Synthesis method for Retapamulin

A technology of retamoline and a synthesis method, applied in the field of pharmaceutical antibiotics, can solve the problems of increasing the difficulty of processing, difficult to control the purity of intermediates of retamoline in each step, unable to guarantee the quality of the final product, etc., and achieves significant economic value. , The effect of low production cost and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

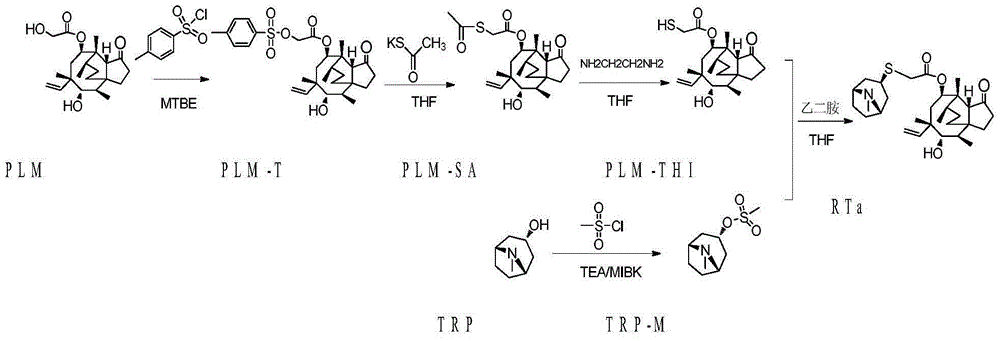

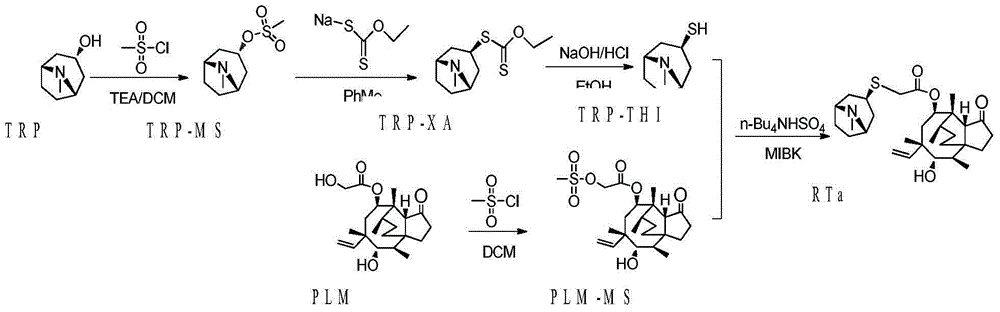

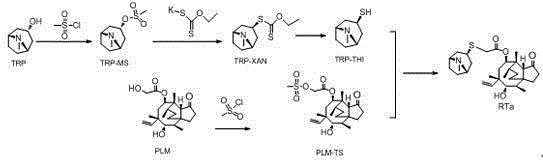

Method used

Image

Examples

example 1

[0056] Step a: Preparation of pleuromutilin mesylate (PLM-TS)

[0057] Weigh 189.25g (0.5mol) of pleuromutilin, 104.86g (0.55mol) of p-toluenesulfonyl chloride was dissolved in 946mL of dichloromethane, and 55.65g of p-triethylamine (dissolved in 55mL of dichloromethane ), after the dropwise addition, continue to react at 10°C for 2 hours, wash the reaction solution once with 500mL water, once with 250mL saturated saline, spin dry dichloromethane, recrystallize with absolute ethanol to obtain PLM-TS253.03g, Yield 95.0%.

[0058] Step b: Preparation of Tropinol Mesylate (TRP-MS)

[0059] Weigh 200.0g (1.42mol) of tropinol, 158.1g (1.56mol) of triethylamine and dissolve in 1000mL of dichloromethane solution, cool to -10~0°C, add dropwise 178.9g of methanesulfonyl chloride ( Dissolved in 200mL dichloromethane), after the dropwise addition, keep this temperature to continue the reaction for 2 hours, after TLC monitors the reaction is complete, add 300mL of 10% potassium carbonat...

example 2

[0067] Step a: Preparation of pleuromutilin mesylate (PLM-TS)

[0068] Weigh 325.0g (0.86mol) of pleuromutilin, 213.15g (1.12mol) of p-toluenesulfonyl chloride were dissolved in 1625mL of dichloromethane, and 113.13g of p-triethylamine (dissolved in 100mL of dichloromethane ), after the dropwise addition, continue to react at 40°C for 6 hours, wash the reaction solution once with 800mL water, once with 400mL saturated saline, spin dry dichloromethane, recrystallize with absolute ethanol to obtain PLM-TS445.3g, Yield 97.2%.

[0069] Step b: Preparation of Tropinol Mesylate (TRP-MS)

[0070] Weigh 400.0g (2.84mol) of tropinol, and dissolve 477.2g (3.69mol) of diisopropylethylamine in 2000mL of dichloromethane solution, cool down to -10~0°C, add methanesulfonyl chloride dropwise under nitrogen protection 422.9g (dissolved in 400mL dichloromethane), after the dropwise addition, keep the temperature and continue to react for 6 hours, after TLC monitors the reaction is complete, a...

example 3

[0078] Step a: Preparation of pleuromutilin mesylate (PLM-TS)

[0079] Weigh 378.5.0g (1.0mol) of pleuromutilin, 228.78g (1.2mol) of p-toluenesulfonyl chloride were dissolved in 1892mL of dichloromethane, and 121.43g of p-triethylamine (dissolved in 120mL of dichloromethane Middle), after the dropwise addition, continue to react at 30°C for 4 hours, wash the reaction solution with 1000mL water once, wash once with 500mL saturated saline, spin dry dichloromethane, and recrystallize with absolute ethanol to obtain PLM-TS523.6g , yield 98.3%.

[0080] Step b: Preparation of Tropinol Mesylate (TRP-MS)

[0081] Weigh 500.0g (3.54mol) of tropinol, 549.1g (4.25mol) of diisopropylethylamine and dissolve it in 2500mL of dichloromethane solution, cool down to -10~0°C, add methanesulfonyl chloride dropwise under nitrogen protection 486.8g (dissolved in 500mL dichloromethane), after the dropwise addition, keep the temperature and continue to react for 5 hours, after TLC monitors the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com