Application process of Ti microalloying in 400MPa-grade steel bar production

A technology of micro-alloying and grade steel bars, applied in the field of metallurgy, can solve the problems of precipitation strengthening, fluctuation of chemical composition, fluctuation of product performance, etc., and achieve the effects of mature production technology, stable product quality, and reduced product production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

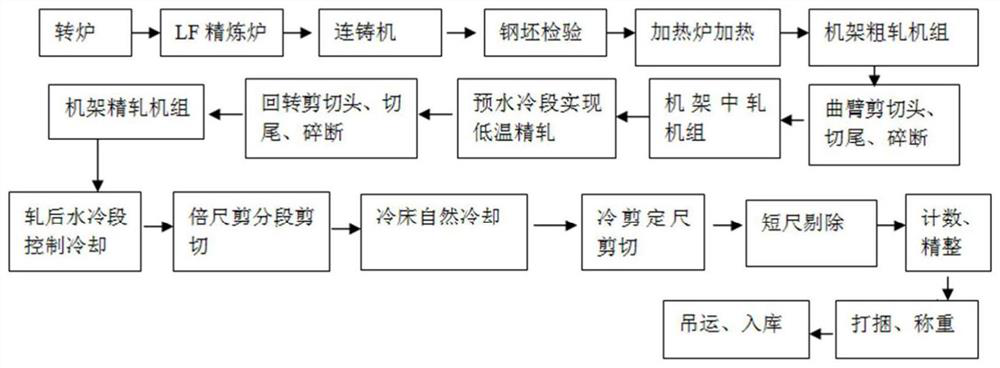

[0034] In this embodiment, steel bars with two specifications of 22mm and 16mm are produced, and the production process is based on the instructions figure 1 The process route, where the process parameters are:

[0035] (1) The tapping temperature of molten steel is controlled above 1630°C;

[0036] (2) The titanium wire is fed 2 to 3 minutes before the argon blowing station, and the mass percentage is controlled within the range of 0.020% to 0.050%;

[0037] (3) Continuous casting superheat control 20-35 ℃;

[0038] (4) Steel rolling temperature parameters:

[0039] Heating furnace temperature control: preheating section 680-980°C, heating section 900-1080°C, heating section 1060-1180°C, soaking section 1090-1180°C;

[0040] The rolling temperature is 1050-1100℃;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com