Preparation method of dispersed graphene with bifunctional ligands for coatings

A dual-functional group, dispersed graphite technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of complex technical means and unsuitable water phase systems, and achieve simple process routes, excellent performance, and improved corrosion resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

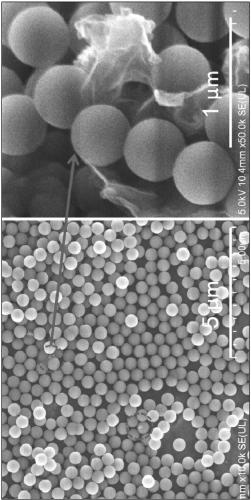

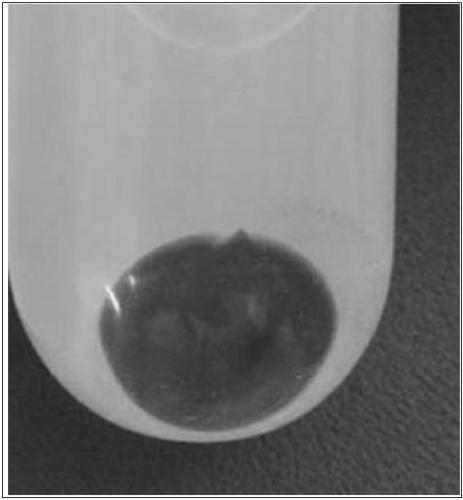

[0029] refer to Figure 8 , a kind of preparation method of bifunctional ligand dispersed graphene for coating, comprises the following steps:

[0030] (1) Get 11050 liters of pure water as a solvent, add 10 moles of silicon dioxide and 1 mole of p-aminobenzoic acid successively under the condition of magnetic stirring, stir with a magnetic stirrer for 10 minutes, add 0.05 moles of graphene during the stirring process, and obtain Mix the solution, the rotating speed of the magnetic stirrer is 800 rpm, and the temperature is 10 degrees Celsius; the graphene is graphene containing carbon-oxygen bond defects prepared by redox method;

[0031] (2) Stir the mixed solution described in step (1) for 3 hours, the rotating speed of the magnetic stirrer is 500 rpm, the temperature is 10 degrees Celsius, and the silica-graphene is obtained by drying after centrifugation, and the centrifugal speed is 5000 rpm, The centrifugation time is 10 minutes, centrifuged three times, and the silica...

Embodiment 2

[0035] A preparation method for coating bifunctional ligand-dispersed graphene, comprising the following steps:

[0036] (1) Take 65 liters of ethanol as a solvent, add 10 moles of silicon dioxide and 50 moles of lysine successively under the condition of magnetic stirring, stir with a magnetic stirrer for 20 minutes, add 5 moles of graphene during the stirring process, and obtain a mixed solution , the rotating speed of the magnetic stirrer is 600 rpm, and the temperature is 25 degrees Celsius; the graphene is graphene containing carbon-oxygen bond defects prepared by combustion method;

[0037] (2) Stir the mixed solution described in step (1) for 2 hours, the rotating speed of the magnetic stirrer is 600 rpm, and the temperature is 25 degrees Celsius, and the centrifugal operation is performed at a centrifugal speed of 8000 rpm, and the centrifugation time is 8 minutes. Three times, the obtained oxide-graphene was washed with pure water between two separate centrifugation o...

Embodiment 3

[0041] A preparation method for coating bifunctional ligand-dispersed graphene, comprising the following steps:

[0042] (1) Take 320 liters of pure water as a solvent, add 10 moles of titanium dioxide and 20 moles of p-aminobenzoic acid successively under the condition of magnetic stirring, stir with a magnetic stirrer for 5 minutes, add 2 moles of graphene during the stirring process, and obtain a mixed solution , the rotating speed of the magnetic stirrer is 800 rpm, and the temperature is 50 degrees Celsius; the graphene is graphene containing carbon-oxygen bond defects prepared by redox method;

[0043] (2) Stir the mixed solution described in step (1) for 1 hour, the rotating speed of the magnetic stirrer is 800 rpm, and the temperature is 50 degrees Celsius, and the centrifugal operation is performed at a centrifugal speed of 10000 rpm, and the centrifugation time is 10 minutes. Three times, the obtained titanium dioxide-graphene was washed with pure water between two c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com