Silane compound modified SiO anode material as well as preparation method and application thereof

A technology of silane compound and negative electrode material, applied in battery electrodes, electrical components, circuits, etc., can solve the problem of fast capacity decay, achieve the effect of inhibiting swelling and pulverization, improving cycle performance, and facilitating commercialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

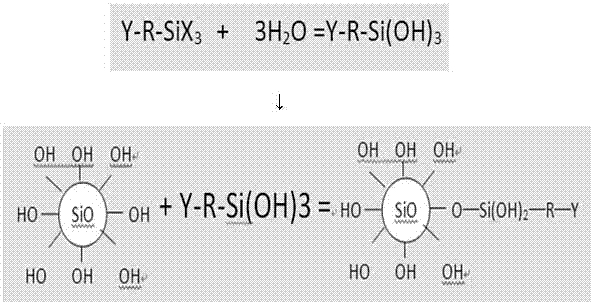

Method used

Image

Examples

Embodiment 1

[0034] Hydrolyze 0.15g of γ-aminopropyltriethoxysilane in water, drop a small amount of oxalic acid to make it weakly acidic; put 5g of SiO in a mixture of 60mL of ethanol and water (ethanol: water = 5:1) for 30min, It is then blended with hydrolyzed γ-(methacryloyloxy)propyltrimethoxysilane. Inert gas is introduced, and the flow rate is controlled at 100~300 mL / min (the flow rate is too small to ensure the inert atmosphere of the internal reaction, and the air flow is too large, which is easy to splash the liquid.), and the reaction is carried out by magnetic stirring at 80°C under the reflux device for 6 hours. Dry at 80° C. for 12 hours to obtain a SiO material with a modified layer of γ-aminopropyltriethoxysilane.

[0035] After being modified by γ-aminopropyltriethoxysilane, its initial charge specific capacity is 1272.99mAh / g, and its initial efficiency is 75.11%; after 100 cycles, its charge specific capacity is 934.37mAh / g, and its capacity retention rate is 73.39% %....

Embodiment 2

[0037] Hydrolyze 0.15g of vinyltriethoxysilane in water, drop a small amount of oxalic acid to make it weakly acidic; put 5g of SiO in a mixture of 60mL of ethanol and water (ethanol: water = 5:1) for 30min, and then mix with Hydrolyzed γ-(methacryloyloxy)propyltrimethoxysilane blended. Inert gas was introduced, the flow rate was controlled at 100-300 mL / min, the reaction was carried out under magnetic stirring at 80°C for 6h under reflux device, and the SiO material with vinyltriethoxysilane modified layer was obtained by drying at 80°C for 12h.

[0038] After being modified by vinyltriethoxysilane, its initial charge specific capacity is 1388.56mAh / g, and its initial efficiency is 78.13%; after 100 cycles, its charge specific capacity is 1030.04mAh / g, and its capacity retention rate is 74.18%.

Embodiment 3

[0040]Hydrolyze 0.15g of γ-glycidyl etheroxypropyltrimethoxysilane in water, add a small amount of oxalic acid dropwise to make it weakly acidic; put 5g of SiO in a mixture of 60mL ethanol and water (ethanol: water = 5:1) ultrasonically 30min, and then blended with hydrolyzed γ-(methacryloyloxy)propyltrimethoxysilane. Inert gas was introduced, the flow rate was controlled at 100-300 mL / min, and the reaction was carried out under a reflux device with magnetic stirring at 80°C for 6h, and dried at 80°C for 12h to obtain a SiO material with a modified layer of γ-glycidyl etheroxypropyltrimethoxysilane.

[0041] After being modified by γ-glycidyl etheroxypropyl trimethoxysilane, its initial charge specific capacity is 1267.02mAh / g, and its initial efficiency is 74.18%; after 100 cycles, its charge specific capacity is 899.22mAh / g, and the capacity retention rate It was 70.97%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com