Rotational flow grit chamber with guide cylinder

The technology of a swirl grit chamber and a guide tube is applied in the field of water treatment, which can solve the problems of insufficient elution effect, scattered sand particles, and insufficient effect, so as to increase the effect of sand washing, simple production process and less consumption of materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

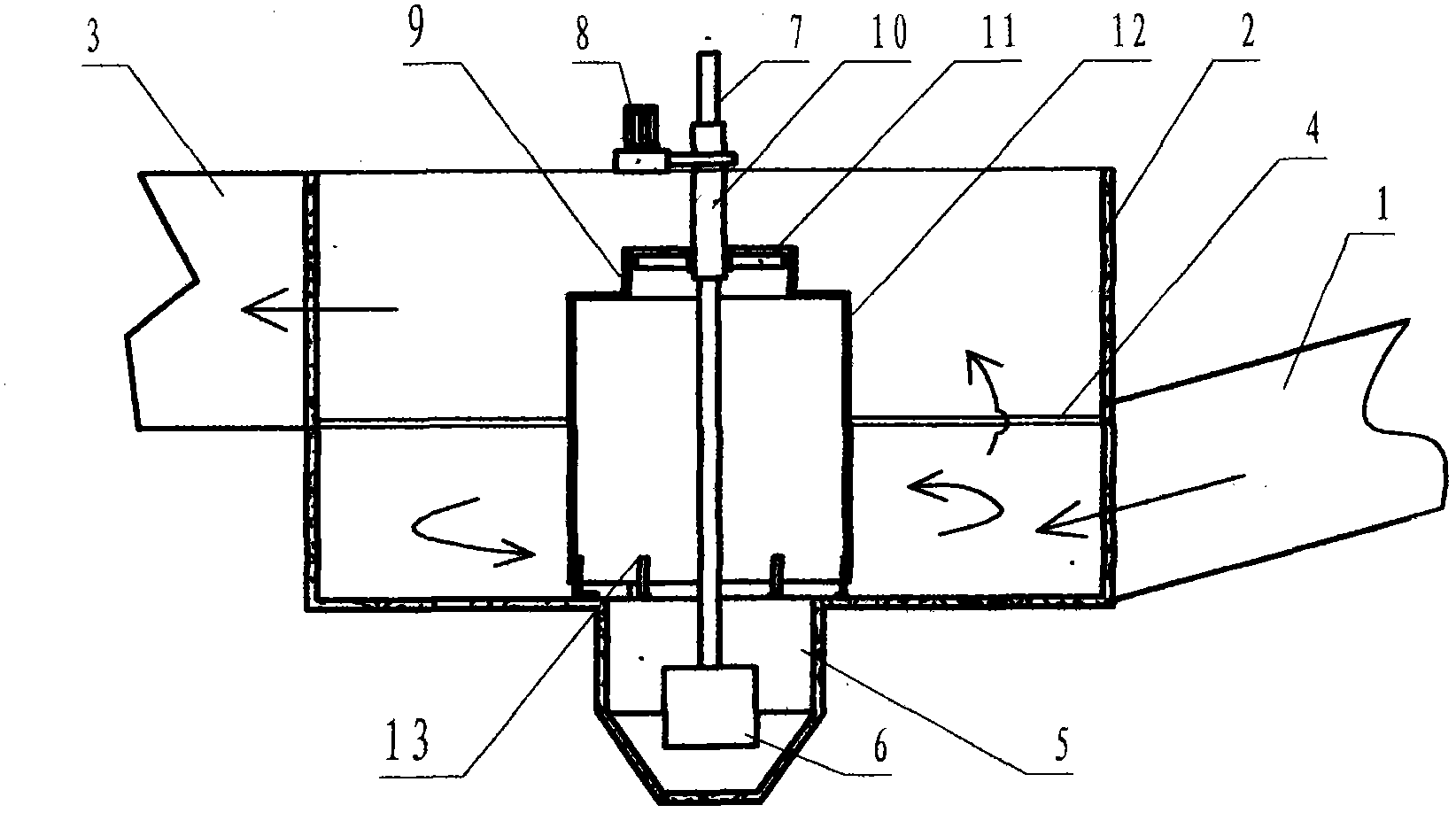

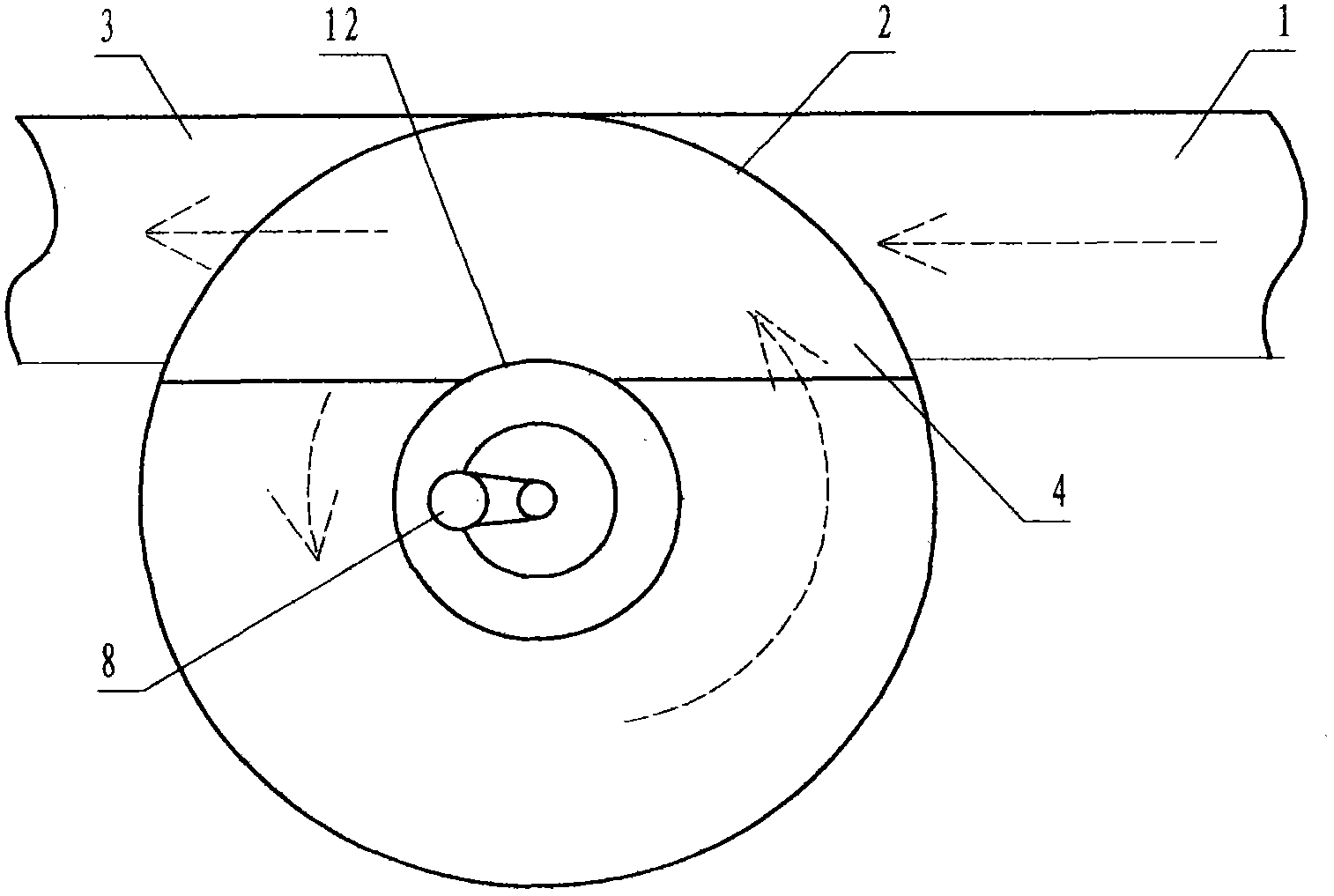

[0016] Below in conjunction with the accompanying drawings and Examples, the present invention will be further described, embodiment: with reference to the accompanying drawings, a kind of cyclone grit chamber with a guide tube is provided with a main tank body 2, and the pond wall of this main tank body is a cylinder A water inlet is provided on one side of the center of the bottom of the pool to communicate with the water inlet end 1 of the water delivery channel. It is communicated with the water outlet end 3 of the water delivery channel, and is characterized in that: a partition plate 4 is arranged on the side of the main tank body on the side of the water inlet and outlet, and the partition plate is arranged horizontally, and the water inlet is below the partition plate. The water outlet is above the clapboard, the clapboard is semi-circular, and its outer edge is closely connected with the pool wall; a sand collecting bucket 5 is arranged at the bottom center of the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com