Washing machine and control method thereof

A washing machine and washing water technology, which is applied to the control device of the washing machine, other washing machines, washing machines with containers, etc., can solve the problems of inconvenient heating of washing water, secondary pollution of clothes, and unfavorable human health, so as to reduce the support structure and Arrangement of connecting cables, improvement of intelligence level, strong expansibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

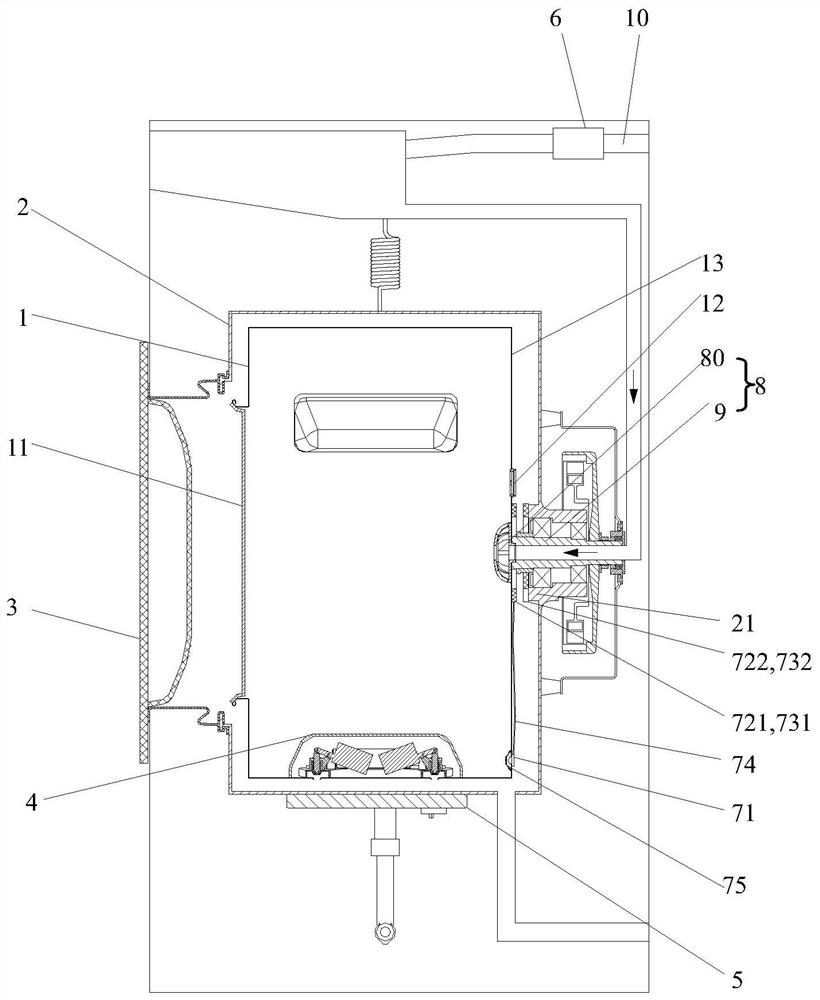

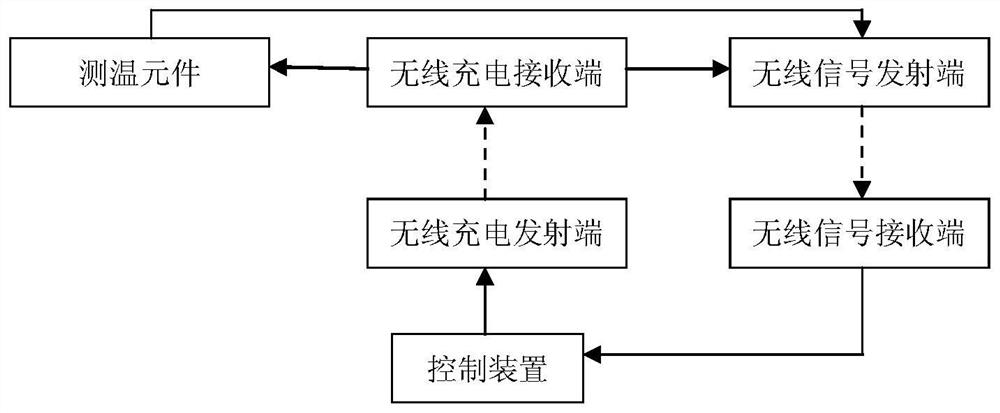

[0074] The washing machine of the present invention includes an inner cylinder 1, which independently holds washing water when washing clothes, avoiding the problems of dirt accumulation and bacterial growth caused by accumulation outside the inner cylinder 1 and overflowing washing water; the central shaft 9 supports and drives the The inner cylinder 1 rotates; the temperature control module is used to control the temperature of the washing water in the inner cylinder 1; the temperature control module includes a temperature measuring element 71 and a power supply for charging the temperature measuring element 71 in a wireless manner Element 73 , the power supply element 73 is arranged close to the central axis 9 . The power supply method adopts wireless power supply, which avoids the possible occurrence of sparks, leakage and other phenomena that may cause harm to users when the wired power supply fails. assembly efficiency.

