Railway engineering machine hybrid power source system

A power source system, railway engineering technology, applied in electric traction, electric vehicle, AC induction motor traction, etc., can solve the problems of environmental pollution, complex maintenance of internal combustion hydraulic power mode, hydraulic oil leakage, etc., to shorten the conversion time , Improve work efficiency and reduce workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

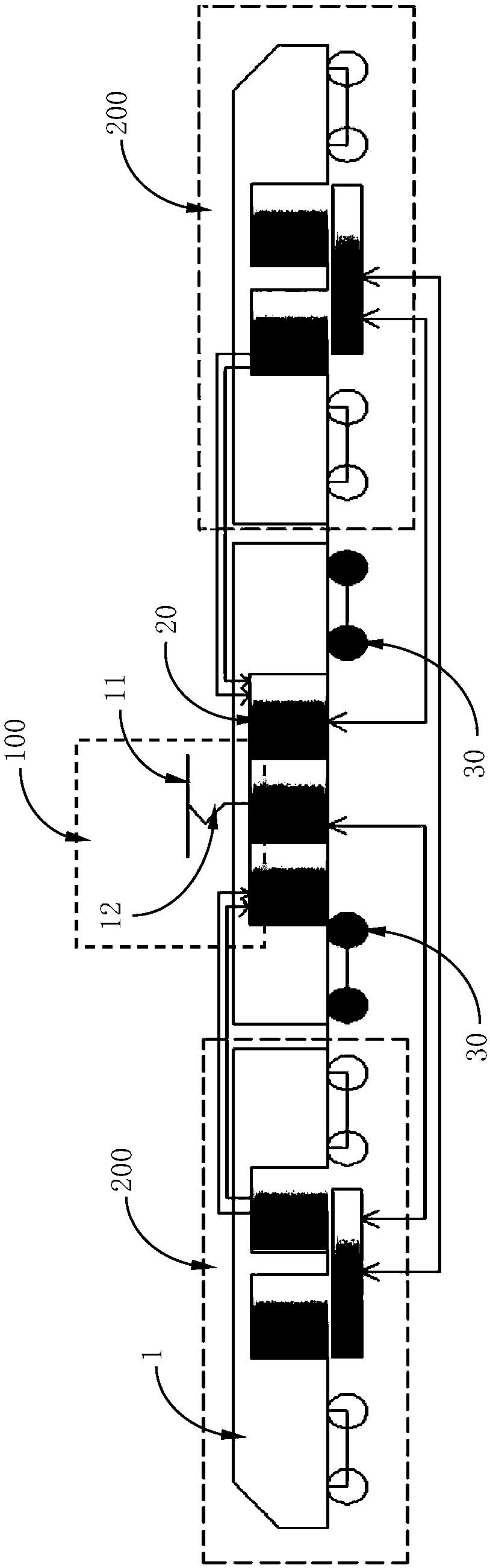

[0036] as attached figure 1As shown, a specific embodiment of a railway engineering machinery hybrid power source system includes: a hybrid power source 10, and a converter 20 connected to the hybrid power source 10, and the hybrid power source 10 is used for the whole vehicle through the converter 20 Electrical equipment (including traction, brake air compressor, hydraulic pump voltage, traction motor 30, etc.) power supply. The hybrid power source 10 further includes a main power source 100 and an auxiliary power source 200. The electric energy from the main power source 100 or the auxiliary power source 200 is converted and processed by the converter 20 and then converted into the electric energy required by the electrical equipment of the vehicle. In this embodiment, the railway engineering machinery 1 is equipped with a catenary power source and an auxiliary power source (such as a supercapacitor 15 or a storage battery pack 17) 100. After electric energy conversion and c...

