Apparatus for controlling laneway bottom heave

A technology of roadway and bottom sill, which is applied in the installation of bolts, mining equipment, earthwork drilling and mining, etc. It can solve the problems of bottom beam failure and heavy workload, and achieve the effect of simple bottom beam, reduced bottom sill, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

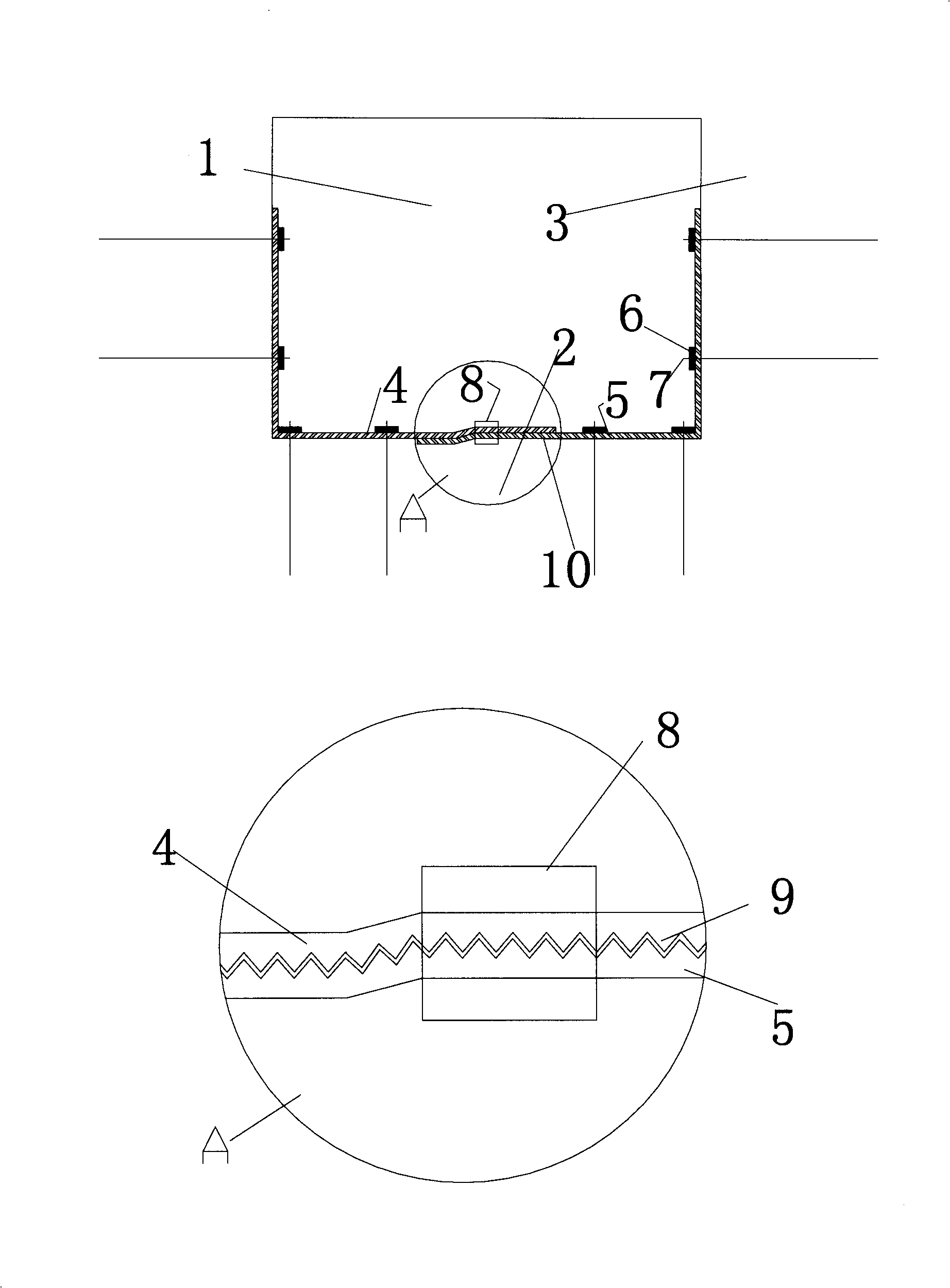

[0013] As shown in the accompanying drawings, the present invention includes a roadway 1 base plate 2 and two gangs 3 anchor rods 7, anchor rod 7 pallets 6, steel belts 4, 5 with teeth 9 and round holes and long strip holes, and a constant force clamping device 8 , The steel strips 4, 5 and the constant force clamping device together constitute the bottom beam 10. When the bottom plate 2 of the roadway 1 bulges under various factors, the bottom plate 2 provides an upward force on the bottom beam 10. Under the fixing action of the side 3 of the roadway 1 and the anchor rod 7 at the bottom corner, the steel belt 4 with teeth 9 and holes , 5 by tension. Under the action of the constant force clamping device 8, a certain friction force is generated between the steel strips 4 and 5. When the tensile force on the steel strips 4 and 5 is greater than the friction force between the steel strips 4 and 5, the steel strip 4 and the steel strip 5 The tooth slots at the overlapping place ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com