[0075] Such as figure 1 As shown, it includes a...

Embodiment 2

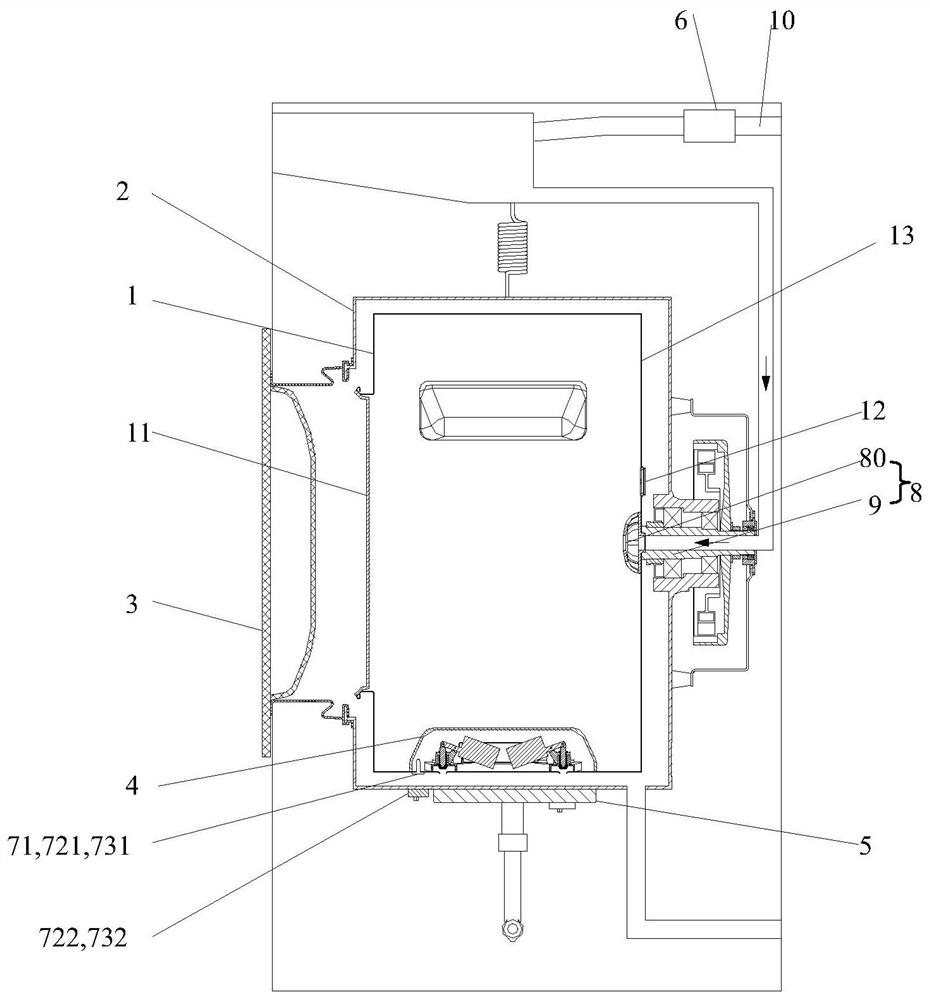

[0104] The main difference between this implementation and the first embodiment is that the installation positions of the temperature measuring devices are different.

[0105] Such as image 3 As shown, the temperature measuring element 71 is arranged in the cavity of the lifting rib 4, and the wireless signal transmitting end 721 and the wireless charging receiving end 731 are respectively spaced from or integrated with the temperature measuring element 71. In the cavity of the lifting rib 4 or arranged on the outer wall surface of the inner tube at the lifting rib 4, the integration of the three improves the modularization level of the washing machine, and the operation is simple during the fault maintenance of the washing machine. The replacement efficiency is improved, and the assembly efficiency of the washing machine is also improved; the interval between the three is set when the washing machine fails, which is conducive to the troubleshooting of the fault. During maint...

Embodiment 3

[0111] The difference between this embodiment and Embodiment 1 and Embodiment 2 is that: the water measuring device 6 adopts a liquid level detection device, and the liquid level detection device uses wireless communication to transmit data.

[0112] Such as Figure 4 As shown, the water measuring device 6 is installed in the cavity of the lifting rib 4, which is the same as the configuration in the temperature measuring device 7, and (not shown in the specific structure diagram) the water measuring device 6 includes a liquid level detection element, a communication A component and a power supply component, the communication component includes a wireless signal transmitter and a wireless signal receiver, and the power supply component includes a wireless charging receiver and a wireless charging transmitter. The wireless charging receiving end provides power supply for the liquid level detection element and the wireless signal transmitting end, and the wireless signal receivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com