Embodiment 2

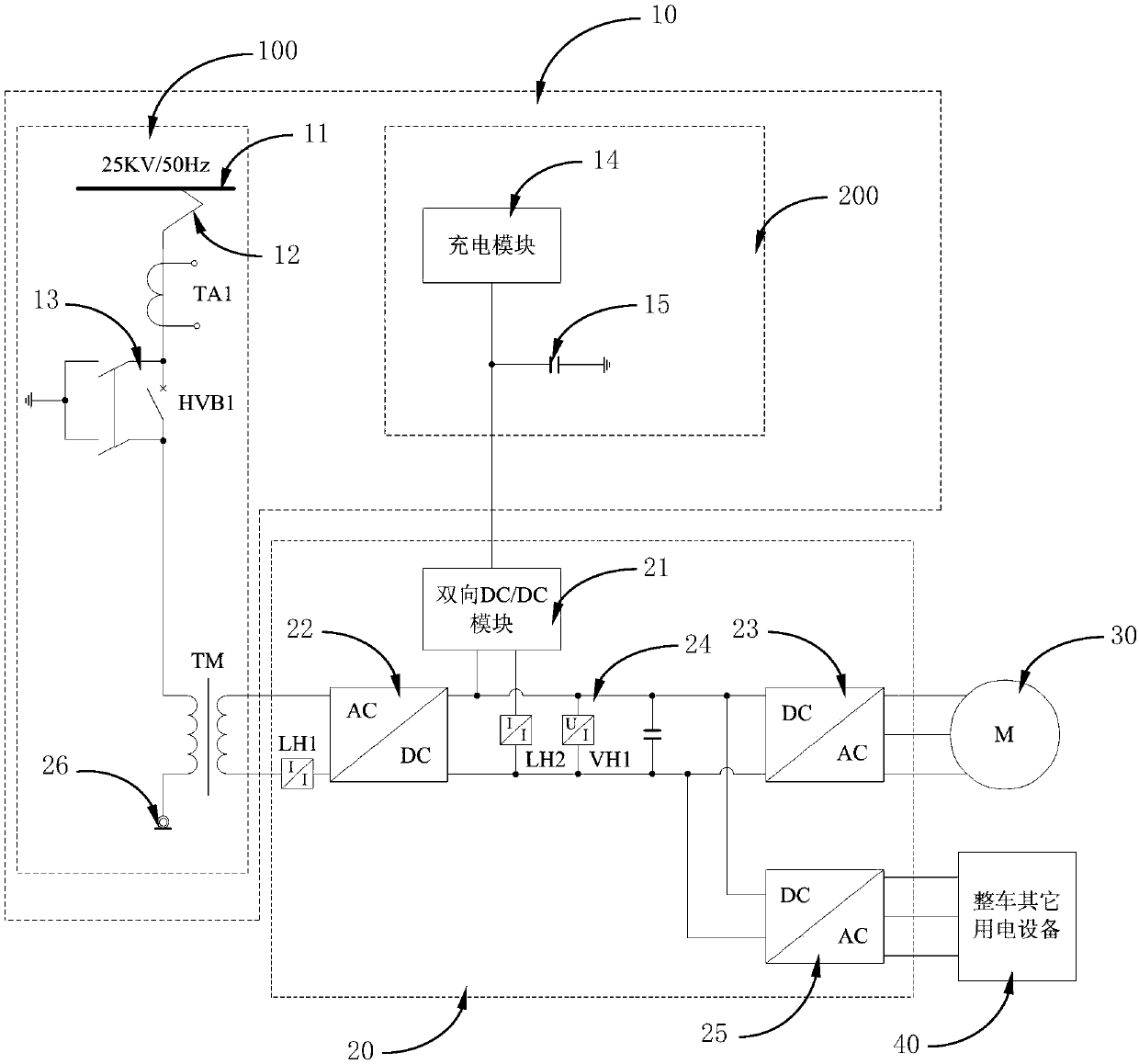

[0039] as attached figure 2 As shown, on the basis of Embodiment 1, the auxiliary power source 200 is further a supercapacitor power source. When the electrical connection between the railway engineering machinery 1 and the catenary 11 is disconnected, or the catenary 11 cannot continue to supply power, the supercapacitor is used The power source supplies power to the electrical equipment of the vehicle. When it is necessary to switch between the two power sources, the catenary power source and the supercapacitor power source supply power to the electrical equipment of the vehicle at the same time during the switching process. The main circuit of catenary power plus supercapacitor hybrid power source includes two modes of catenary power supply and supercapacitor power supply. It takes power from catenary 11 or supercapacitor 15, and supplies power to traction motor 30 after a series of transformations. Among them, the supercapacitor 15 has various advantages such as small si...

