Three-bench four-step staggered construction method for large section soft formation tunnel

A technology of weak ground and construction methods, applied in tunnels, tunnel linings, underground chambers, etc., can solve problems such as short steps, unfavorable mechanized operations, temporary support reduces construction efficiency, large settlement and convergence deformation, etc., to achieve reduction The sinking and convergence of the vault, shortening the time of closing and forming a loop, and reducing the effect of exposure time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

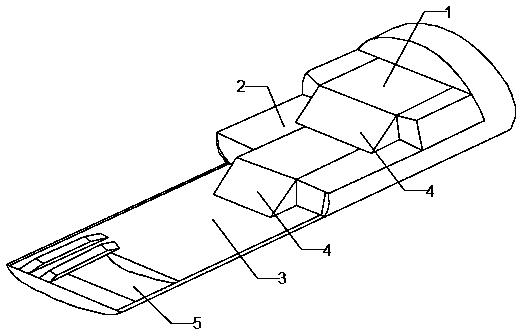

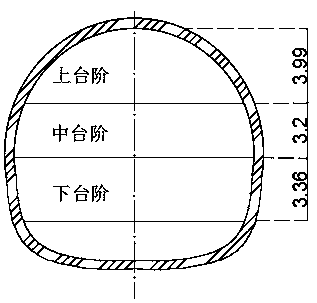

[0042] A three-step and four-step staggered construction method for large-section soft ground tunnels, such as figure 1 As shown, it includes an upper step 1, a middle step 2, and a lower step 3 arranged in sequence, and the right side of the upper step 1, the middle step 2, and the left side of the lower step 3 constitute the first working plane; the upper step 1, The left side of the middle step 2 and the right side of the lower step 3 form the second working plane; the same side of the middle part of the upper step 1 and the middle step 2 is respectively provided with core soil 4; mainly includes the following steps:

[0043] Step 1: The first working plane and the second working plane are alternately constructed, and progressive construction is adopted; each pair of the first working plane and the second working plane is constructed once as a cycle; the first working plane and the second working plane Synchronous construction is adopted respectively in

[0044] Step 2: Ca...

Embodiment 2

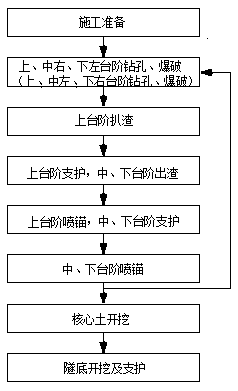

[0049] This embodiment is further optimized on the basis of Embodiment 1. The construction of the first working plane and the second working plane in the step 1 includes the following steps respectively:

[0050] Step 01: Carry out drilling and blasting operations on the corresponding construction surfaces of upper step 1, middle step 2, and lower step 3;

[0051] Step 02: Then, remove slag from the construction surface of the upper step 1;

[0052] Step 03: Support the upper step 1, and remove slag from the corresponding construction surfaces of the middle step 2 and lower step 3;

[0053] Step 04: Finally, spray anchors to the upper step 1, support and spray anchors to the corresponding construction surfaces of the middle step 2 and lower step 3 respectively.

[0054] In step 1 of the present invention, the first working plane and the second working plane are alternately constructed on the construction surface through the method of steps 01-04, which shortens the cycle time...

Embodiment 3

[0057] This embodiment is further optimized on the basis of embodiment 2, as figure 2 As shown, the excavator is used to process the residues of the blasting section. Firstly, the residues of the upper step 1 are removed to the corresponding construction surfaces of the middle step 2 and the lower step 3, so that the corresponding construction of the upper step 1, middle step 2, and lower step 3 The surfaces are gently sloped. The steel frame is transported to the upper step 1, and the erection operation is carried out on the upper step 1. While the upper step 1 is erected, the excavator is used to sequentially excavate the slag at the gentle slopes of the middle step 2 and the lower step 3. After the erection of the upper step 1 is completed, the air duct and water pipe are connected, and the construction of the system anchor rod, the locking foot anchor rod, and the small conduit in advance is carried out, and the erection operation is carried out on the middle step 2; The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com