Method for cleaning container inner wall and cleaner thereof

A technology for cleaning inner walls and containers, applied in cleaning methods and appliances, chemical instruments and methods, and cleaning hollow objects, etc., can solve problems such as unsatisfactory cleaning effect, high power consumption, and water pollution, and achieve ideal cleaning effect, Low maintenance cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

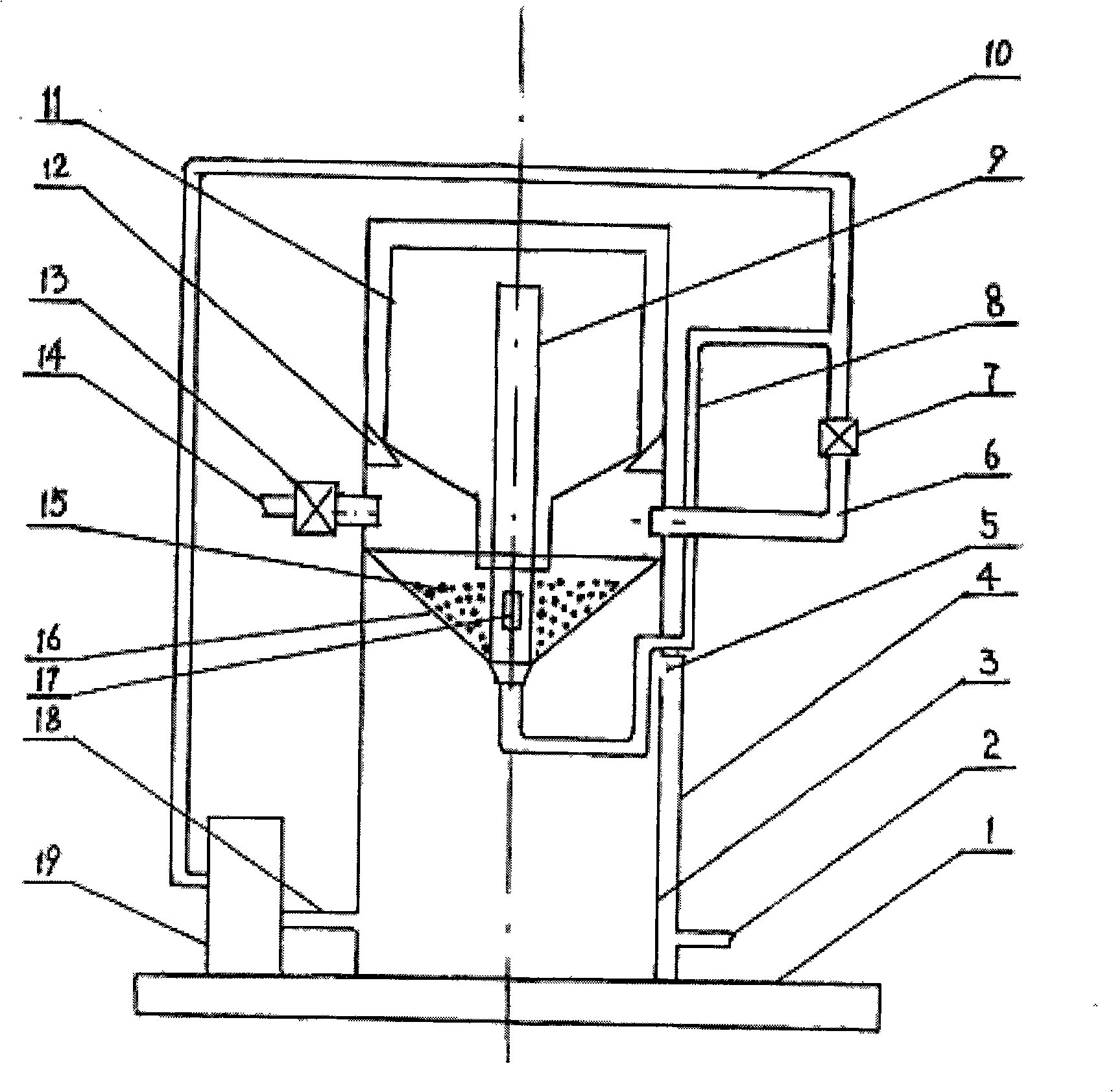

[0014] The present invention will be further described below in conjunction with the accompanying drawings and examples.

[0015] The following are specific examples of the cleaning method for the inner wall of the container.

[0016] Use high-speed water flow to carry spherical particles to wash and clean the inner wall of the container; during operation, the opening of the container is downward, and the spherical particles will continue to participate in cleaning after falling back with the water and leaving the container, so as to realize the recycling of spherical particles;

[0017] Wherein, the high-speed water flow is provided by a water pump; the spherical particles are made of ceramic material with a diameter of 2-3mm.

[0018] The following are specific examples of the container inner wall cleaning device.

[0019] Such as figure 1 As shown, this example includes a machine base 1 , a fuselage 3 whose bottom end is fixedly installed on the machine base 1 , and a wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com