High-shear device and method of high shearing

A high-shear and screw technology, applied in the field of high-shear devices, can solve the problems of high-shear efficiency reduction, inability to apply constant shear stress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

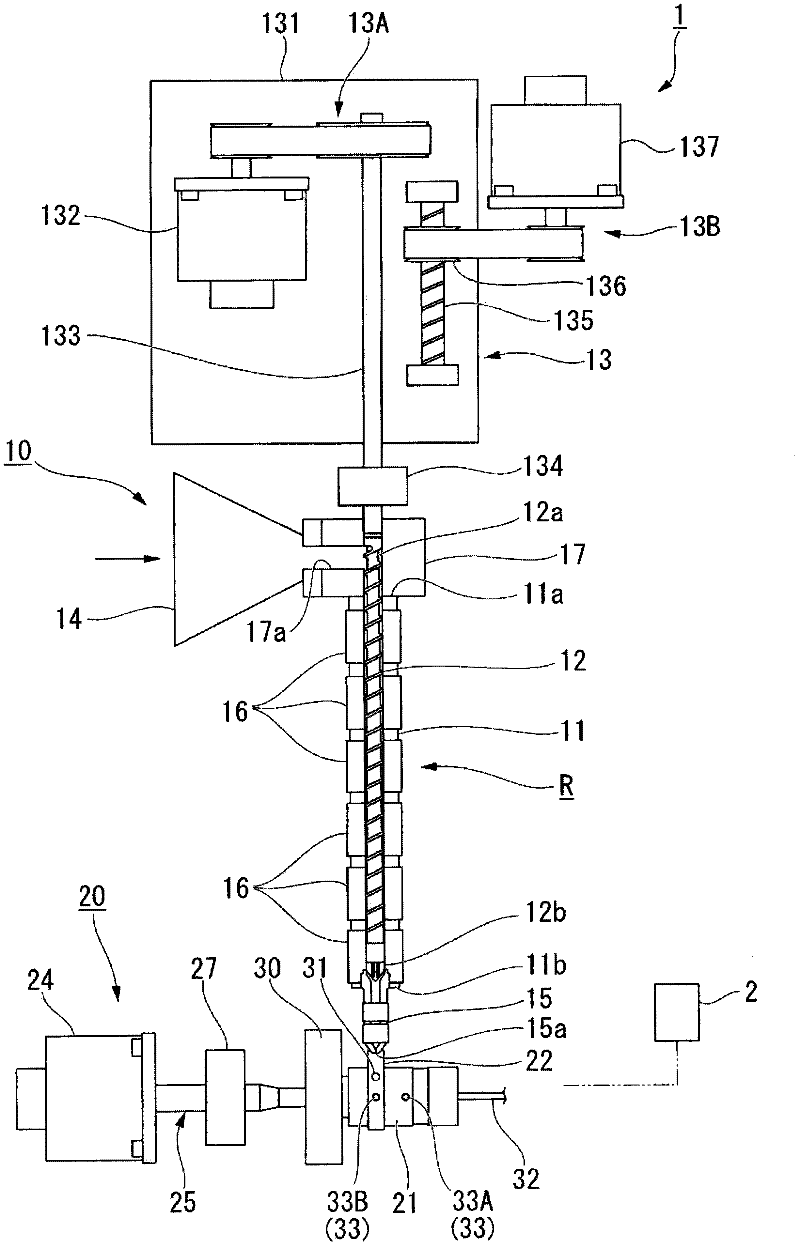

[0106] In the example, using figure 1 In the high-shear device 1 shown, the polymer hybrid resin obtained by mixing polycarbonate (PC) and acrylic acid (PMMA) at a ratio of 8:2 is nano-dispersed using a high-shear unit to produce a polymer hybrid resin. Extrusion.

