Sand washing device for geological logging

A technology for geological logging and sand washing, applied in solid separation, wet separation, chemical instruments and methods, etc., can solve problems such as inability to accurately reflect the stratification of cuttings, unsatisfactory sand washing effect, etc., and achieve good sand washing effect. , Improve the efficiency of sand washing and reduce the effect of offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

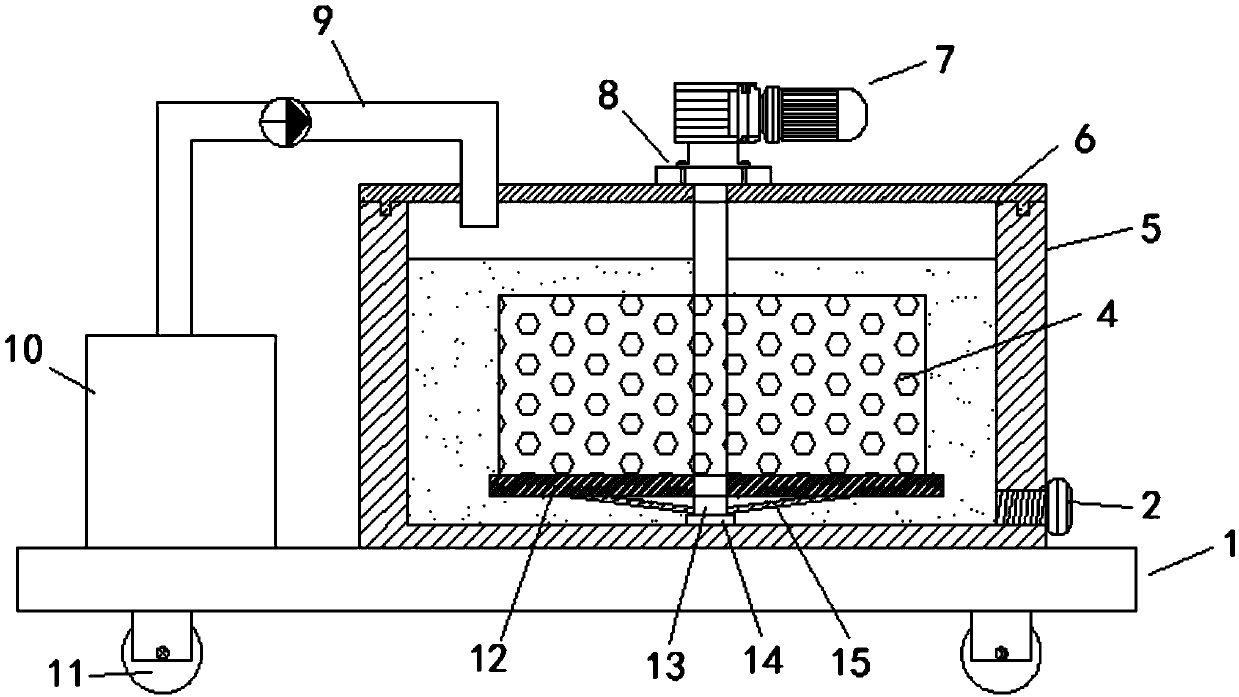

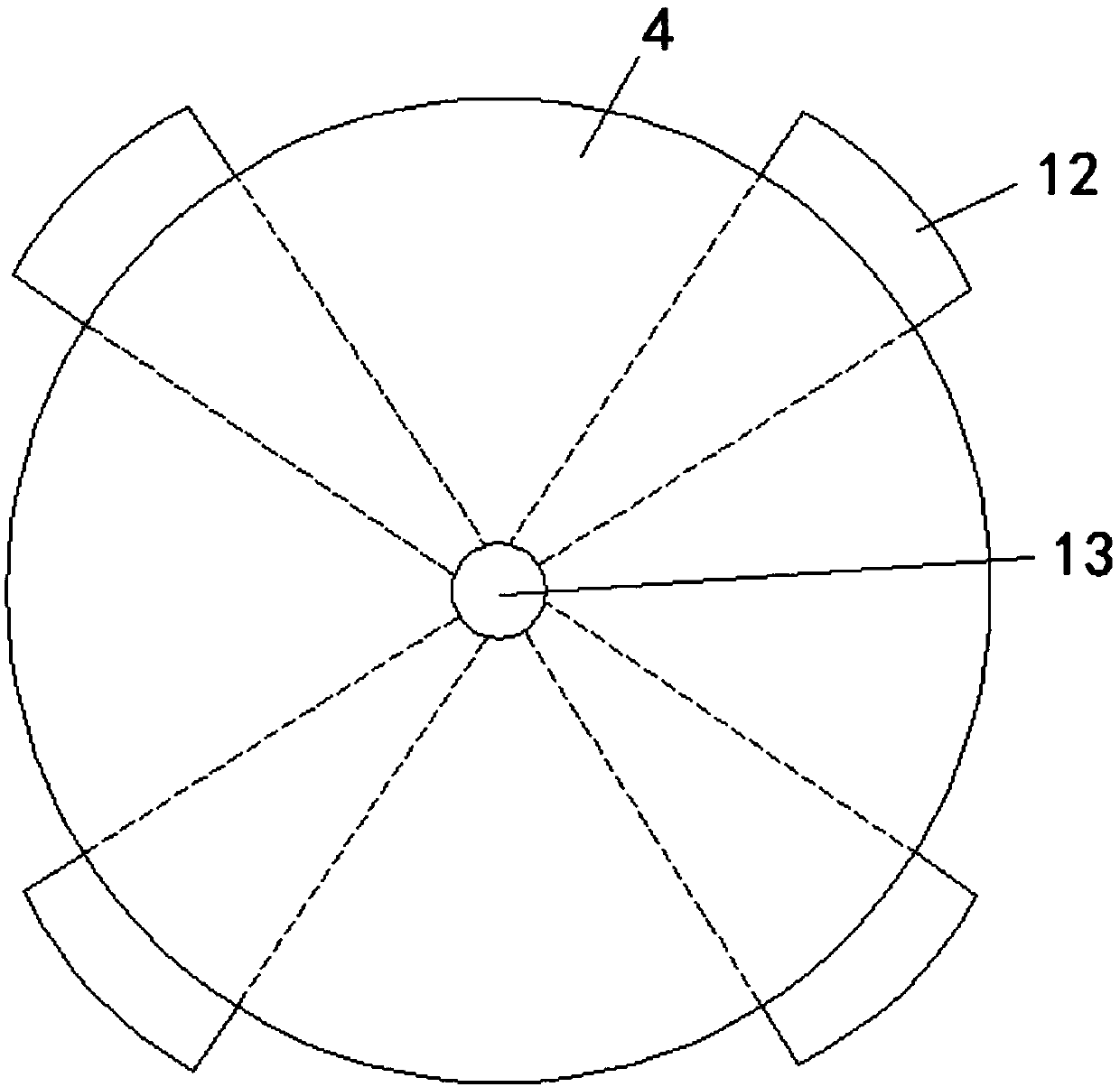

[0024] Such as figure 1 and figure 2 As shown, the present embodiment provides a sand washing device for geological mud logging, including a mounting base 1, a sand washing tank 5 arranged on the mounting base 1, and a sand washing box 4 located in the sand washing tank 5. The sand washing tank 5 is fixed with a cover plate 6, the upper opening of the sand washing tank 5 is provided with a groove, the cover plate 6 is provided with a protrusion matching the groove, and the cover plate 6 is detachably connected by bolts. There is a fixed seat 8, and the fixed seat 8 is provided with a drive assembly 7, and the drive assembly 7 includes a motor and a reducer