Movable well logging sand washing device

A technology of moving base and sand bucket, which is applied to cleaning hollow objects, wet separation, water/sludge/sewage treatment, etc. The cost of cleaning sand, the effect of sand washing is good, and the effect of improving sand washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

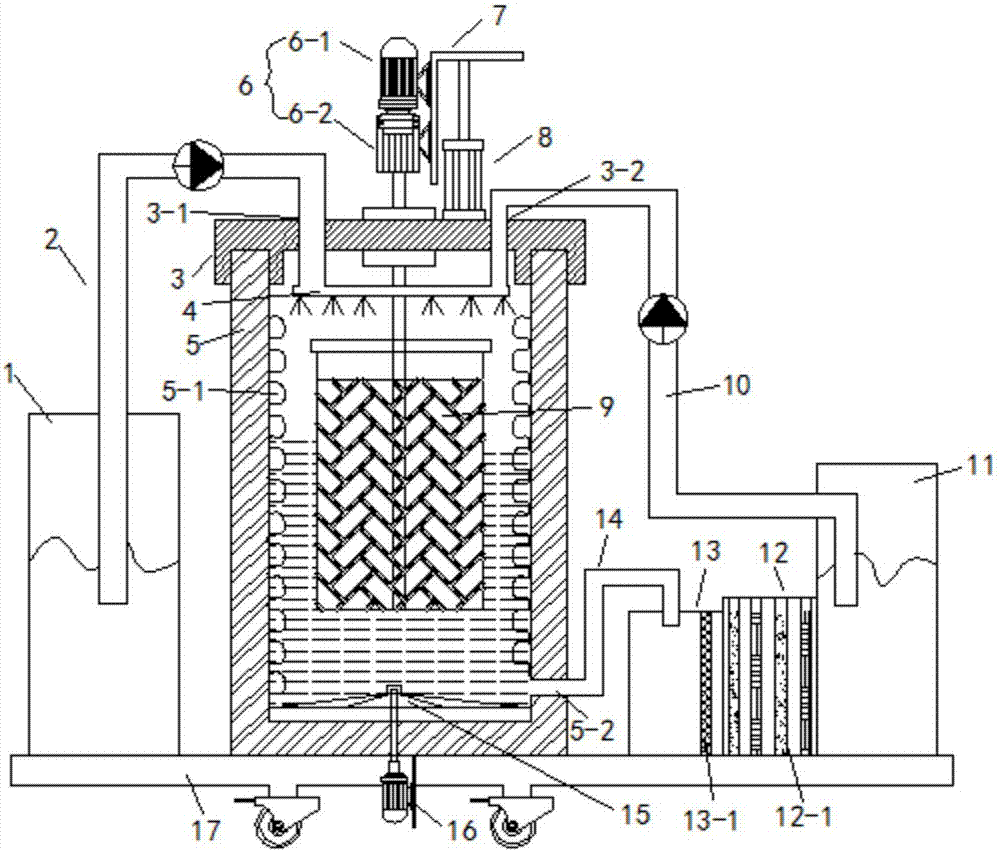

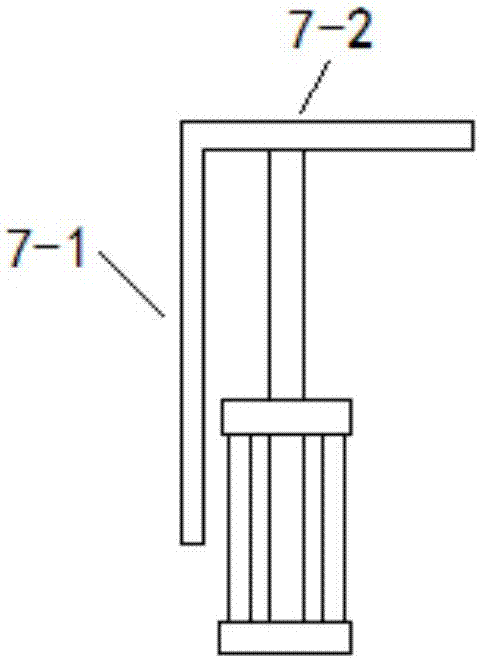

[0026] Such as Figure 1 to Figure 3 As shown, the present embodiment provides a movable mud logging sand washing device, comprising a mobile base 17, a sand cleaning tank 5 positioned on the mobile base 17 and a sand holding bucket 9 positioned in the sand cleaning tank 5, the sand cleaning The pool 5 is provided with a cover plate 3, and the cover plate 3 is dug with a water inlet, and the water inlet is connected with an annular water spray pipe 4 whose inner diameter is greater than the outer diameter of the sand holding bucket 9 in the sand cleaning tank 5. There is a water outlet 5-2 at the lower end of the pool wall, and the cover plate 3 is provided with a rotary drive assembly 6 and a lifting drive assembly 8 that drives the rotary drive assembly 6 to move up and down. The output end of the rotary drive assembly 6 extends through the cover plate 3 into the sand cleaning tank 5, and pass through the top of the sand tank 9 to be fixedly connected to the top and the bott...

