Ultra-precise processing integrated platform for large caliber optical mirror surface

A technology for ultra-precision processing and optical mirrors, which is applied in the direction of optical surface grinders, metal processing equipment, manufacturing tools, etc., can solve the problems of limitations, poor system rigidity, and reduce the manufacturing accuracy and efficiency of large-diameter optical mirrors, so as to avoid repeated installation The effect of unloading, eliminating errors and effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

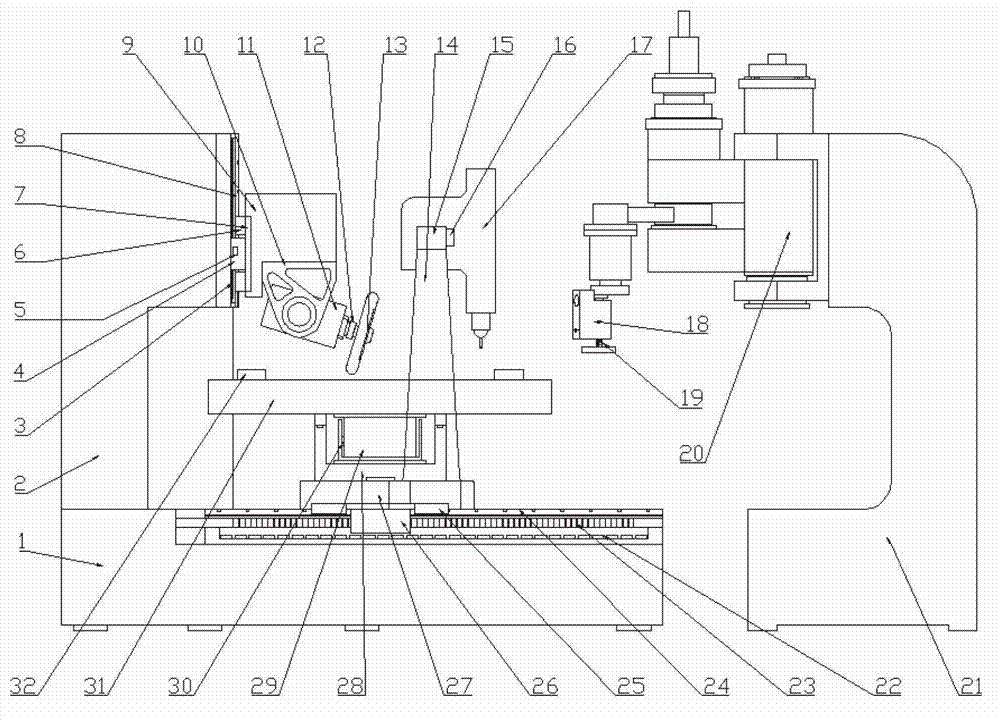

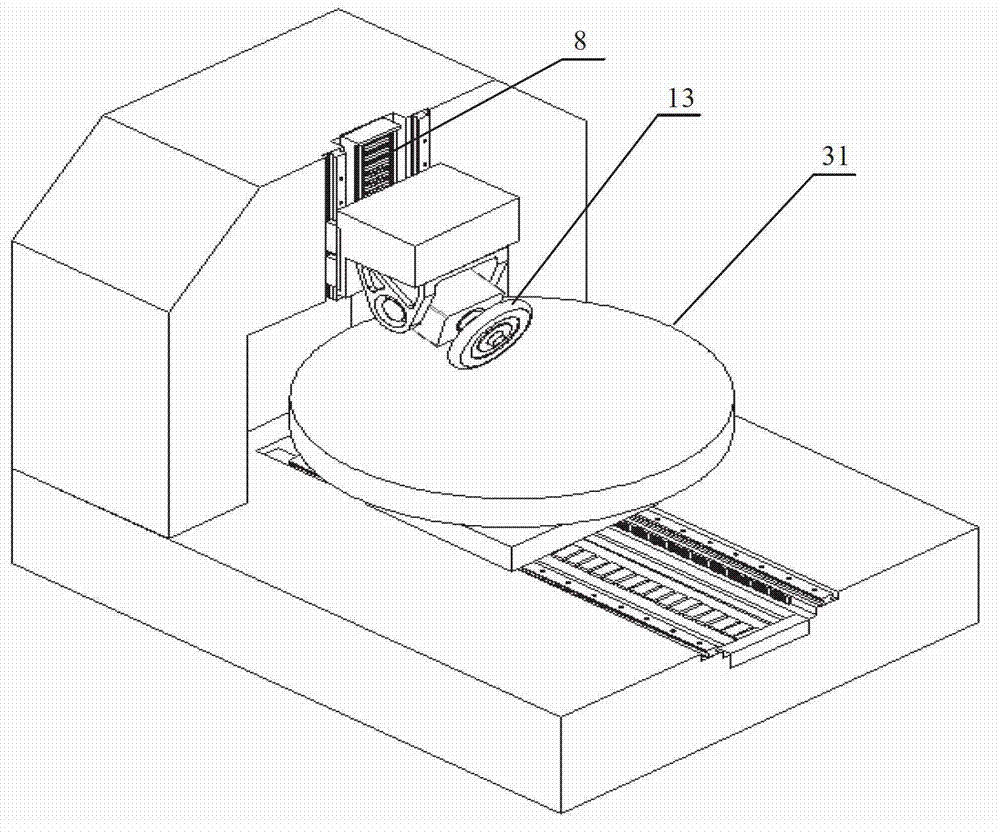

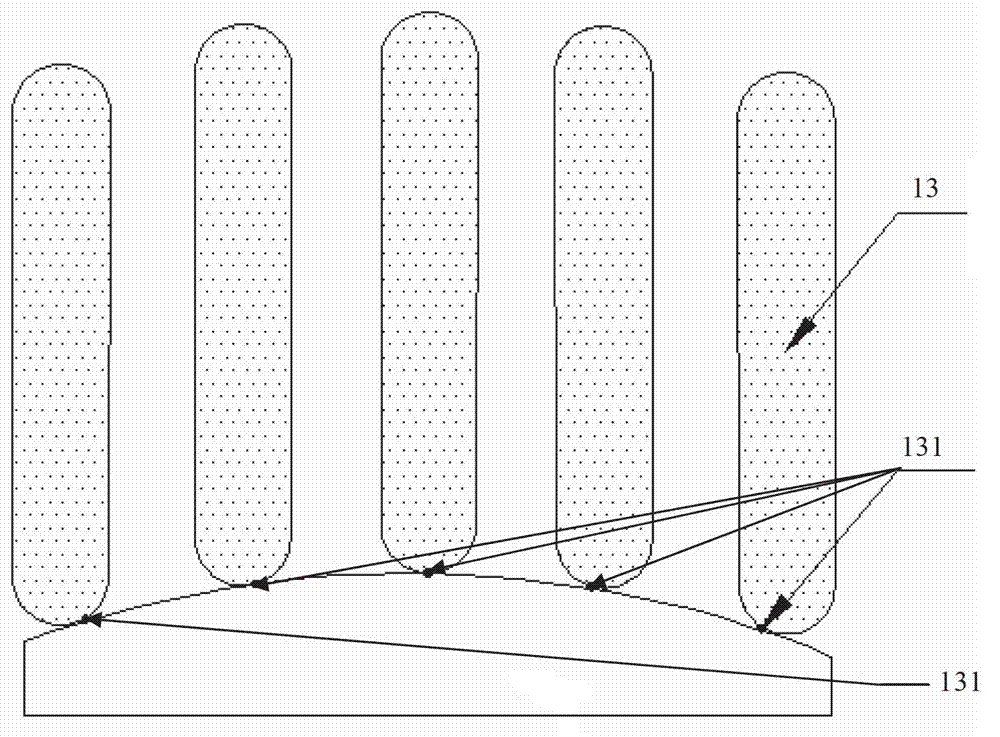

[0021] like Figure 1-3 As shown, the integrated platform for ultra-precision processing of large-diameter optical mirrors of the present invention includes: a base 1, a horizontal moving device, a rotating device, an ultra-precision grinding device, a mirror detection device and a grinding device. Wherein, the horizontal moving device is arranged on the base 1, and the rotating device is arranged on the horizontal moving device.

[0022] The horizontal moving device includes: a horizontal linear guide rail 24 , a horizontal linear motor 22 , a horizontal grating ruler 23 , and a horizontal moving workbench 27 . The horizontal linear motor 22 is fixedly arranged on the base 1, the horizontal linear guide rail 24 is fixedly arranged on the base 1, and the bottom of the horizontal moving workbench 27 is respectively connected with the horizontal linear motor slider 26 and the horizontal linear guide rail slider 25, which can be moved along the horizontal linear guide rail. 24 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com