System and technology for simultaneously treating cutting waste fluids and high calcium and magnesium waste fluids

A technology for simultaneous processing and cutting fluid, applied in the field of water treatment, to achieve the effect of simple process route, avoiding ecological environment pollution, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

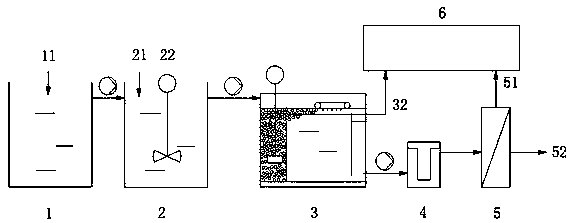

[0023] 4 cubic meters of mechanical cutting fluid with a sodium stearate concentration of 0.05 mol / L and 1 cubic meter of industrial waste liquid with a calcium and magnesium ion concentration of 0.1 mol / L, after passing through the stirring reaction tank and high calcium and magnesium waste liquid, the mixer frequency is 30Hz, stirring time 0.5 hours, enter the air flotation machine, the aerator in the air flotation machine operates to separate the suspended solids from the solution, and obtain 5.8KG suspended solids, and the solution enters the sand filter and the security filter with a filtration accuracy of 5 μm for filtration Large particles, and then under the pressure of the high-pressure plunger pump, a large number of ions in the water are separated from the water through a two-stage DTRO reverse osmosis membrane separation system (including a 75bar membrane column and a 120 / 160bar membrane column), and the recovery rate reaches 85%. The separated 4.25 tons of high-qua...

Embodiment 2

[0025] 4 cubic meters of soap liquid with a sodium stearate concentration of 0.05mol / L and 1 cubic meter of industrial waste liquid with a calcium and magnesium ion concentration of 0.1mol / L, after passing through the stirring reaction tank and high calcium and magnesium waste liquid, the frequency of the mixer is 30Hz , the stirring time is 0.5 hours, enter the air flotation machine, the aerator in the air flotation machine runs to separate the suspended solids from the solution, and obtain 6.1KG suspended solids, and the solution enters the sand filter and the security filter with a filtration accuracy of 5 μm for filtration. Particulate matter, and then under the pressure of the high-pressure plunger pump, a large number of ions in the water are separated from the water through a two-stage DTRO reverse osmosis membrane separation system (including a 75bar membrane column and a 120 / 160bar membrane column), and the recovery rate reaches 89%. The 4.45 tons of high-quality water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com