Hydraulic tailings taking platform for tailings reservoir of mine

A technology of tailings pond and buoyancy platform, which is applied to mechanically driven excavators/dredgers, etc., can solve the problems of difficulty in meeting the requirements of mining enterprises for sand mining or temporary sand mining, low recovery efficiency and poor applicability, etc. Achieve the effect of low cost, high mining efficiency and large production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

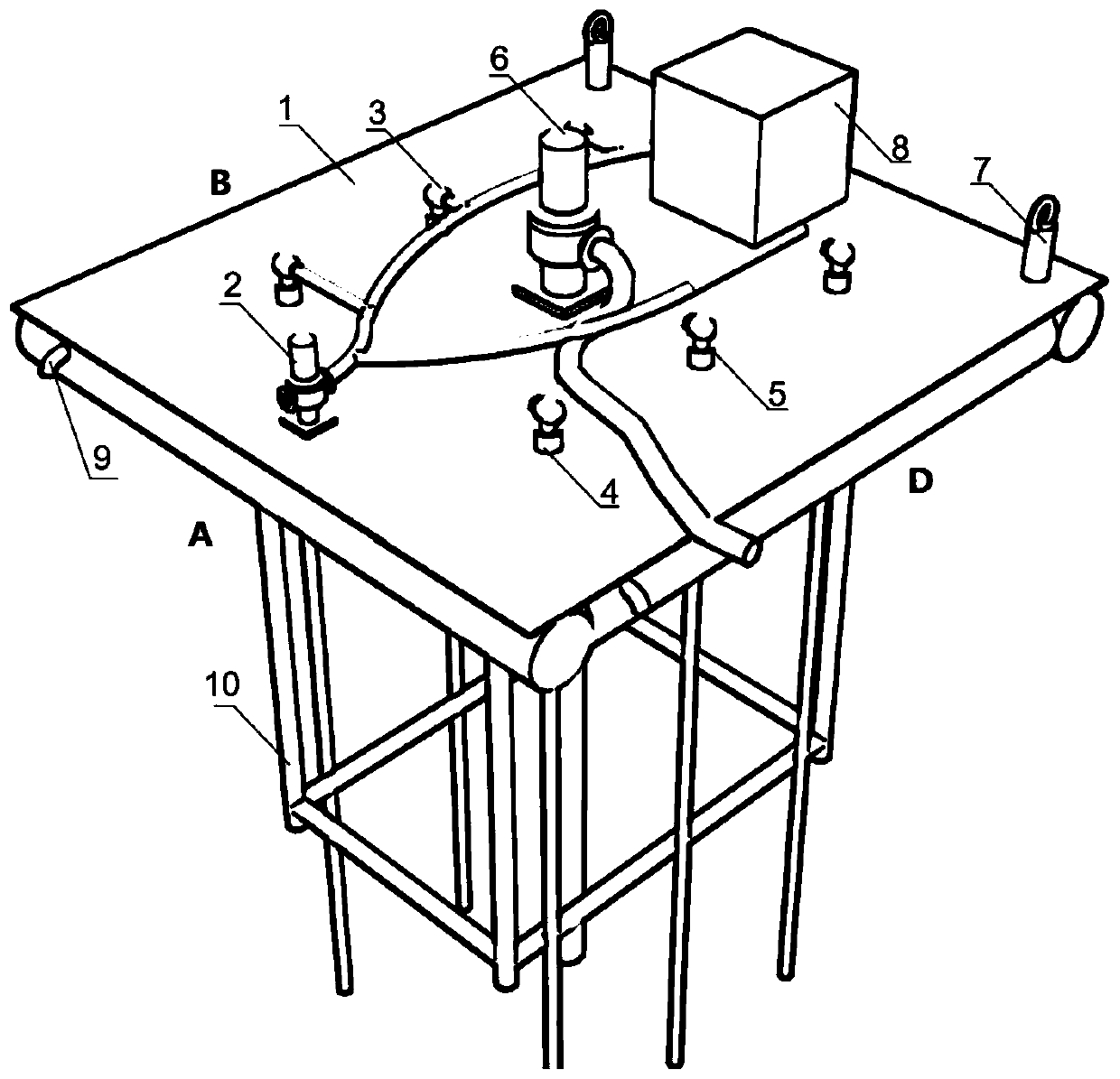

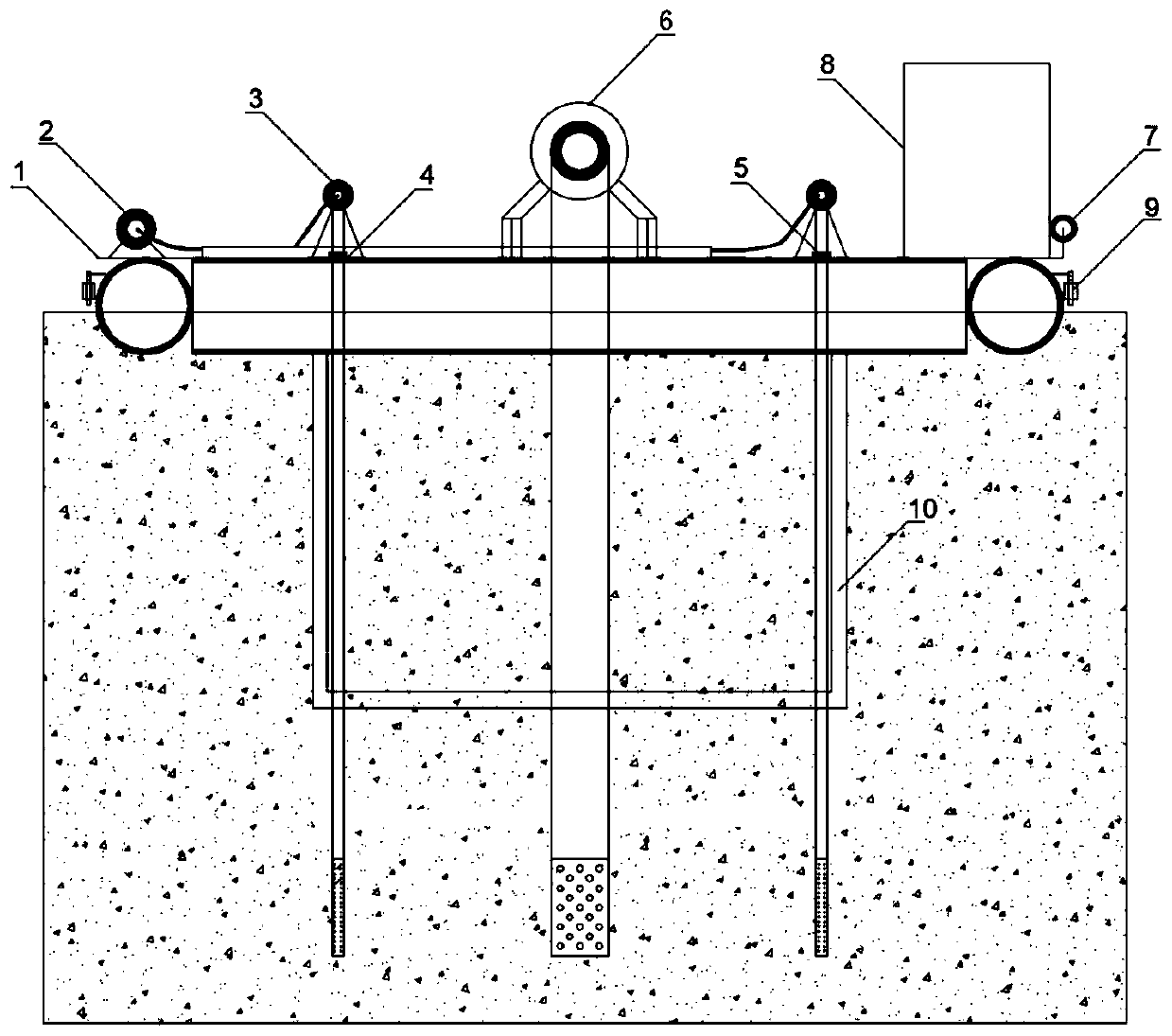

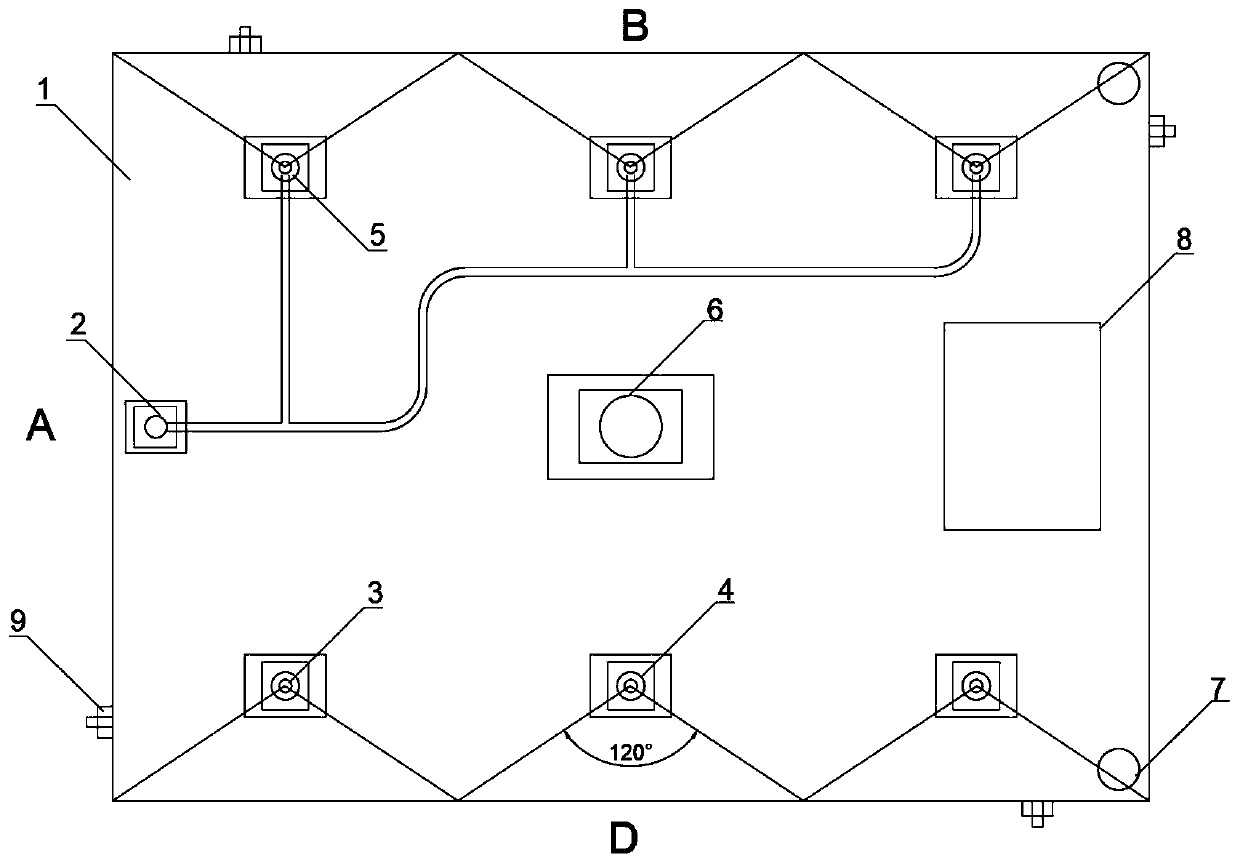

[0032] Such as Figure 1-Figure 6 As shown, the hydraulic sand extraction platform consists of a buoyancy platform 1, a high-pressure pump 2, a water gun 3, a water gun fixing collar 4, a water gun fixing buckle 5, a sand extraction pump 6, a fixed guide pile 7, an instrument console 8, and a manual hoist And fixed support 10 etc. are formed.

[0033] Among them, the buoyancy platform 1 is composed of four sealed large-diameter steel pipes with a diameter of Φ0.5-2.0m and with injection and drainage valves 9 at the ends. An annular hole for installing the water gun fixing collar 4 and the manual lifting hoist is reserved. The size of the buoyancy platform 1 is determined by the diameter of the steel pipe and the number of steel pipes. The number of steel pipes and the number of annular holes can be increased or decreased as required. The heig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com