Method for inhibiting degradation of decarburization amine absorbent

An absorbent and decarburized amine technology, which is applied in the direction of absorption, separation methods, chemical instruments and methods, etc., to achieve the effects of ensuring stability, less addition, and significant antioxidant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

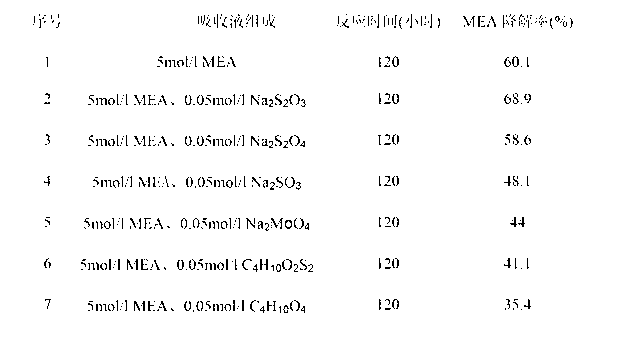

Embodiment 1

[0019] Select the ethanolamine aqueous solution of 5mol / l (massfraction about 30%), add two kinds of typical antioxidant threitol (C 4 h 10 o 4 ) and 2-thiothreitol (C 4 h 10 o 2 S 2 ) in a reactor with a reaction temperature of 120°C and an oxygen partial pressure of 0.25Mpa for a 120h enhanced degradation test, and the common antioxidant sodium sulfite (Na 2 SO 3 ) and sodium molybdate (Na 2 MoO 4 ) for comparison, and the degradation rate of ethanolamine (MEA) was used as an index to evaluate the antioxidant effect. The experimental results are shown in Table 1. It can be seen from Table 1 that the antioxidant effects of 2-thiothreitol and threitol increased by 58.3% and 105.8% respectively compared with sodium sulfite, and increased by 18.0% and 53.4% respectively compared with sodium molybdate. Sodium dithionite (Na 2 S 2 o 4 ) and sodium thiosulfate (Na 2 S 2 o 3 ) has almost no antioxidant effect.

[0020] Table 1. Antioxidant test results of different...

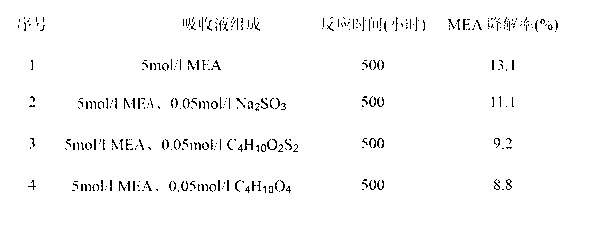

Embodiment 2

[0025] Select the ethanolamine aqueous solution of 5mol / l, add two kinds of typical antioxidant threitol (C 4 h 10 o 4 ) and 2-thiothreitol (C 4 h 10 o 2 S 2 ) in a reaction kettle with a reaction temperature of 55°C and an oxygen partial pressure of 0.1Mpa to perform a 500h enhanced degradation test, the results are shown in Table 2. It can be seen from Table 2 that the antioxidant effects of threitol and 2-thiothreitol are respectively increased by 94.1% and 114.5% compared with sodium sulfite.

[0026] Table 2. Antioxidant test results of different additives

[0027]

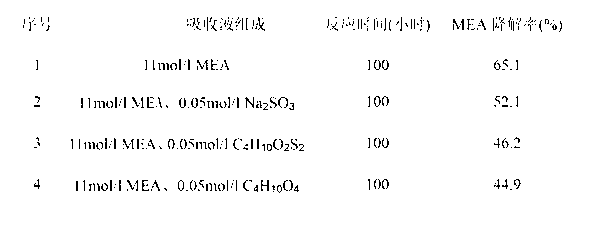

Embodiment 3

[0029] Select the ethanolamine aqueous solution of 11mol / l (massfraction about 70%), add two kinds of typical antioxidant threitol (C 4 h 10 o 4 ) and 2-thiothreitol (C 4 h 10 o 2 S 2 ) in a reaction kettle with a reaction temperature of 150°C and an oxygen partial pressure of 0.35Mpa to perform a 100h enhanced degradation test. The experimental results are shown in Table 3. It can be seen from Table 3 that the antioxidant effects of threitol and 2-thiothreitol are respectively increased by 45.1% and 55.2% compared with sodium sulfite.

[0030] Table 3. Antioxidant test results of different additives

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com