Product production process computer simulation system and method

A technology of production process flow and computer simulation, applied in the direction of calculation, instrumentation, data processing applications, etc., can solve problems such as inability to simulate or optimize product process routes, and achieve the effect of optimizing product production process routes and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

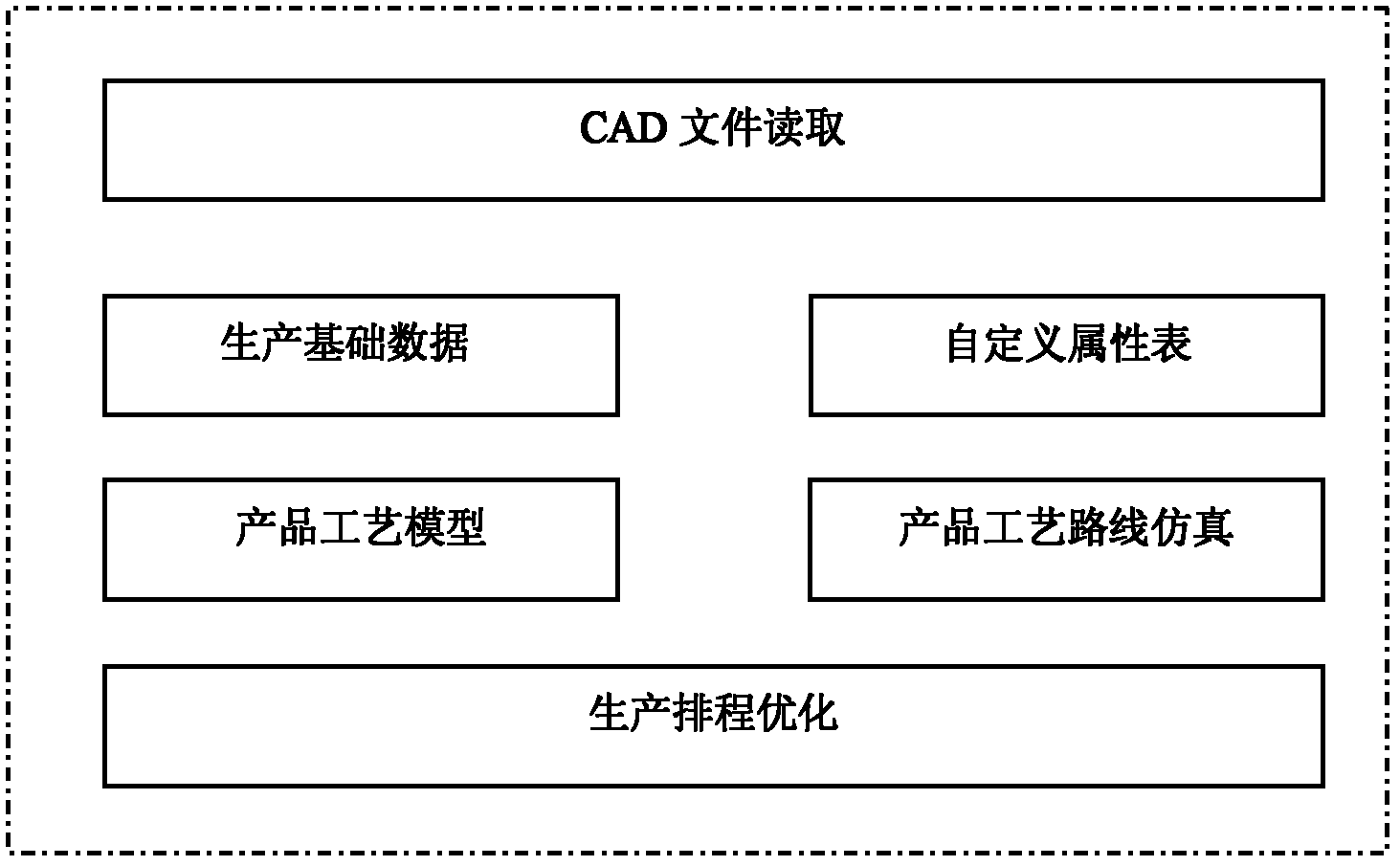

[0059] like figure 1 As shown, the present invention provides a computer simulation system for product production process. The system includes a file reading module, a basic data module, a custom attribute module, a product process model module, a route simulation module and a production scheduling optimization module.

[0060] The following is a detailed description of the work and composition of each module of the system:

[0061] 1. File reading module

[0062] The file reading module is used to read the data of the product design system and put it into the product process model module.

[0063] 2. Basic data module

[0064] The basic data module is used to set the status data of the production site.

[0065] The basic data module includes material management unit, machining center unit, shift management unit, process type unit and tooling mold unit, among which,

[0066] The material management unit is used to manage the basic material data and material attributes. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com