Simulation experiment system for staged fracturing or simultaneous fracturing of horizontal wells

A staged fracturing and simulation experiment technology, applied in the field of physical simulation experiments, can solve the problems of being unable to provide effective guidance for mining practice, unable to summarize the law of fracture influence, and unable to study the influence of fracture formation and expansion laws.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

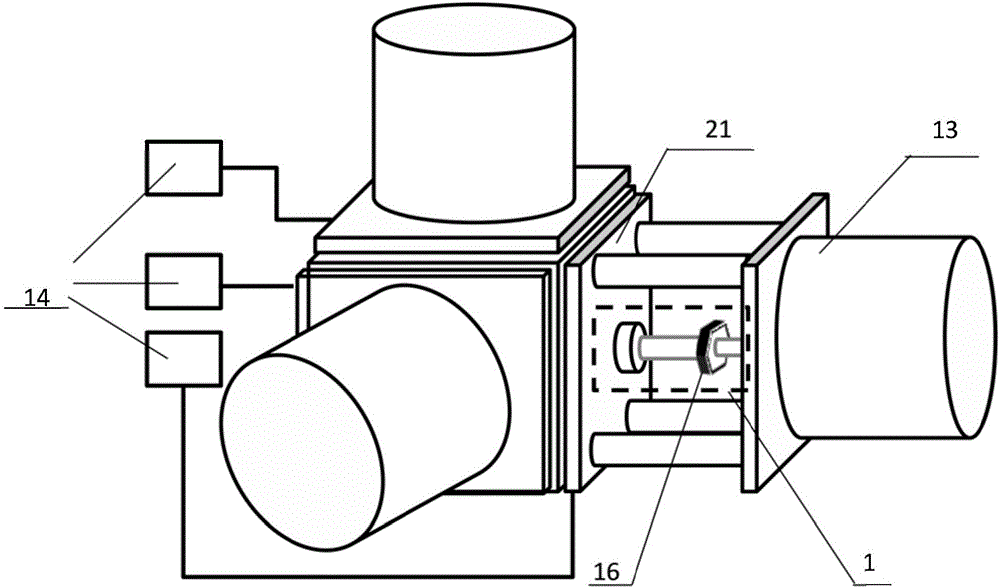

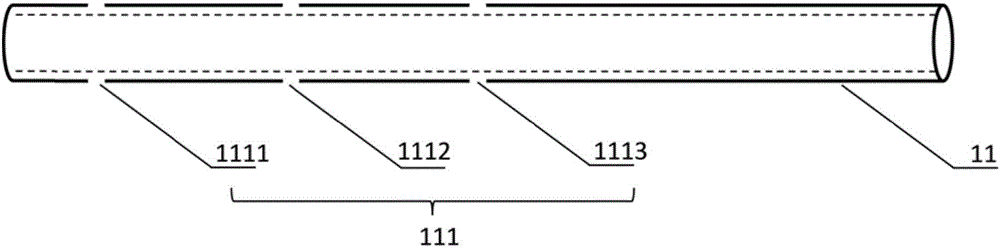

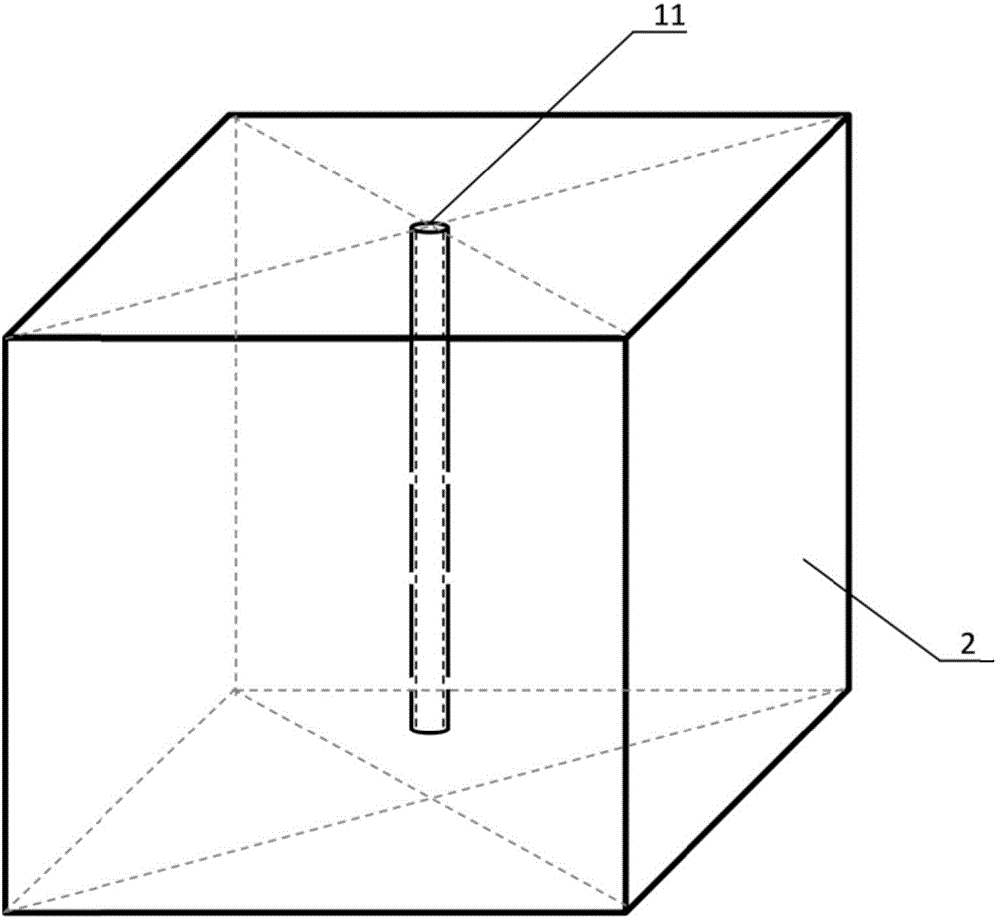

[0049] figure 1 It is a structural schematic diagram of a horizontal well staged fracturing or synchronous fracturing simulation experiment system provided by the present invention, figure 2 It is a structural schematic diagram of the simulated wellbore of the horizontal well staged fracturing or synchronous fracturing simulation experiment system provided by the present invention, image 3 It is a schematic structural diagram of the simulated wellbore and artificial rock samples of the horizontal well staged fracturing or simultaneous fracturing simulation experiment system provided by the present invention, Figure 4 It is a structural schematic diagram of the liquid injection pipe of the horizontal well staged fracturing or simultaneous fracturing simulation experiment system provided by the present invention, Figure 5 It is a structural schematic diagram of the position adjustment device of the horizontal well staged fracturing or synchronous fracturing simulation exper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com