Continuous positive and negative integrated sand washing device for oil well

A technology for sand flushing and oil wells, which is applied to the device for positive and negative sand flushing, and the continuous field of oil and water wells, can solve the problems of sand subsidence, affecting sand flushing efficiency, and weak sand flushing ability, and achieves good sand flushing effect and operation strength. The effect of low and high sand washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

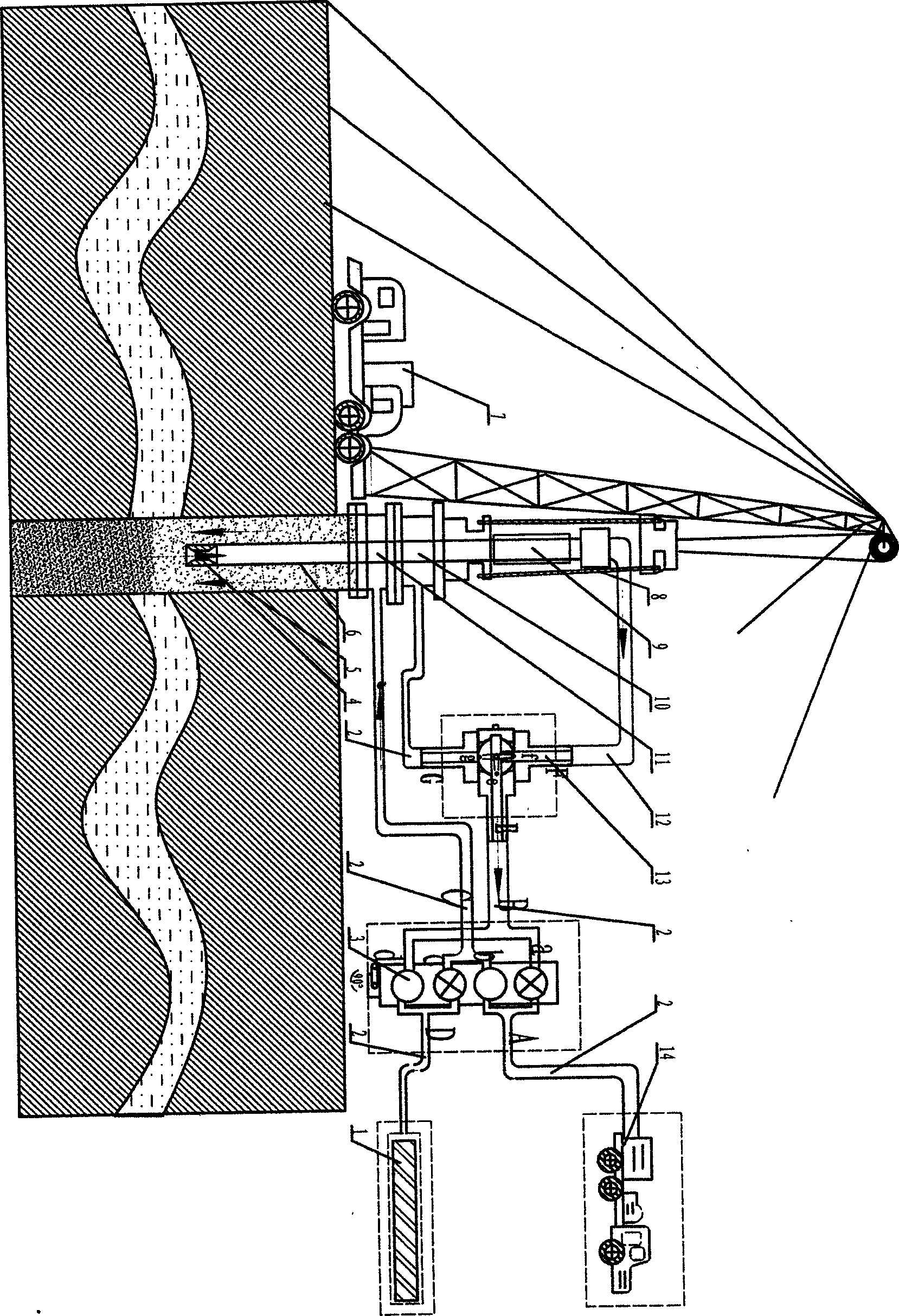

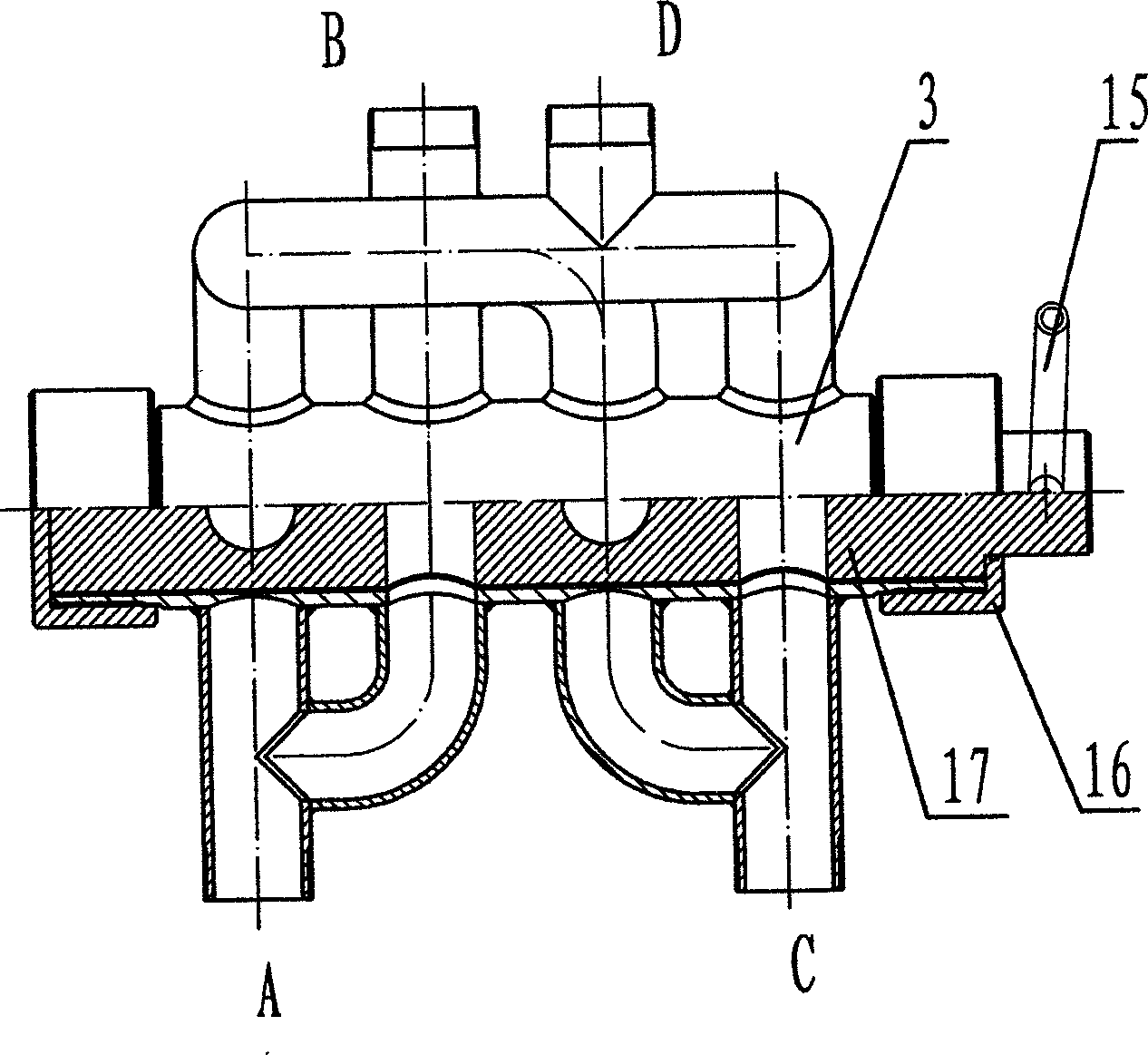

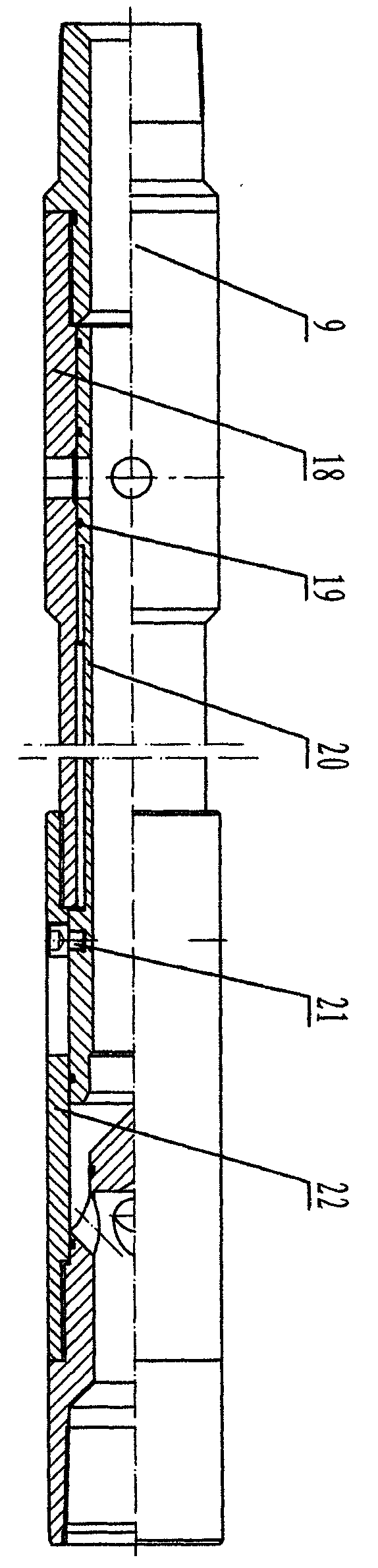

[0015] According to the accompanying drawings (such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Shown) do further explanation to the present invention: a kind of oil well continuous, positive and negative sand flushing device is made of: sewage tank 1, pipeline 2, positive and negative sand flushing regulating valve group 3, sand washing device 4, well casing 5 , sand washing pipe 6, operating machine 7, elevator 8, reversing valve 9, self-sealing wellhead 10, large four-way 11, hose 12, three-way valve 13 and pump truck 14; it is characterized in that: operating machine 7 passes through The elevator 8 is connected to the sand washing pipe 6 to control the lifting of the sand washing pipe 6; a self-sealing wellhead 10 is installed at the upper end of the large four-way 11, a sand washing device 4 is installed at the lower end of the sand washing pipe 6, and a reversing valve 9 is installed at the upper end , the sand washing pipe 6 is lowered into the downh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com