Three-phase motor rotor

A technology of three-phase motors and rotors, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of sparks and inability to use, and achieve the effect of preventing excessive temperature and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

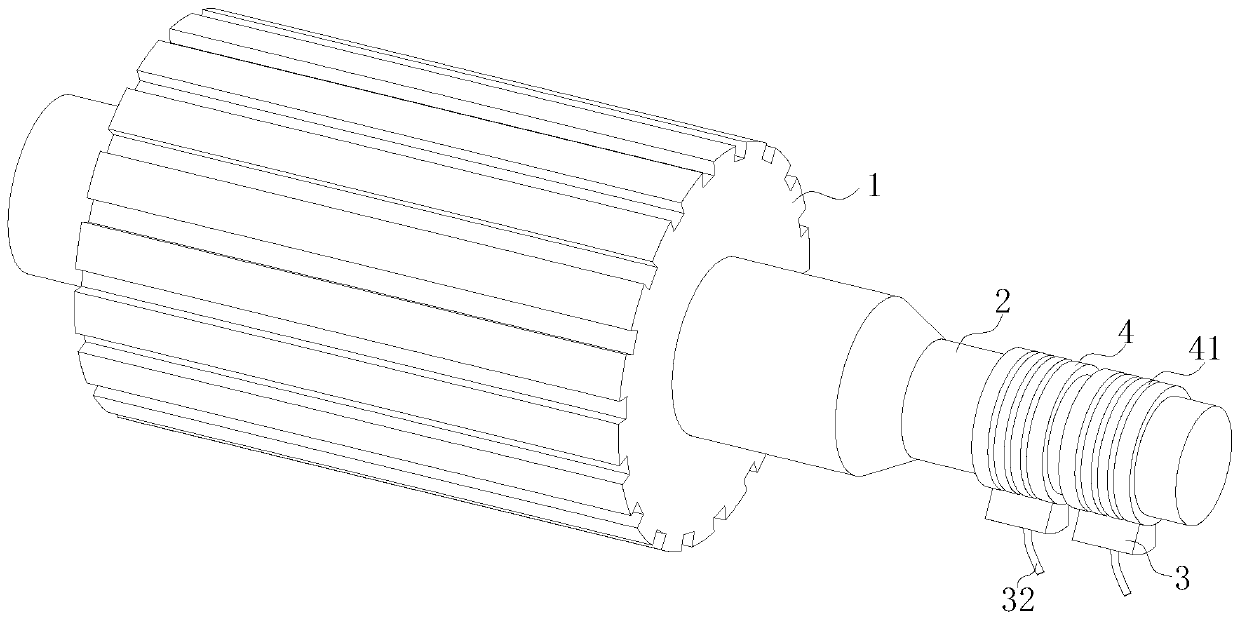

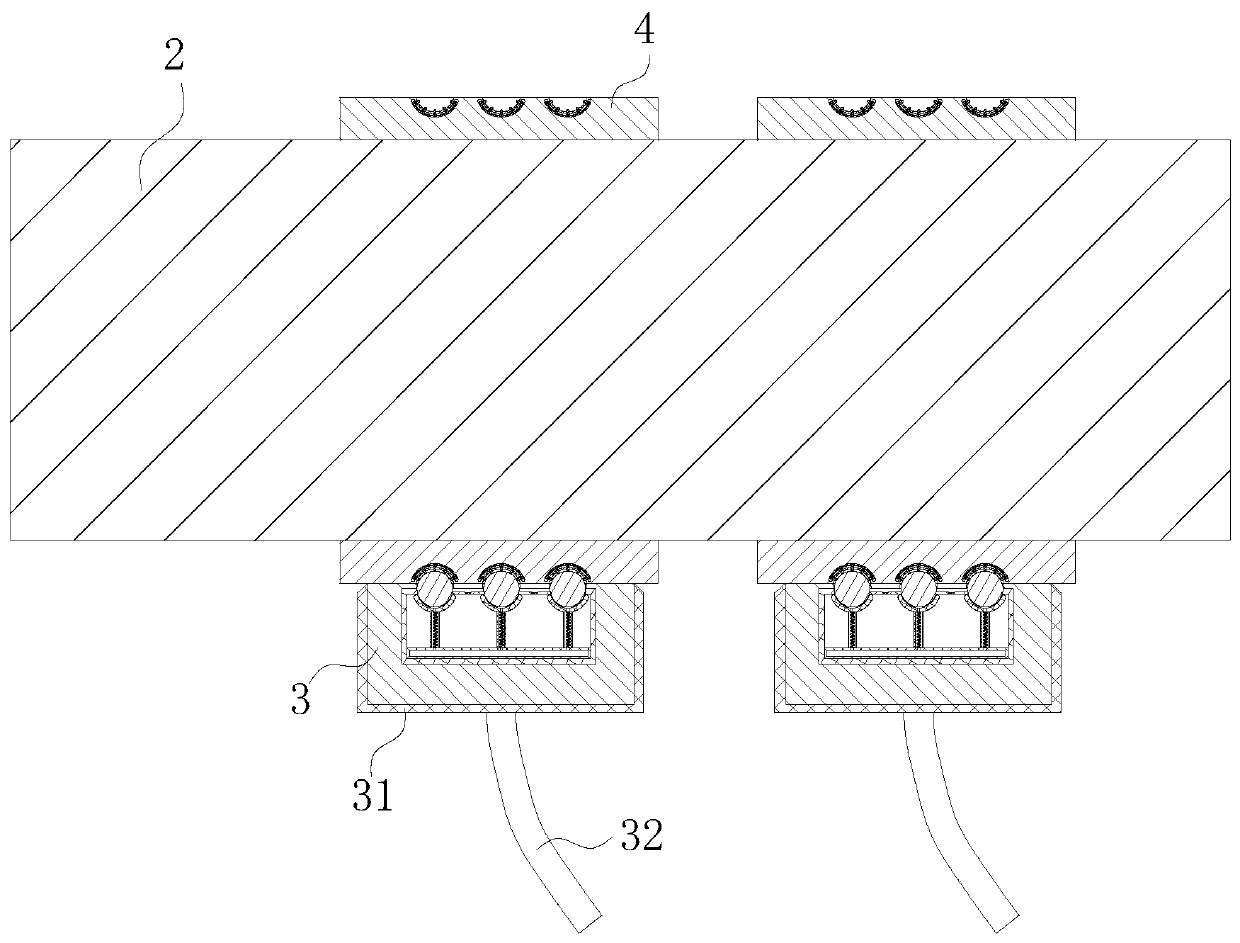

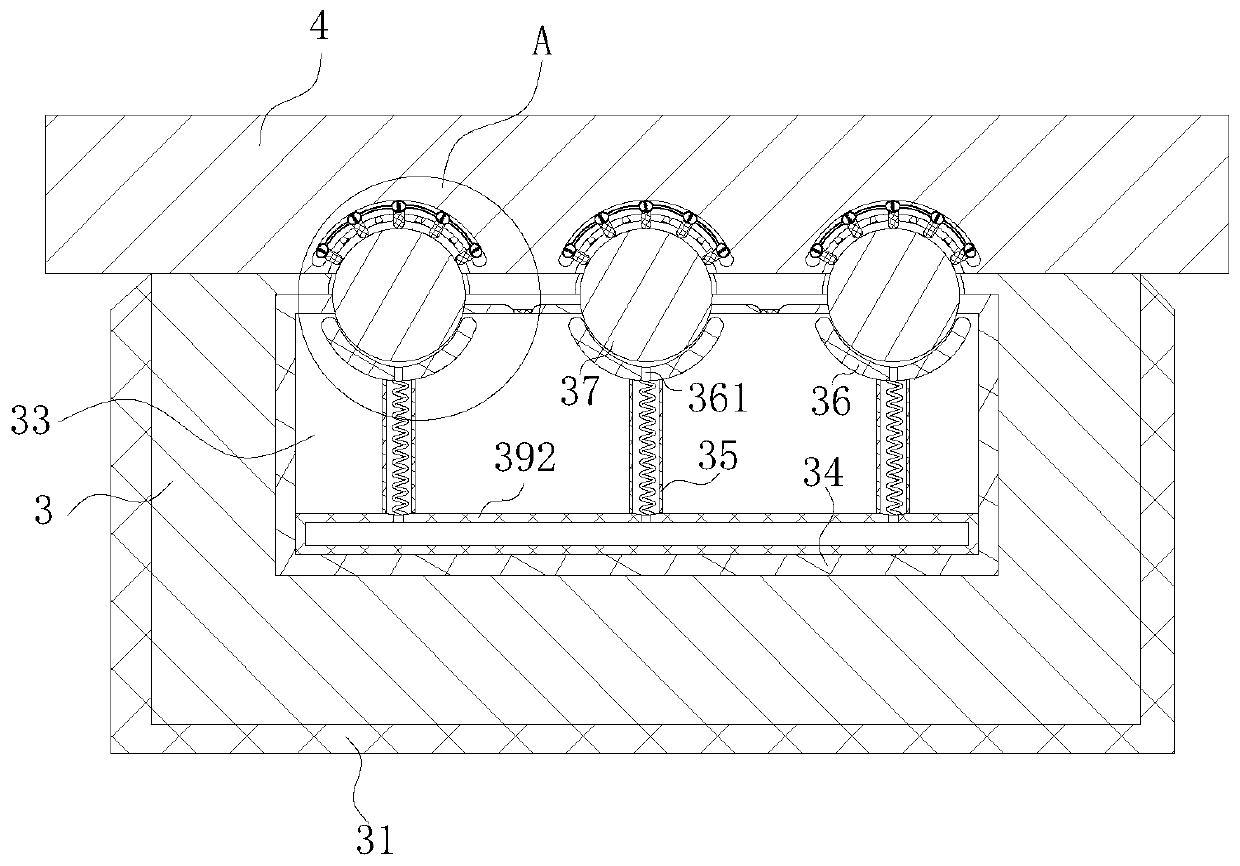

[0021] use Figure 1-Figure 5 A rotor of a three-phase motor according to an embodiment of the present invention is described as follows.

[0022] like Figure 1-Figure 5As shown, a three-phase motor rotor according to the present invention includes a rotor 1, a drive shaft 2, a brush 3 and a slip ring 4; the inner wall of the rotor 1 is fixedly connected with the drive shaft 2 at the centerline position, and The drive shaft 2 is designed to protrude from the rotor 1; the outer surface of the drive shaft 2 is fixedly connected with evenly arranged collector rings 4, and the number of collector rings 4 is two; the outer surfaces of the two collector rings 4 are all slidingly connected There are brushes 3; the outer surfaces of the two brushes 3 are wrapped with an insulating layer 31; the inner walls of the two brushes 3 are fixed with wires 32, and the wires 32 are connected to the power supply through the insulating layer 31; Long grooves 33 are provided in the inner walls ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com