Platinum-modified indium-based oxide catalyst as well as preparation method and application thereof

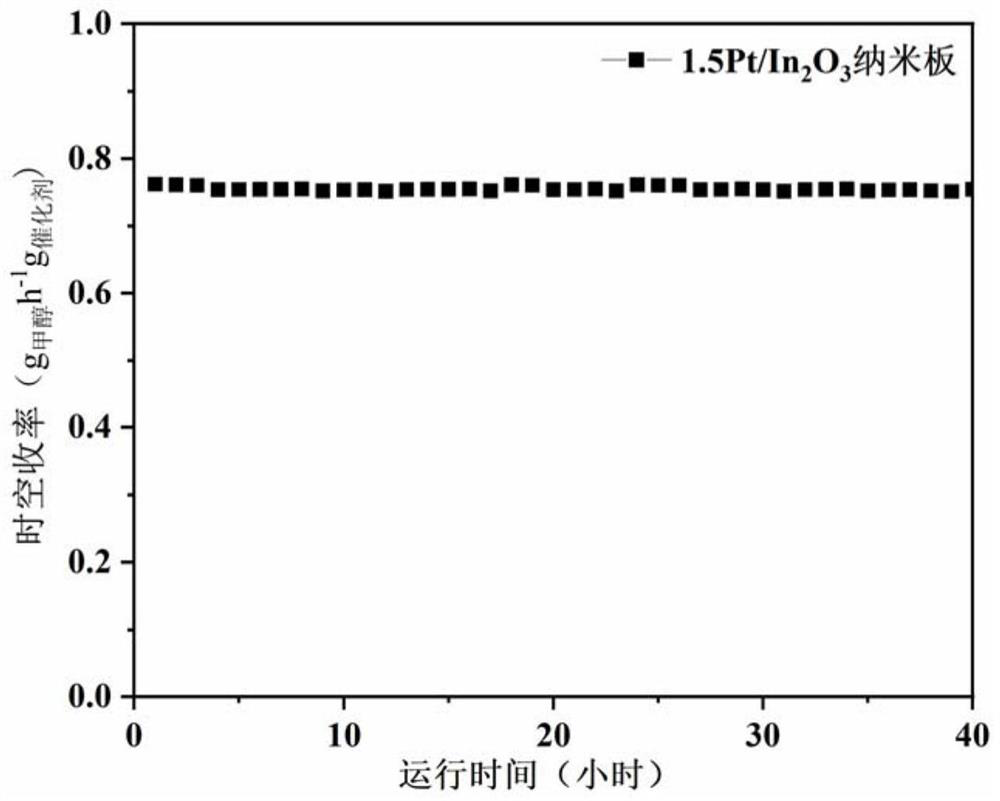

A catalyst and oxide technology, which is applied in the field of catalyst technology and energy chemical industry, can solve the problems of poor catalytic activity and stability of indium-based catalysts, harsh reaction conditions of indium-based catalysts, unsatisfactory catalytic activity, etc., and achieve good application prospects, Excellent catalytic performance, low requirement for reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] A method for preparing a platinum-modified indium-based oxide catalyst. The indium salt is indium nitrate tetrahydrate, the precipitating agent is urea, and the platinum precursor is chloroplatinic acid. The method comprises the following steps:

[0047] (1) Preparation of plate-like In 2 o 3 Carrier:

[0048] After mixing water and alcohol, solution 1 is obtained, and indium salt is dissolved in solution 1 to obtain solution 2;

[0049] In addition, water and alcohol are mixed to obtain solution 3, and then the precipitating agent is dissolved in solution 3 to obtain solution 4;

[0050] Under stirring state, solution 4 is added in solution 2, after stirring, carry out hydrothermal reaction; During hydrothermal reaction, the mass ratio of indium salt and precipitation agent is (4-5): 4; The volume ratio of ethanol and water For (2-6): 1; the temperature of hydrothermal reaction is 115-125 ℃, and the time is 16-18h;

[0051] After the reaction, the resulting precipi...

Embodiment 1

[0059] Preparation of indium oxide by hydrothermal method: Take 32mL of ethanol and 5mL of deionized water to make solution 1. Dissolve 4.07g of indium nitrate tetrahydrate into the above solution 1 to form solution 2. Take another 20mL of ethanol and 5mL of deionized water to make solution 3. 4.0 g of urea was dissolved in the above-mentioned solution 3 to form solution 4. Under vigorous stirring, solution 4 was added to solution 2 and stirring was continued at room temperature for 2 hours. Then the solution was taken out and put into a reaction kettle, and kept at 120° C. for 17 hours. After the reaction, the sample was taken out and washed several times with deionized water, dried at 60° C. for 12 hours, and calcined at 300° C. for 5 hours to obtain plate-shaped indium oxide.

Embodiment 2

[0061] 5 g of indium nitrate tetrahydrate was calcined at 300° C. for 5 hours to obtain amorphous indium oxide nanoparticles.

[0062] It can be seen that the adjustment of the morphology of indium oxide requires special reaction conditions. In this application, indium nitrate is used as the precursor, and by adjusting the ratio of water and alcohol in the solvent, the specific morphology is obtained by hydrothermal method at high temperature and high pressure. Indium oxide, while the hydrothermal method is often used for shape adjustment in the preparation of traditional catalysts, that is, in a sealed pressure vessel, water or alcohol is used as a solvent, and the powder is dissolved and recrystallized. The preparation method of the material.

