Composition for transparent adhesive/pressure-sensitive adhesive sheet, process for producing same, and transparent adhesive/pressure-sensitive adhesive sheet

A technology of adhesive sheet and composition, which is applied in the field of transparent adhesive adhesive sheet and composition for transparent adhesive adhesive sheet, which can solve the problems of water-absorbing acid corrosion, inaccessibility, safety and unpreferability, etc., and achieve adhesion The effect of good force and high shear stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

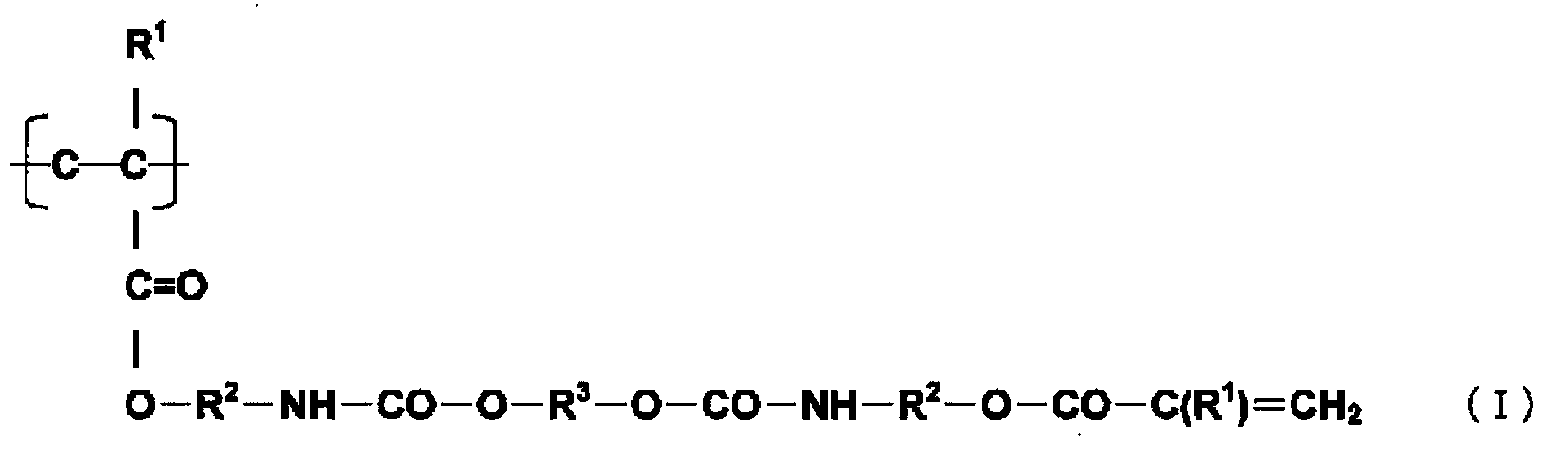

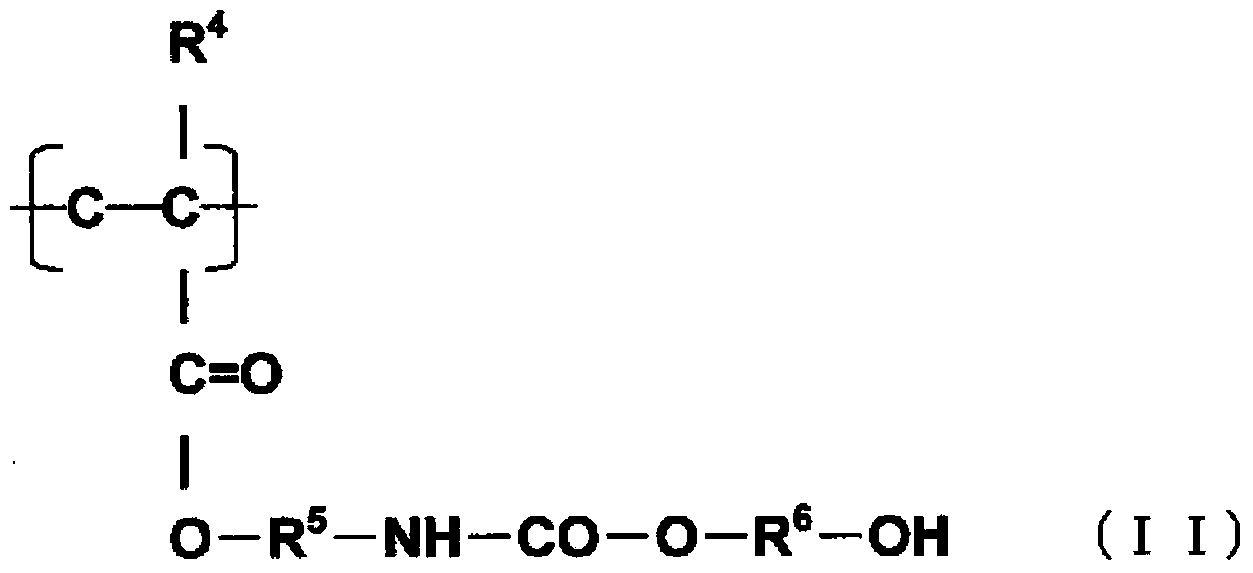

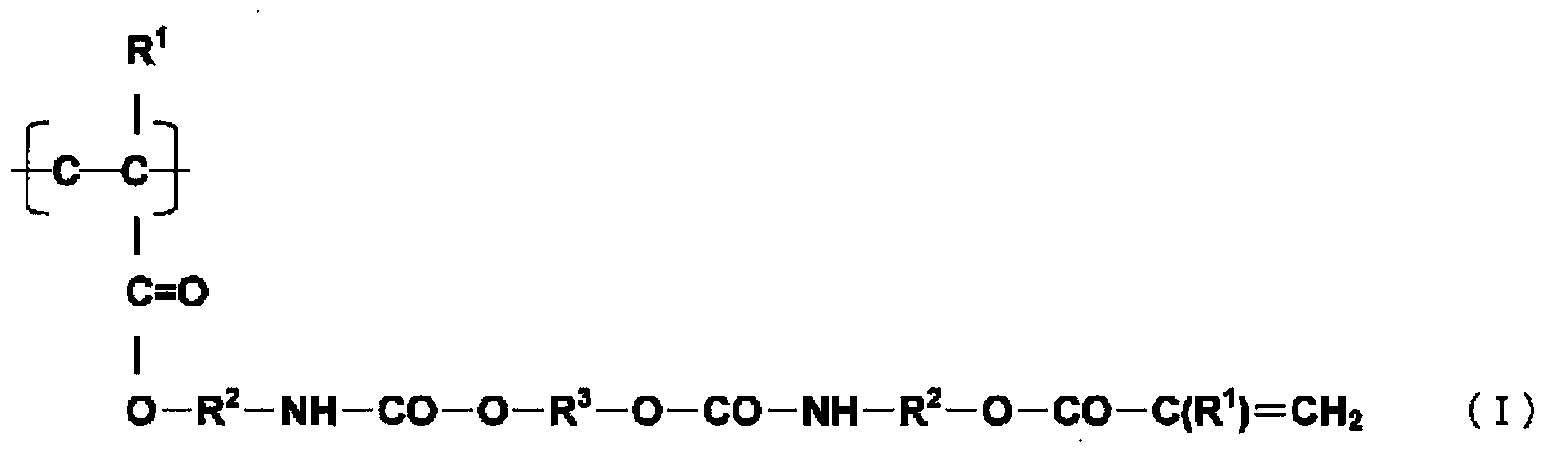

Method used

Image

Examples

Embodiment 1~4、 comparative example 1~2

[0112] A crosslinking agent and a photopolymerization initiator were mixed with the compositions shown in Table 2, and the solid content concentration was adjusted with n-propyl acetate to obtain an adhesive composition solution (solid content concentration: 50% by mass). The obtained adhesive composition solution was mixed using a disperser to prepare a composition solution for a transparent adhesive sheet. This solution was cast-coated on one side of a polyethylene terephthalate (PET) film with a thickness of 50 μm so that the thickness after drying was 50 μm (coating layer thickness: 100 μm), and heated at 50° C. After drying for 5 minutes and heating and drying at 110° C. for 3 minutes, the release-treated side of the release film of a 50-μm-thick PET film on one side was covered with the adhesive side. Then, aging was performed at 40° C. for 72 hours to prepare a transparent pressure-sensitive adhesive sheet (PET base type).

[0113] (Acid Value of Composition for Transp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com