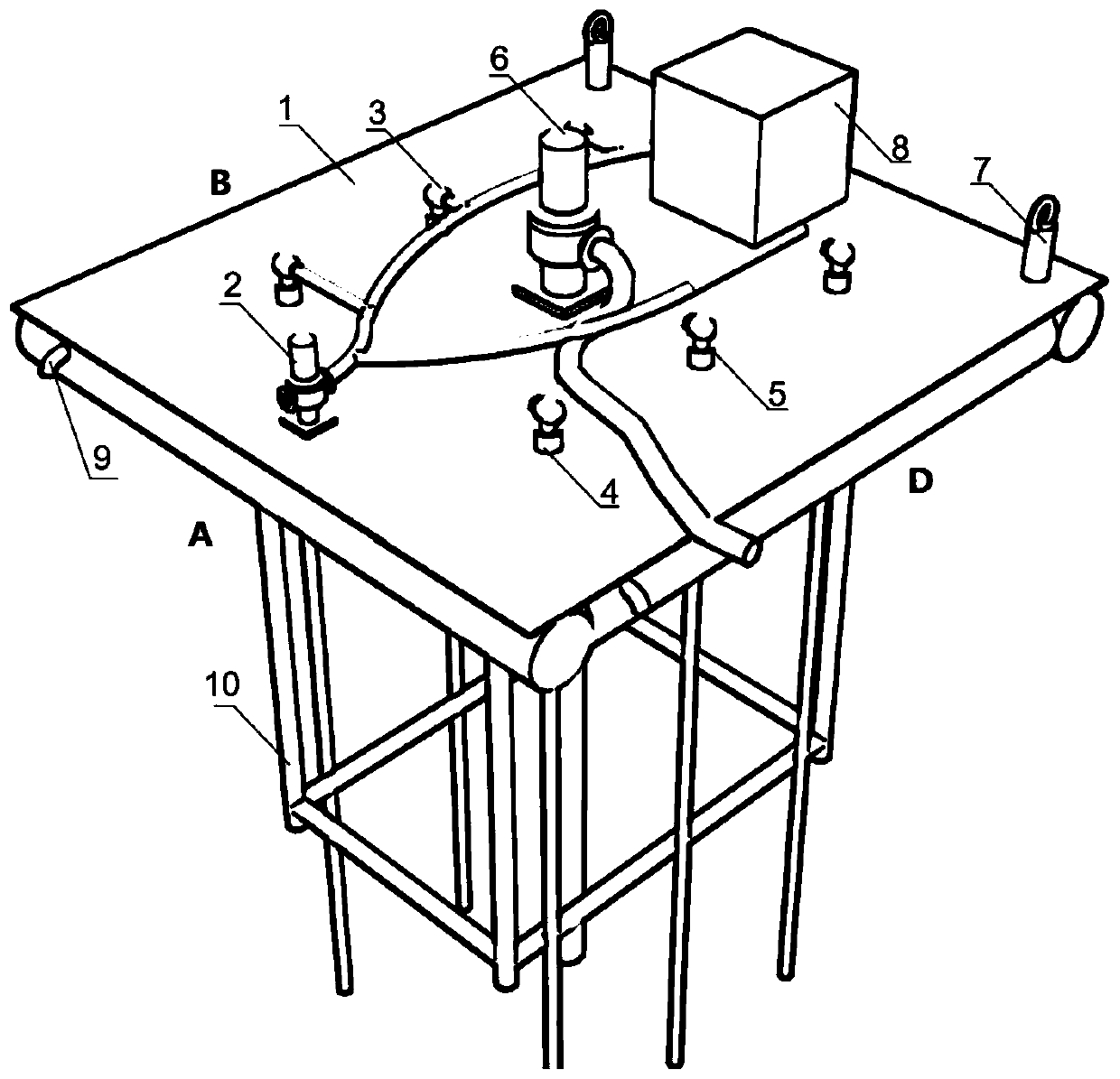

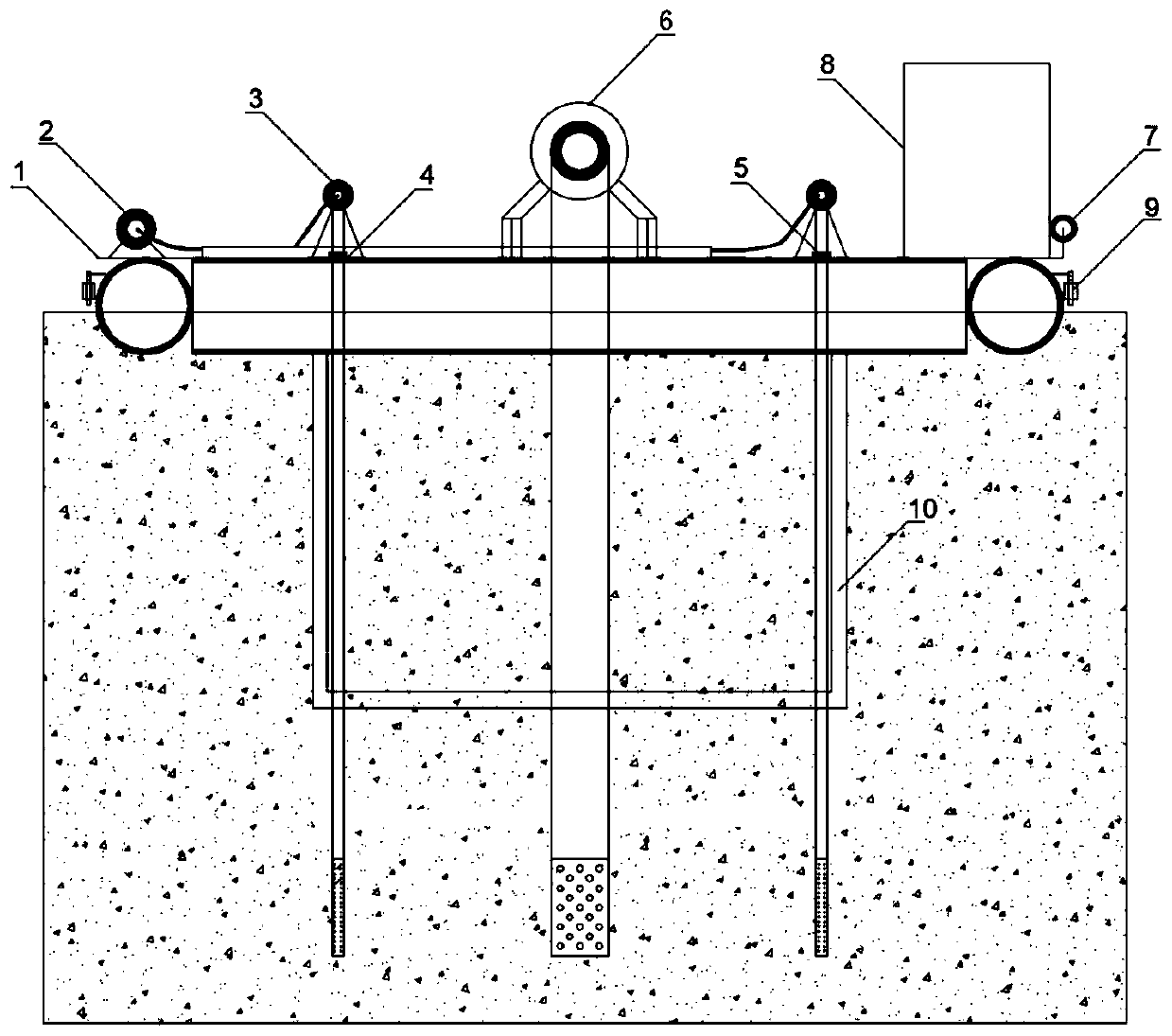

Hydraulic tailings taking platform for tailings reservoir of mine

ActiveCN109853652AImprove mining efficiencyIncrease production capacityMechanical machines/dredgersDrill holeRetaining ring

The invention discloses a hydraulic tailings taking platform for a tailings reservoir of a mine. The hydraulic tailings taking platform comprises a buoyant platform, a high-pressure pump, hydraulic giants, hydraulic giant fixing lantern rings, hydraulic giant fixing retaining rings, a tailings taking pump, a fixed guiding pile, an instrument operation table, a manual hoist crane, a fixed support,and the like. When tailings taking is carried out in the tailings reservoir, the high-pressure pump on the buoyant platform is started to form a high-pressure water jet; the high-pressure water jet issprayed from circular drilled holes arranged in the hydraulic giants to impact and loosen the tailings of a working surface in the tailings reservoir; the tailings are sucked in from a tailings suction opening of the tailings taking pump and flow out from a tailings outlet of the tailings taking pump to be conveyed to a predetermined position, and thus tailings can be taken from the tailings reservoir. The hydraulic tailings taking platform has the characteristics of being easy to manufacture, high in production efficiency, high in tailings taking capacity and low in cost, and is suitable forresource reuse of most wet tailings reservoirs (ponds) of mines and hydraulic tailings taking of other sites.

Owner:NANHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com