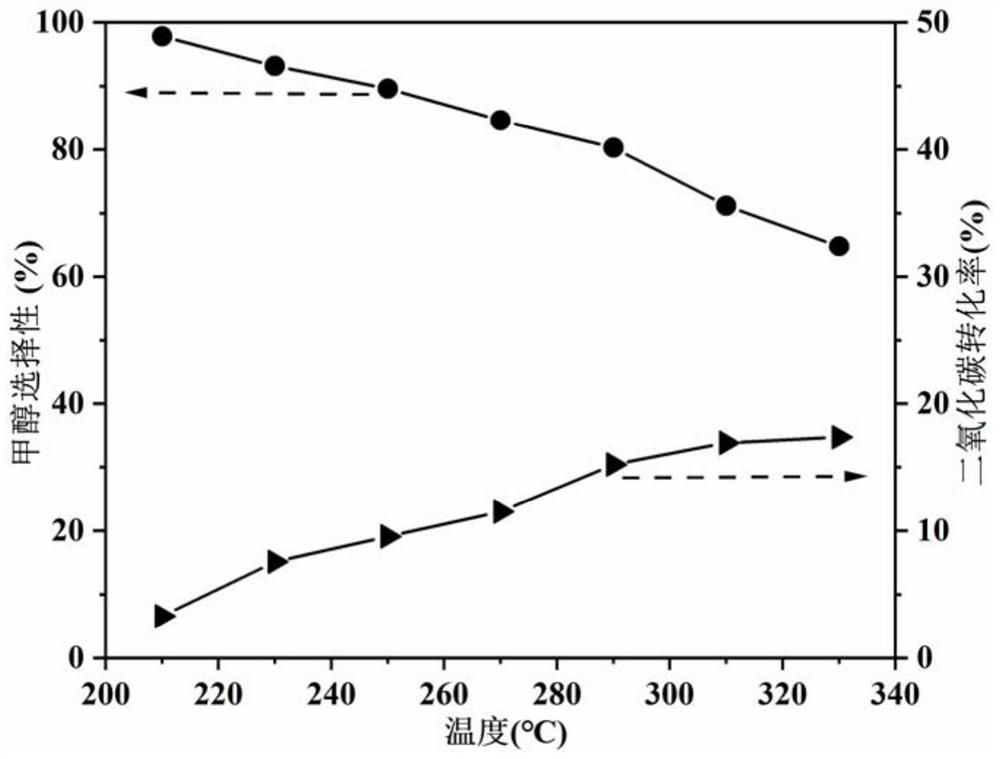

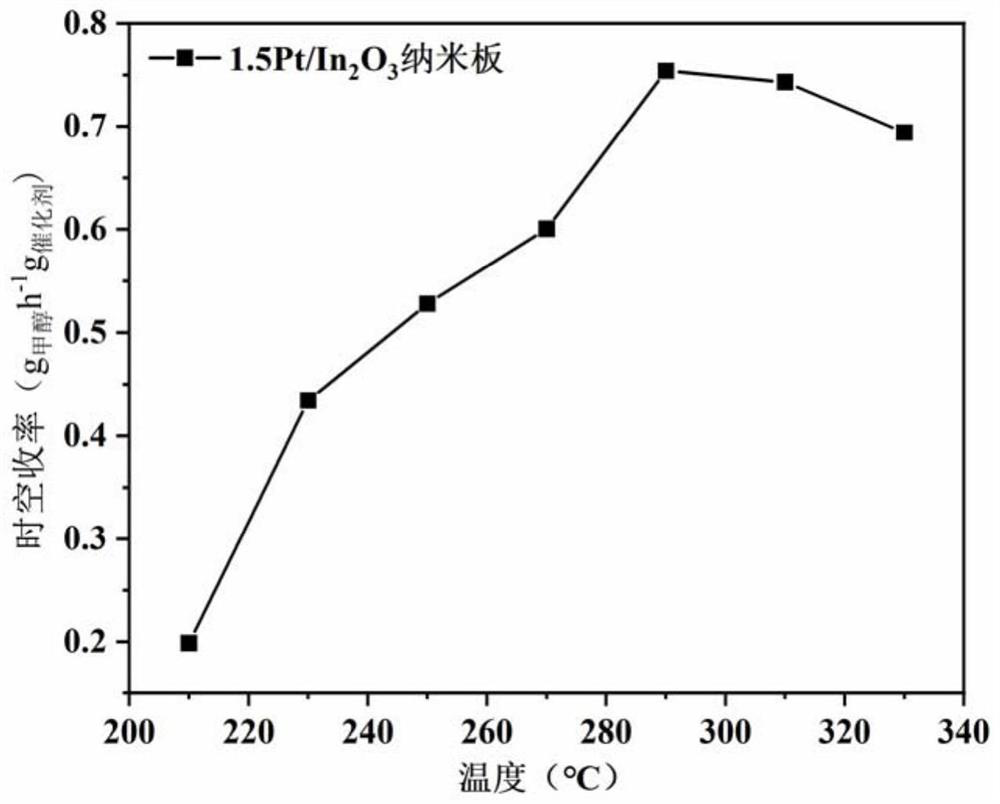

[0063] For excellent catalytic activity, the oxygen vacancies on the surface of the catalyst in traditional CO 2 Activated as a basic site, that is, CO 2 Active sites, the increase of oxygen vacancies will be beneficial for CO 2 The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com