Two-way passageway check valve and method for conducting sand-flushing through the same

A two-way channel and one-way valve technology, which is applied in the direction of flushing wellbore, earthwork drilling, wellbore/well components, etc., can solve the problems of large flowback channel cross-section, low flowback flow rate, and inability to carry out reverse circulation flushing, etc. , to achieve the effect of smaller channel cross-section, increased flowback flow rate, and improved sand washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

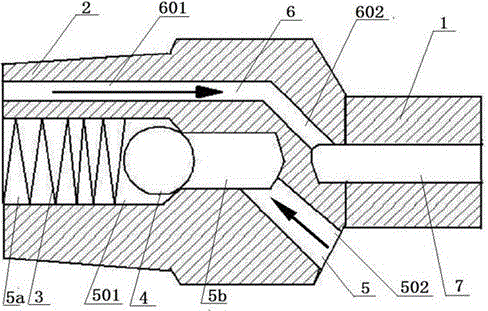

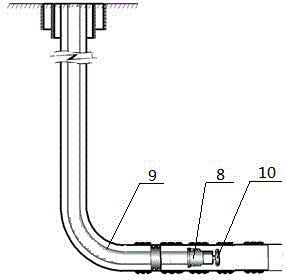

[0037] like figure 1 and figure 2 As shown, the upper end of the two-way channel check valve 8 is provided with an upper joint 1 for connecting with the rotary jet sand washing device 10, and the lower end is provided with a lower joint 2 for connecting with the oil pipe 9, and the upper joint 1 is provided with a diversion channel. 7. The lower joint 2 is provided with a forward channel 6 and a reverse channel 5 parallel to the forward channel 6 , and the reverse channel 5 is provided with a valve ball 4 and a spring 3 .

[0038] During positive circulation flushing, the flushing fluid enters the forward channel 6 from the tubing 9, and the spring 3 is compressed due to the thrust of the flushing fluid, so that the spring 3 and the valve ball 4 are in closer contact, and the gap between the two is smaller , the valve ball 4 is closed, the well washing fluid flows into the diversion channel 7 through the forward channel 6, and then enters the rotary jet sand washing device 1...

Embodiment 2

[0041] On the basis of embodiment 1, further, such as figure 1 As shown, the forward channel 6 includes a horizontal forward channel 601 and an oblique forward channel 602, the horizontal forward channel 601 communicates with the oblique forward channel 602, and the oblique forward channel 602 communicates with the guide channel 7 .

[0042]During positive circulation flushing, the flushing fluid enters the forward channel 6 from the tubing 9, and the spring 3 is compressed due to the thrust of the flushing fluid, so that the spring 3 and the valve ball 4 are in closer contact, and the gap between the two is smaller , the valve ball 4 is closed, the well flushing fluid first enters the horizontal forward passage 601 in the forward passage 6, and then enters the oblique forward passage 602. Due to the inclination of the oblique forward passage 602, under the action of gravity, the well flushing The liquid flows into the diversion channel 7 and enters the rotary jet sand washer...

Embodiment 3

[0045] On the basis of Embodiment 1, the reverse channel 5 includes a horizontal reverse channel 501 and an oblique reverse channel 502, the horizontal reverse channel 501 communicates with the oblique reverse channel 502, and the oblique reverse channel 502 is downward tilt.

[0046] During positive circulation flushing, the flushing fluid enters the forward channel 6 from the tubing 9, and the spring 3 is compressed due to the thrust of the flushing fluid, so that the spring 3 and the valve ball 4 are in closer contact, and the gap between the two is smaller , the valve ball 4 is closed, the flushing fluid enters the forward passage 6, then enters the diversion passage 7, and enters the rotary jet sand washer 10, and the well flushing fluid drives the rotary jet sand flusher 10 to form a rotary jet and pressure vibration in the horizontal well section , under the impact and agitation of the flushing fluid, the consolidated sand accumulation in the horizontal well section is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com