Recovery process and device for synthetic fiber waste

A synthetic fiber and recovery device technology, applied in the field of synthetic fiber resource recovery technology, can solve problems such as environmental pollution, post-processing and recovery difficulties, waste, etc., and achieve the effects of simplified process flow, high degree of automation, and water reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

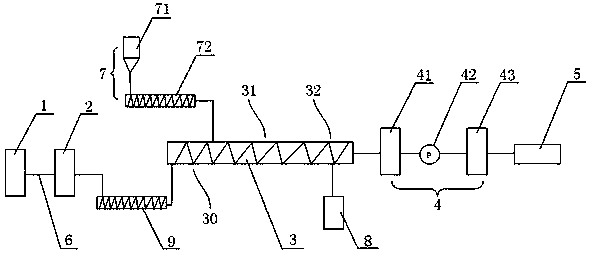

[0057] Embodiment 1: A kind of recycling process of synthetic fiber waste.

[0058] The following takes the recycling of polyester industrial yarn waste as an example to further illustrate the present invention. Using the recycling process of the present invention, other synthetic fiber waste such as nylon and polypropylene waste silk, waste melt, waste blocks, etc. can also be recycled.

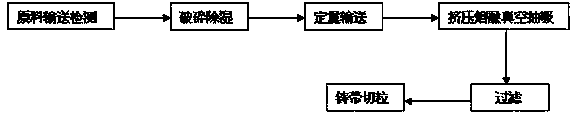

[0059] Such as figure 1 As shown, the recovery process of a synthetic fiber waste of the present invention includes waste detection - crushing and dehumidification - extrusion melting - filtration - casting belt pelletizing.

[0060] 1. Waste detection:

[0061] Pass the polyester industrial yarn waste through the metal detector to remove the metal impurities in the waste, and transport the waste without metal impurities to the crusher for crushing;

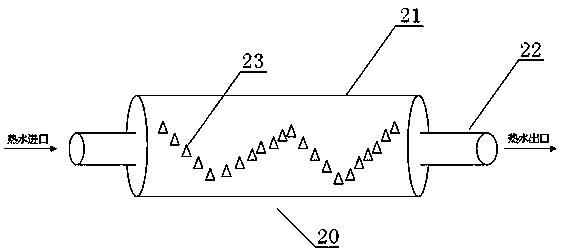

[0062] 2. Crushing and dehumidification:

[0063] The detected waste is sent to the crusher for crushing, and heated and dehumidified. The ...

Embodiment 2

[0077] The production process is the same as in Example 1, the difference is that in the crushing and dehumidification process of step 2, only the waste materials are crushed, and the hollow hob heated by the water bath is not used for heating and dehumidification. The details are as follows: send the detected waste materials into the crusher After crushing, the waste is crushed into powders with a length of 1-50mm.

[0078]

Embodiment 3

[0080] The production process is the same as in Example 1, the difference is that the filtration process only adopts one-stage filtration, the precision of the one-stage filtration is 30-60 microns, and the filtration temperature is controlled at 270-290°C. After the melt passes through one-stage filtration, the Sent to cast strips for cutting pellets.

[0081]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com