Concrete prefabricated part making method

A technology for concrete prefabricated parts and a production method, which is applied to manufacturing tools, ceramic molding machines, etc., can solve the problems of manpower and material resources, complicated operation and maintenance work, and inability to realize factory production of concrete prefabricated parts, etc., and achieves simple and fast operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

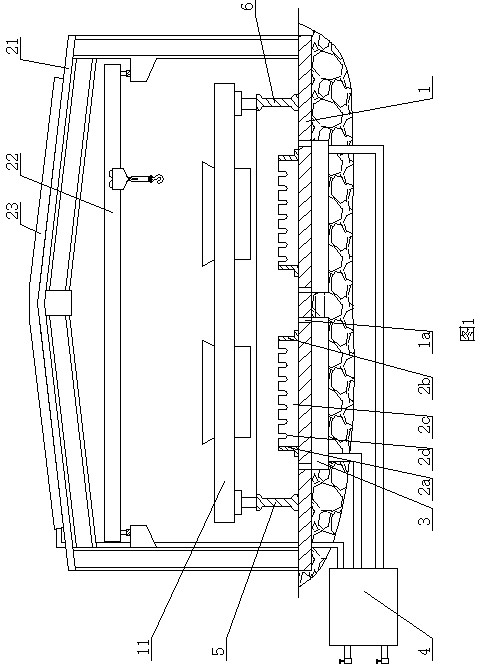

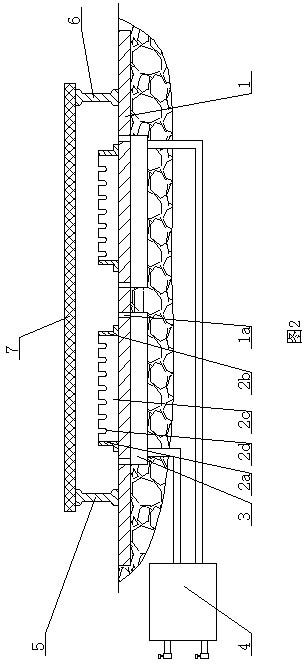

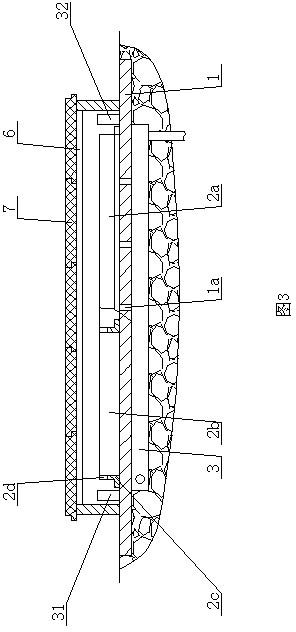

[0047] The technical solution of the present invention will be described in detail with reference to the accompanying drawings and embodiments.

[0048] A kind of preparation method of concrete prefabricated part of the present invention, comprises the following steps:

[0049] (1) Preparation of concrete for use;

[0050] (2) Making the pool: set up a platform 1 in the factory building 21, install the front wall and the rear wall on the front and rear of the upper surface of the platform 1 respectively, and install the first steel rail 5 on the left and right parts of the upper surface of the platform 1 respectively and the second rail 6, the front wall and the rear wall are connected with the first rail 5 and the second rail 6 respectively to form a pool;

[0051] (3) Layout equipment: the concrete placing machine 11 is installed on the first rail 5 and the second rail 6 in step (2), the bridge crane 22 is set on the upper part of the concrete placing machine 11, and the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com