Multi-track magnetic motor and control method thereof

A magnetic motor and permanent magnet technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems that permanent magnets cannot be fully utilized, and the energy of permanent magnet motors cannot be fully converted, so as to avoid the phenomenon of cutting magnetic induction lines, Avoid magnetic flux leakage and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

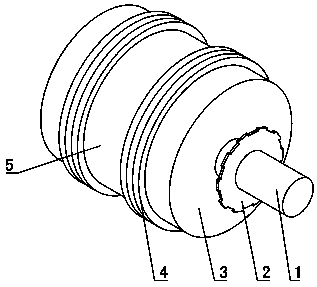

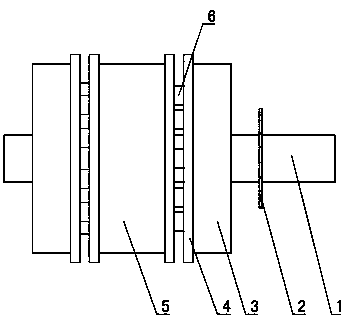

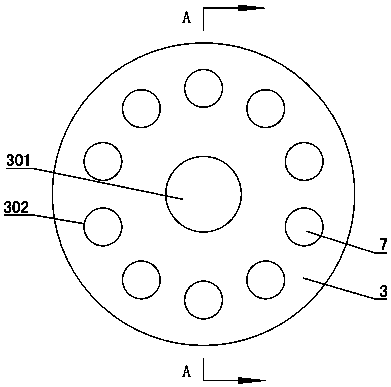

[0044] Such as Figure 1~2As shown: in this embodiment, two stators 4 are provided, and a rotor is arranged symmetrically on both sides of each stator 4, and the permanent magnets 7 on adjacent rotors on both sides of each stator 4 correspond one-to-one, and the two The two opposite permanent magnets 7 on the rotor are coaxially arranged, the polarities of the two opposite permanent magnets 7 on the two rotors are oppositely arranged, and the two rotors arranged between the two stators 4 are integrally arranged, thereby simplifying the motor assembly process. The two stators 4 are coaxially installed in the casing of the motor, the rotor is coaxially installed on the main shaft 1, the main shaft 1 is installed in the casing through the bearing rotation, and the main shaft 1 is coaxially arranged with the casing, and one end of the main shaft 1 Extend out of the casing to form the output shaft of the motor. The phase detection module is arranged between the casing and the mai...

Embodiment 2

[0070] Such as Figure 9 Shown: the difference between embodiment 2 and embodiment 1 is that the cross section of the permanent magnet 7 is fan-shaped. And in this embodiment, there are three stators 4 .

Embodiment 3

[0072] The difference between embodiment 3 and embodiment 1 is that a second mounting plate 5 is arranged between the two stators 4, permanent magnets 7 are embedded in both ends of the second mounting plate 5, and the outer sides of each stator 4 are the same. The shaft is provided with an iron plate, and the diameter of the iron plate is equal to the diameter of the second mounting plate 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com