Embodiment 2

[0029] This embodiment is further optimized on the basis of Embodiment 1, specifically:

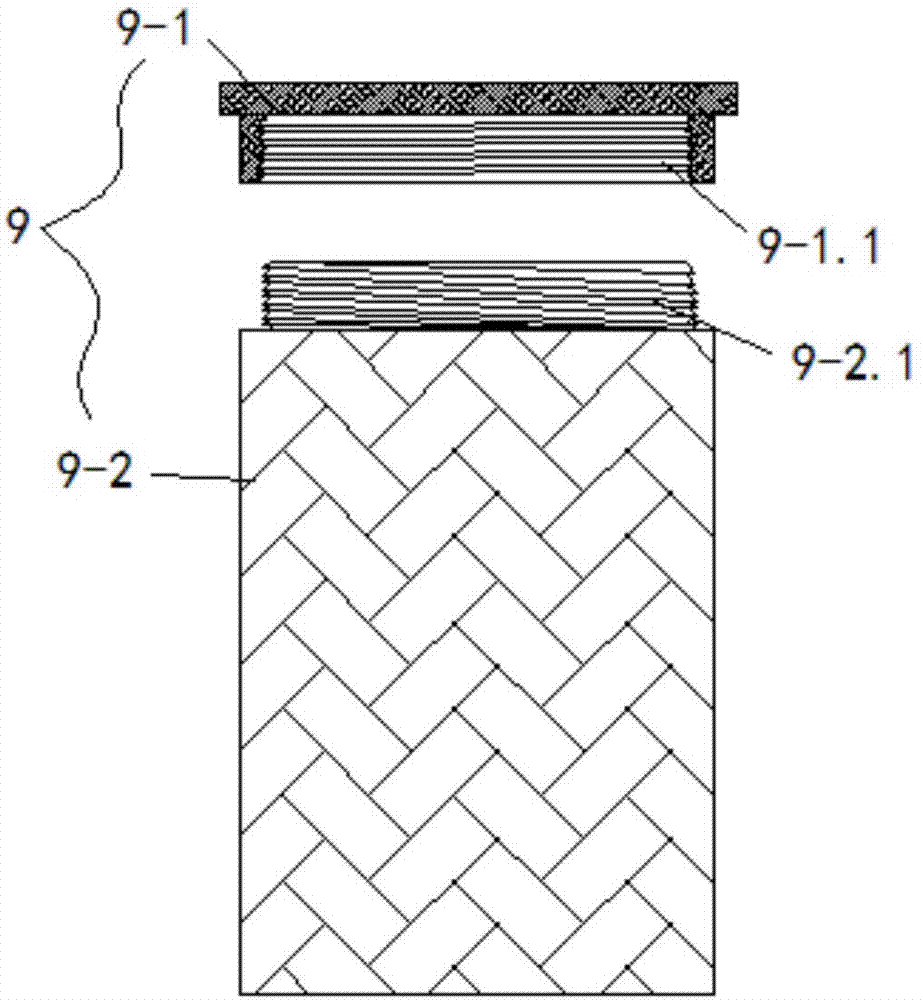

[0030]The sand holding bucket 9 includes a bucket cover 9-1 and a bucket body 9-2. The upper end of the bucket body 9-2 is open, and the opening is provided with an internal thread 9-2.1, and the inner wall of the bucket cover 9-1 is provided with a The external thread 9-1.1 matched with thread 9-2.1 is convenient to disassemble and open the sand bucket. The mobile base 17 is provided with a clean water tank 1 and a return water tank 11. The water inlet includes a clean water port 3-1 and a return water port 3- 2. The clean water tank 1 is connected with the clean water port 3-1 through the clean water pipe 2, the return water tank 11 is connected with the return water port 3-2 through the return water pipe 10, the return water tank 11 is connected with a secondary filter pool, and the water outlet 5-1 Communicate with the secondary filter tank through the water outlet pipe 14, the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com