Method for continuously preparing graphene material in cut mode through screw machine

A screw machine and graphene technology, applied in the field of graphene materials, can solve problems such as unsustainable and stable large-scale production, small two-dimensional size area, graphite lattice damage, etc., achieve significant market application value, small investment, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) Graphite powder with a mass fraction of 85%, etherified starch with a mass fraction of 8%, polyvinyl alcohol with a mass fraction of 4%, glycerin with a mass fraction of 2.5%, and dodecane with a mass fraction of 0.5% Sodium sulfate was mixed and dispersed for 10 minutes at a speed of 800 rpm in a high-speed mixer to obtain a premix;

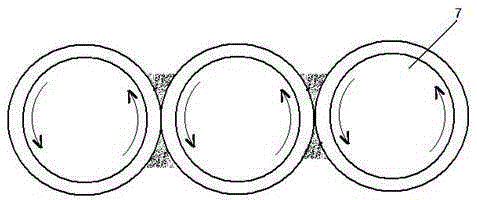

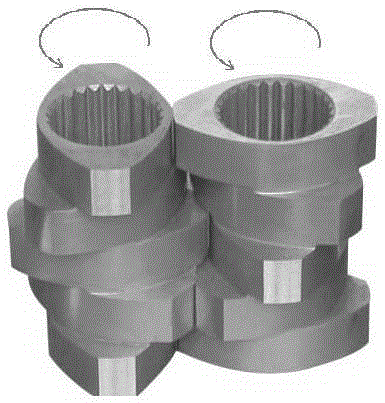

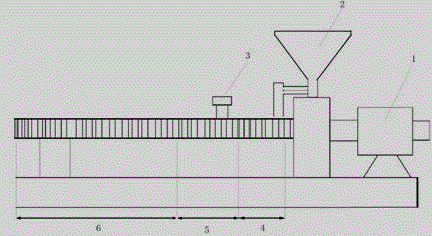

[0049] (2) Put the premix obtained in step (1) into the main feeding port of the inline co-rotating three-screw machine, and the screw machine is sequentially provided with a dispersion orientation section, a shear carbonization section, a shear In the cutting and peeling section, the temperature of the mixing section is set at 100-200°C, the temperature of the shearing carbon section is set at 300-500°C, and the temperature of the shearing and peeling section is set at 100-300°C. When the screw rotates at a speed of 500rpm, the The section consists of two sets of 56 / 56 conveying thread elements, two sets of toothed discs, four sets o...

Embodiment 2

[0053] (1) Flake graphite with a mass fraction of 40%, highly oriented graphite with a mass fraction of 40%, esterified starch with a mass fraction of 10%, polyvinyl alcohol with a mass fraction of 7.5%, and ethyl alcohol with a mass fraction of 1.5% Glycol, the sodium dodecylbenzene sulfonate that mass fraction is 1% mixes and disperses 15min with the rotating speed of 1000rpm in high-speed mixer, obtains premixture;

[0054] (2) Add the premix obtained in step (1) into the main feeding port of the product-shaped co-rotating three-screw machine, and the screw machine is sequentially provided with a dispersion orientation section, a shear carbonization section, and a shearing section from the feed end to the discharge end. For the cutting and peeling section, the screw machine has an aspect ratio greater than 30 / 1 and a screw diameter of 65mm. The temperature of the mixing section is set at 100-200°C, the temperature of the shearing carbon section is 300-500°C, and the setting ...

Embodiment 3

[0059] (1) The mass fraction is 90% expanded graphite, the mass fraction is 3% pregelatinized starch, the mass fraction is 2% etherified starch, the mass fraction is 3% polyvinyl alcohol, and the mass fraction is 1.5% Pentaerythritol and polyvinylpyrrolidone with a mass fraction of 0.5% were mixed and dispersed for 25 minutes at a speed of 1200 rpm in a high-speed mixer to obtain a premix;

[0060] (2) Put the premix obtained in step (1) into the main feeding port of the co-rotating twin-screw machine, and the screw machine is sequentially equipped with a dispersed orientation section, a shear carbonization section, and a shear peeling section from the feed end to the discharge end , the setting temperature of the mixing section is 100-200°C, the setting temperature of the shearing carbon section is 300-500°C, the setting temperature of the shearing stripping section is 100-300°C, when the screw rotates at a speed of 1000rpm, the dispersion orientation section consists of two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com