connected to the output shaft of the motor, the output end of the reducer is fixedly connected to one end of the transmission rod 13, and the The other end passes through the fixed seat 8 and the cover plate 6 and is connected with the bearing seat 14 arranged at the bottom of the sand washing tank 5. The part of the trans...

Embodiment 2

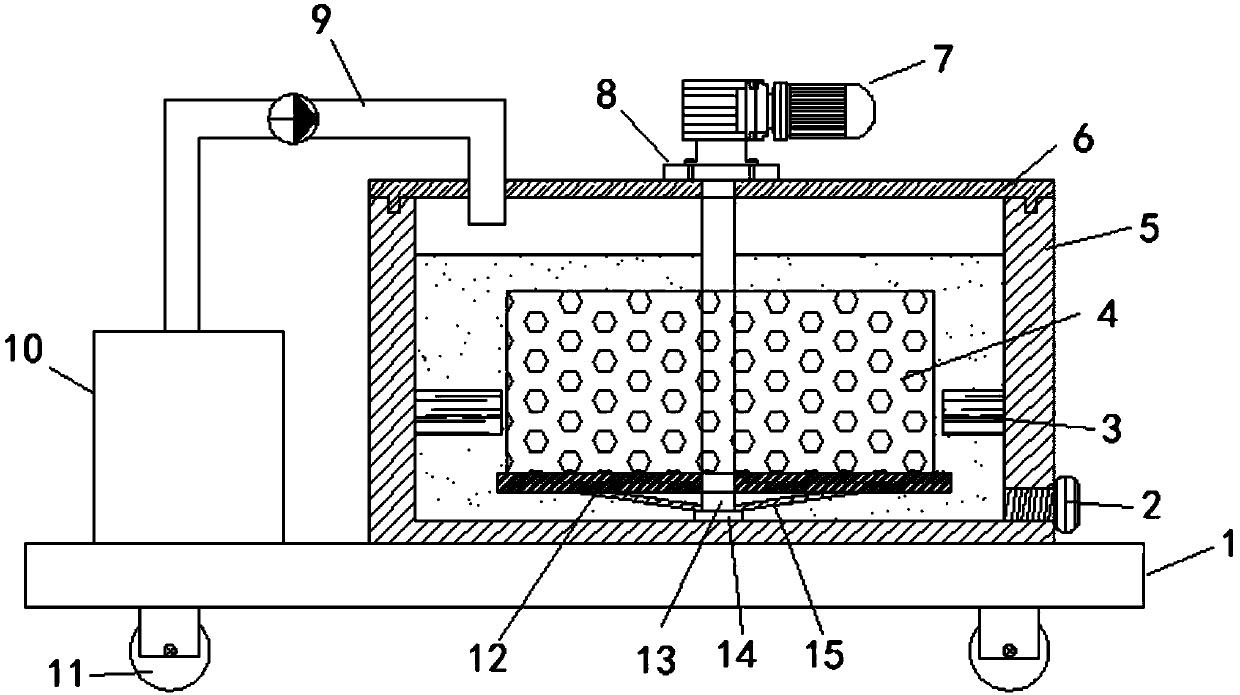

[0026] Such as image 3 As shown, this embodiment is further optimized on the basis of Embodiment 1, specifically: the inner walls of the opposite sides of the sand washing tank 5 are respectively fixed with elastic components 3, when the sand washing tank 4 is rotating due to When a large degree of horizontal deviation occurs due to uneven load bearing, the symmetrically arranged elastic components 3 can reduce the deviation and avoid the sand washing box 4 being rotated due to the uneven distribution of cuttings and mud mixture in the sand washing box 4. When the deviation is large, the connection between the transmission rod 13 and the output end of the reducer is caused to come off, causing sand washing to be interrupted, which affects the smooth development of the work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com