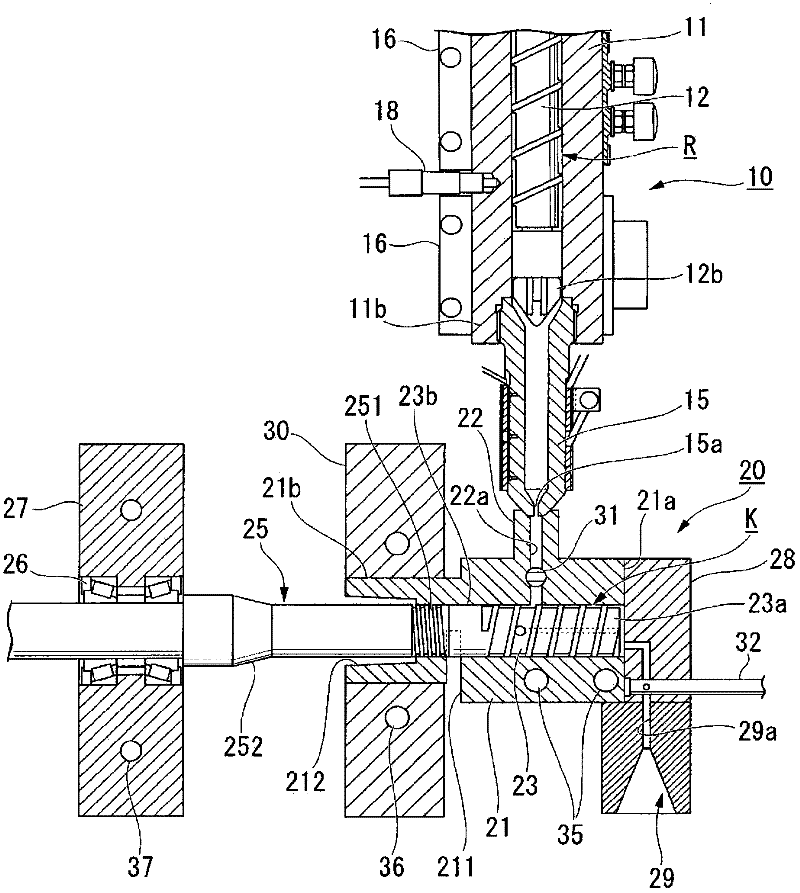

[0107] First, in the plasticizing unit, the temperature of the heating cylinder 11 is set at 220° C., and the plasticizing screw 12 is rotated at a low speed of 300 rpm or less to plasticize and melt the above-mentioned resin to produce uniformly kneaded molten resin.

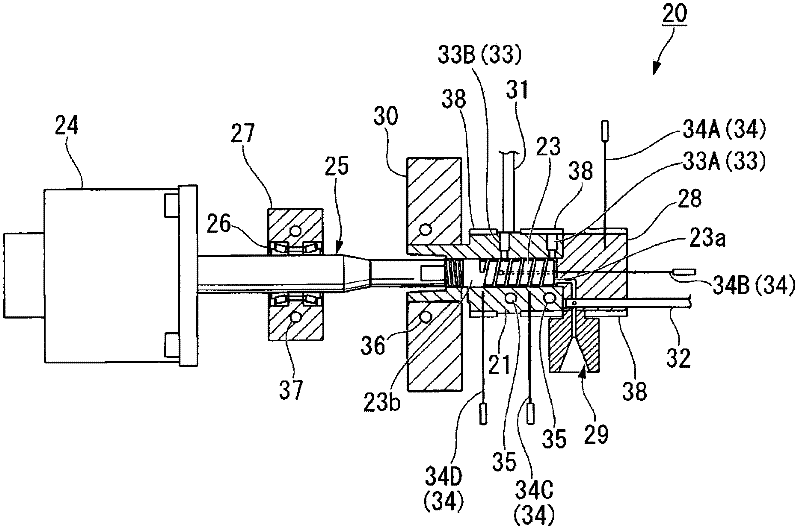

[0108] Inject the molten resin into the heating cylinder 21 of the high-shear unit 20, using a screw diameter of 28 mm, a pitch of 11 mm, a width of the screw thread (screw crest) of 2 mm, a diameter of the return hole of 2.5 mm, and an effective length of the screw (from the front end of the screw to the return) The distance from the center of the discharge port of the hole) to the internal return type screw 23 of 50 mm, the screw speed is 2500 rpm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com