Embodiment 3

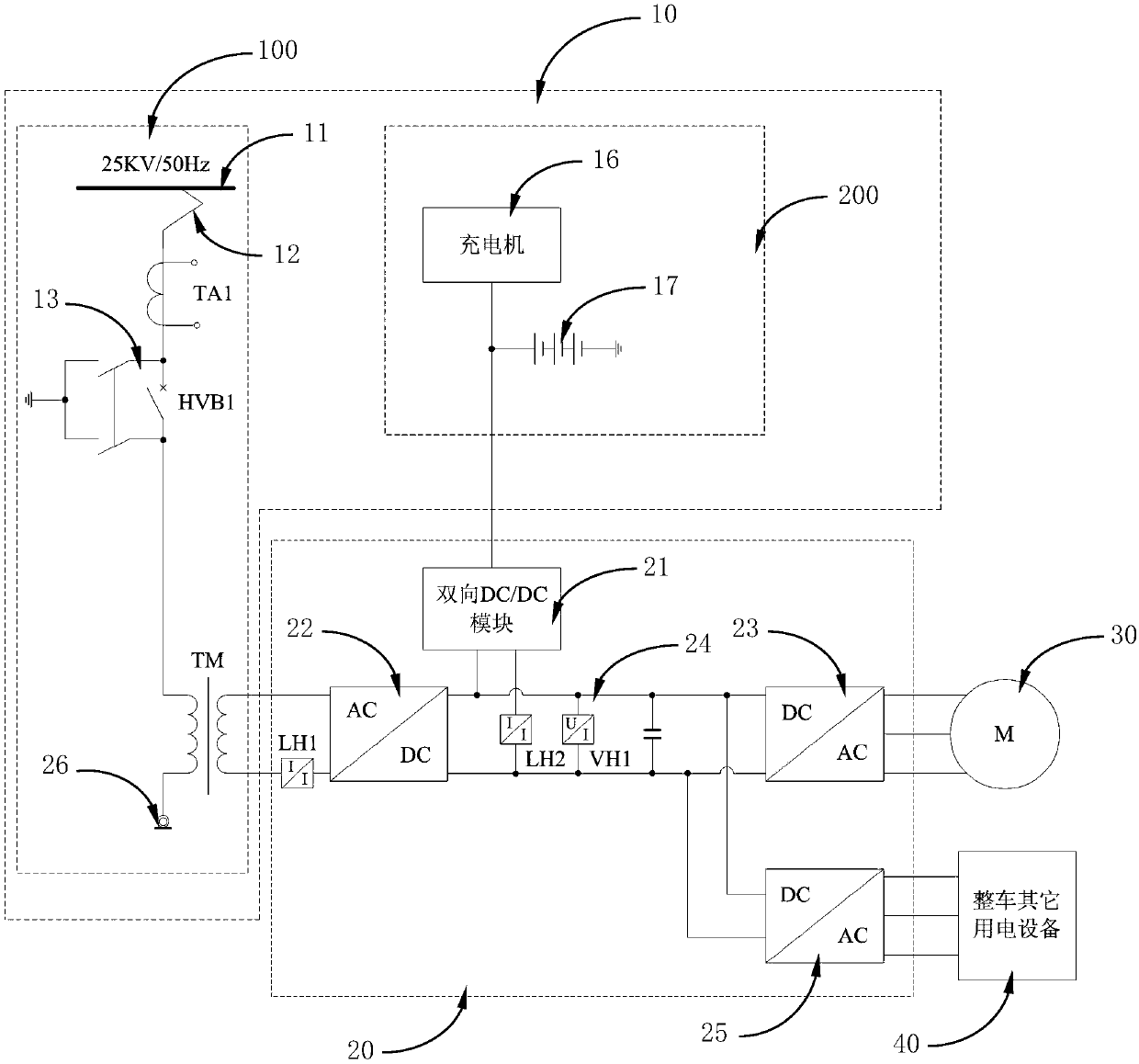

[0045] as attached image 3 As shown, on the basis of Embodiment 1, the auxiliary power source 200 is further a battery pack power source. When the electrical connection between the railway engineering machinery 1 and the catenary 11 is disconnected, or the catenary 11 cannot continuously supply power, the battery pack is used The power source supplies power to the electrical equipment of the whole vehicle, and the storage battery pack 17 can adopt a lithium battery pack. When it is necessary to switch between the two power sources, the catenary power source and the battery pack power source supply power to the electric equipment of the whole vehicle at the same time during the switching process. The main circuit of the catenary power plus battery hybrid power source includes two modes of catenary power supply and battery power supply. It takes power from the catenary 11 or the battery pack 17, and supplies power to the traction motor 30 after a series of transformations. Amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com