Sand washing machine with automatic feeding function

An automatic feeding and sand washing machine technology, applied in the field of sand washing machines, can solve the problems of low feeding efficiency, short sand washing time, turbidity, etc., and achieve high feeding efficiency and good initial purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

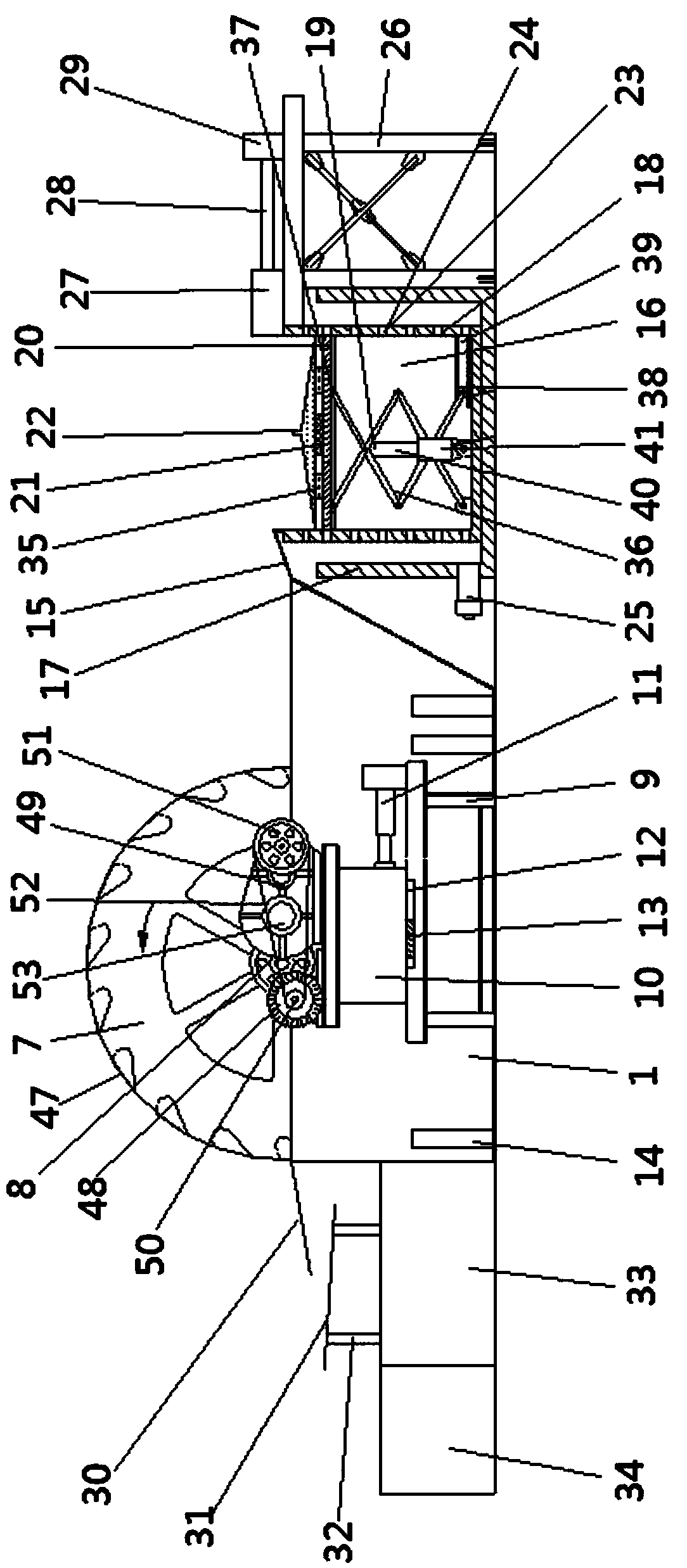

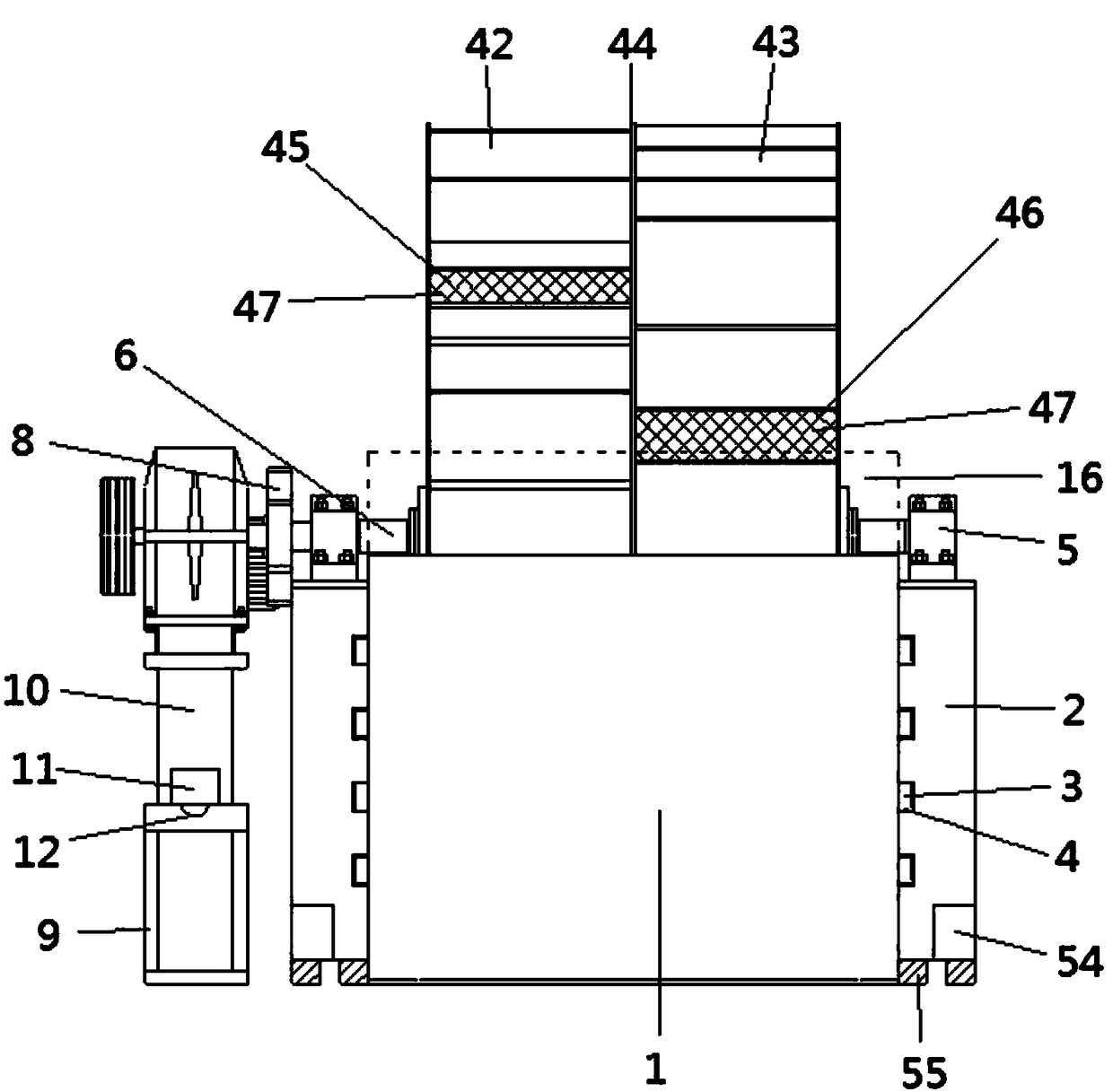

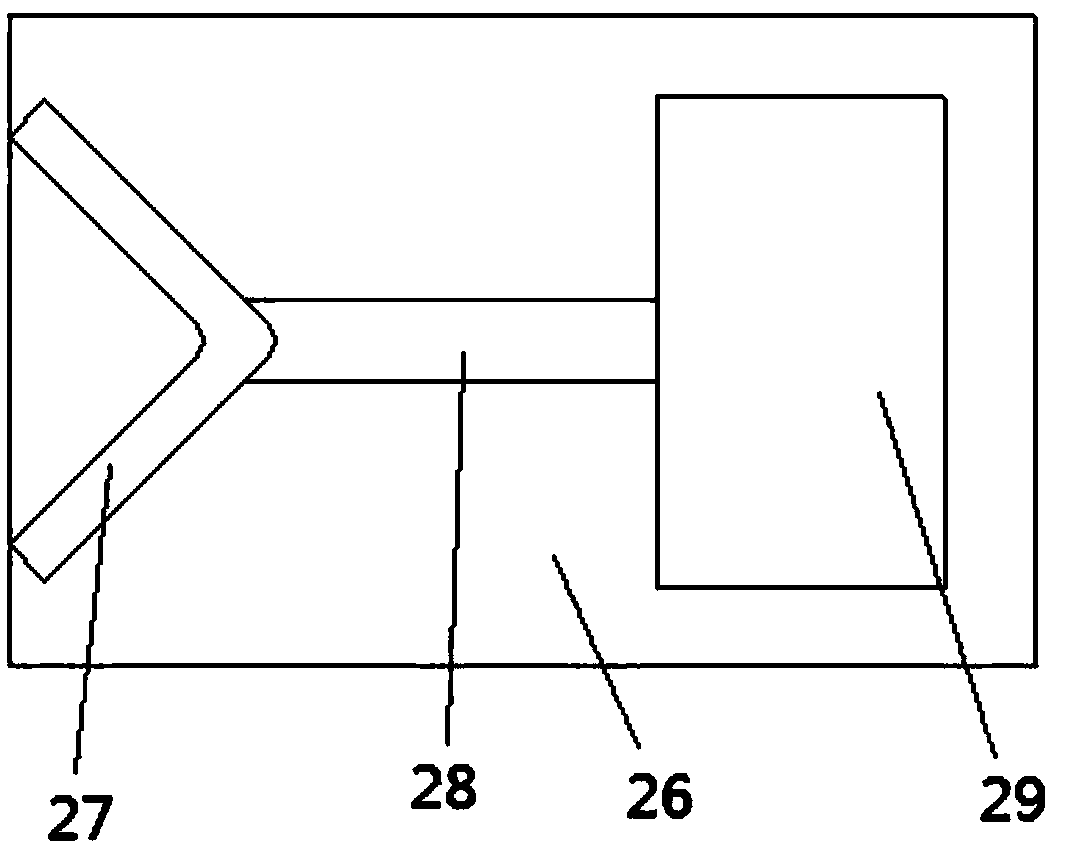

[0019] Example: a sand washing machine with automatic feeding function, the structure is as follows Figures 1 to 3 As shown, it includes a sand washing tank 1, and both sides of the sand washing tank 1 are connected with a mobile platform 2, and the side wall of the mobile platform 2 is provided with several parallel sliding guide rails 3, and the side wall of the sand washing tank 1 is provided with The guide rail slide bar 4 matched with the sliding guide rail 3, the wheel shaft mounting seat 5 is fixed on the mobile platform 2, the wheel shaft 6 is arranged between the two wheel shaft mounting seats 5, and the impeller group 7 is arranged on the wheel shaft 6 in the sand washing tank 1. Wheel shaft 6 is also provided with pinion 8; Sand washing tank 1 outside is provided with fixed support 9, and fixed support 9 is provided with mobile support 10, and fixed support 9 is provided with the electrical connection that is connected with mobile support 10. Liquid push rod 11; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com