Preparation method of poly-L-lactic acid tissue filling agent

A poly-L-lactic acid and filler technology, which is applied in the fields of beauty and medical treatment, can solve the problems of small size, inability to achieve filling effect, low accumulation concentration of lactic acid, etc., and achieve high production efficiency, easy transportation and storage, and simple and convenient process route Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

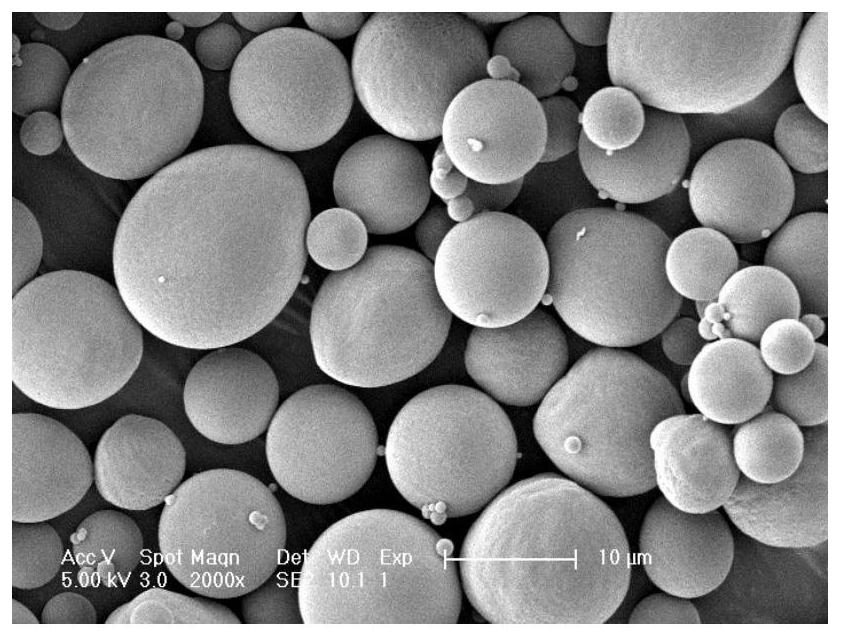

Image

Examples

Embodiment 1

[0038] A preparation of poly-L-lactic acid tissue filler, specifically comprising the following steps:

[0039] Step 1: Bulk polymerization: Put 1kg of L-lactide and 0.3g of stannous octoate into the reactor, repeat 3 times of vacuuming to -0.095MPa, and fill with protective gas, so that the reactor is a protective gas atmosphere and then evacuated Vacuum to -0.1MPa, seal; heat the reactor to 125°C and react for 8h;

[0040] Step 2: Dispersion: Add 3000ml of dichloromethane to the reactor in Step 1, and stir and dissolve for 10 hours to obtain a solution;

[0041] Step 3: Purification: Slowly add the solution in step 2 to diethyl ether dropwise under stirring at a rate of 1-3 L / min. After adding all the solution, continue stirring for 0.5 hours to obtain a solid dispersion suspension.

[0042] Step 4: Suction filtration: Suction filtration of the solid dispersion suspension obtained in Step 3 to obtain a filter cake.

[0043] Step 5: Drying: vacuum-dry the filter cake obtain...

Embodiment 2

[0051] A preparation of poly-L-lactic acid tissue filler, specifically comprising the following steps:

[0052] Step 1: Bulk polymerization: Put 1kg of L-lactide and 0.5g of creatinine into the reactor, repeat 3 times of vacuuming to -0.095MPa, and fill in the protective gas, so that the reactor is in a protective gas atmosphere and then evacuated to -0.095MPa -0.1MPa, sealed; heat the reactor to 120°C and react for 10h;

[0053] Step 2: Dispersion: Add 4000 ml of chloroform to the reactor in step 1, and stir and dissolve for 12 hours to obtain a solution;

[0054] Step 3: Purification: Slowly add the solution in Step 2 to ethanol dropwise at a rate of 1-3 L / min under stirring. After adding all the solution, continue stirring for 0.5 hours to obtain a solid dispersion suspension.

[0055] Step 4: Suction filtration: Suction filtration of the solid dispersion suspension obtained in Step 3 to obtain a filter cake.

[0056] Step 5: Drying: vacuum-dry the filter cake obtained in...

Embodiment 3

[0064] A preparation of poly-L-lactic acid tissue filler, specifically comprising the following steps:

[0065] Step 1: Bulk polymerization: put 1kg of L-lactide and 0.7g of creatinine hydrochloride into the reactor, repeat 3 times of vacuuming to -0.095MPa, and fill with protective gas to make the reactor a protective gas atmosphere Vacuumize to -0.1MPa and seal; heat the reactor to 130°C and react for 10h;

[0066] Step 2: Dispersion: Add 5000ml of chloroform to the reactor in step 1, and stir and dissolve for 24 hours to obtain a solution;

[0067] Step 3: Purification: Slowly add the solution in Step 2 to ethanol dropwise at a rate of 1-3 L / min under stirring. After adding all the solution, continue stirring for 0.5 hours to obtain a solid dispersion suspension.

[0068] Step 4: Suction filtration: Suction filtration of the solid dispersion suspension obtained in Step 3 to obtain a filter cake.

[0069] Step 5: Drying: vacuum-dry the filter cake obtained in Step 4 at 45°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com