A cloth sand washing device

A technology of sand washing and cloth, which is applied in the direction of processing textile material carriers, textile material containers, textiles and papermaking, etc., can solve problems such as uneven sand washing, cloth transmission wrinkles, and cloth damage, so as to promote uniform sand washing and save Removing manual operation and avoiding the effect of abrasive damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

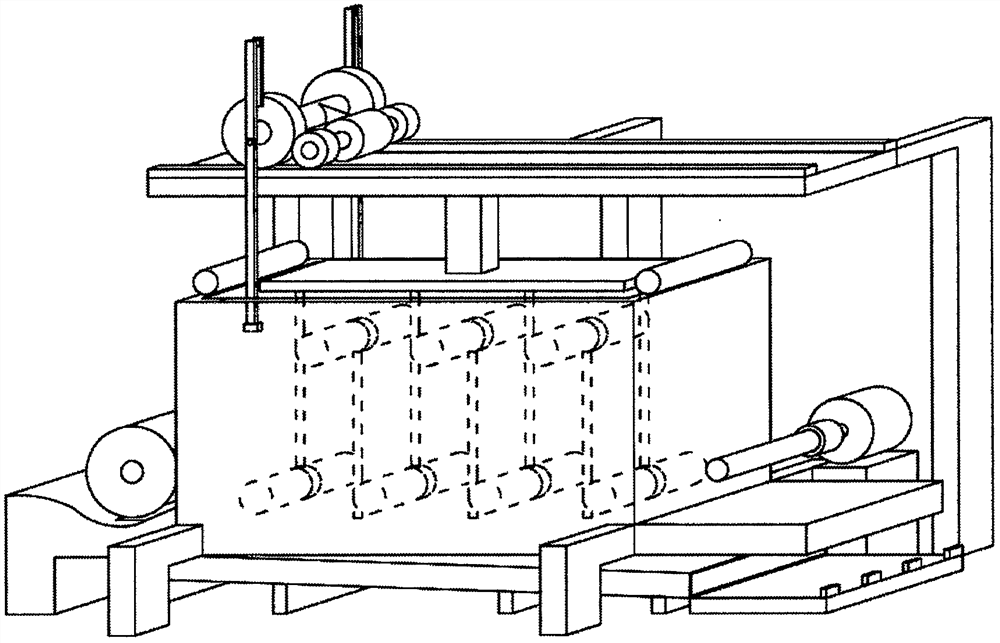

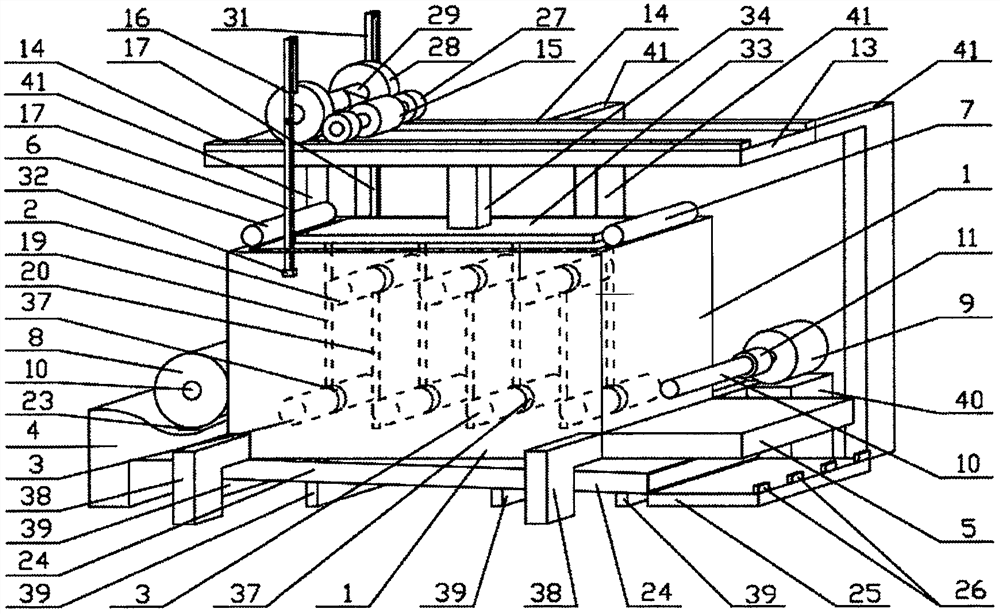

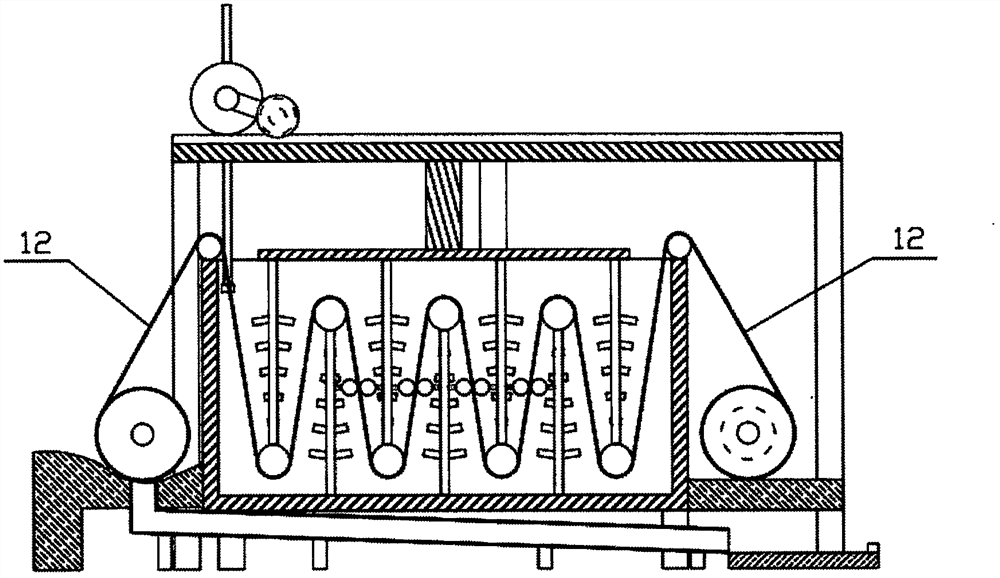

[0036] like Figure 1 to Figure 4 The shown cloth sand washing device includes a sand washing box 1, and the sand washing box 1 is provided with an upper row of rollers 2 and a lower row of rollers 3 arranged equidistantly from the upper row of rollers 2. 1 is filled with sand washing liquid whose liquid level is higher than that of the upper row of rollers 2. The outside of the two ends of the sand washing box 1 is provided with a cloth feeding support table 4 and a cloth rolling support table 5. The top of the sand washing box 1 is two The end sides are respectively provided with a cloth feeding roller 6 and a cloth discharging roller 7. The cloth roll 8 to be sand washed is placed on the cloth feeding support table 4. Rotating motor 9, the output shaft of said rotating motor 9 is provided with a mounting sleeve 11 for installing the winding shaft 10 of the cloth roll 8. During the sand washing process, the cloth 12 shuttles in an "S" shape between the upper rollers 2 and 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com