Window scraper for an optical instrument

An instrument and optical surface technology, applied in the field of window scrapers for optical instruments, which can solve the problems of inability to remove particles and degraded optical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Although the exemplary embodiments have been shown and described, it will be appreciated that various changes can be made therein without departing from the spirit and scope of the invention.

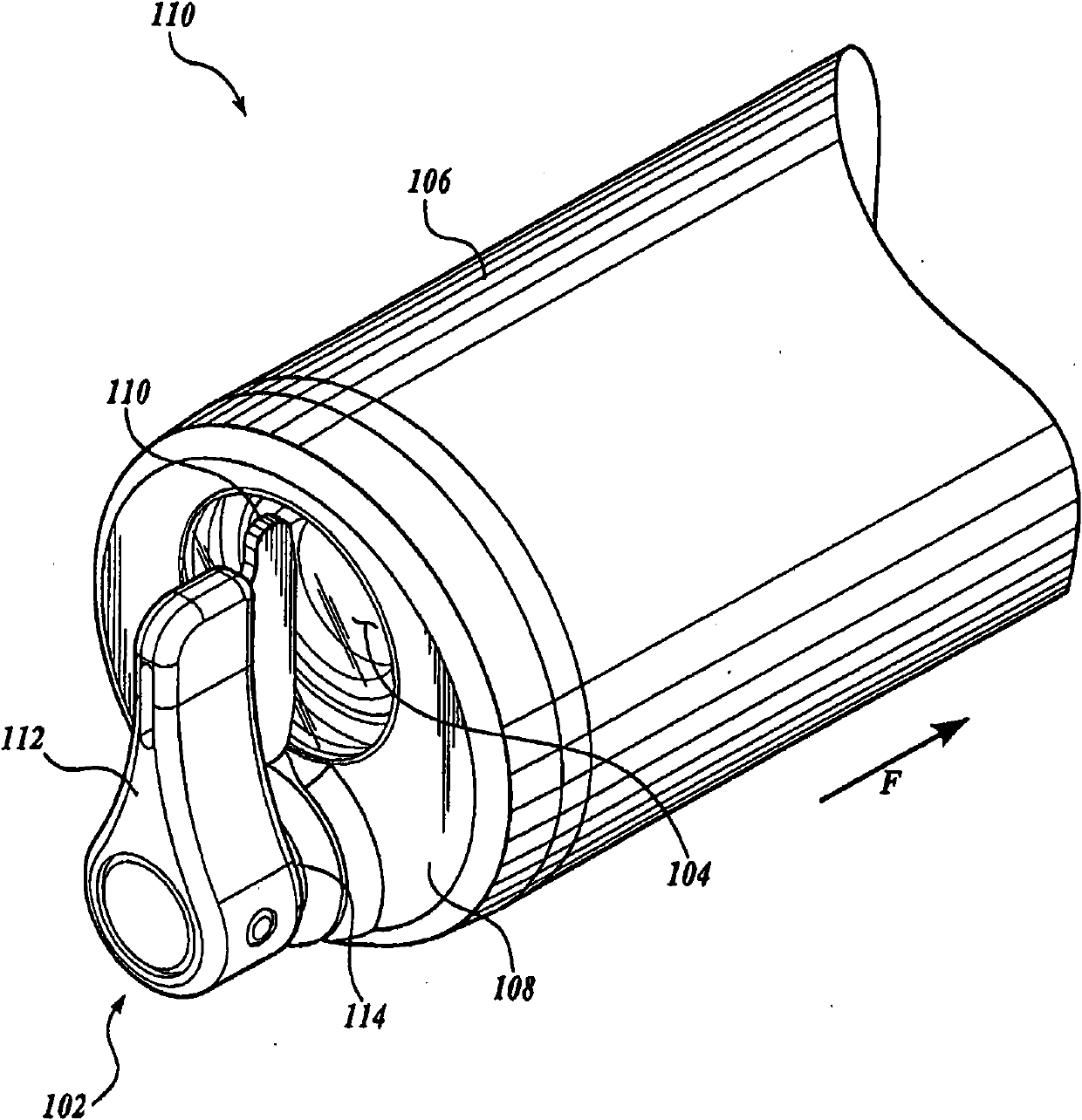

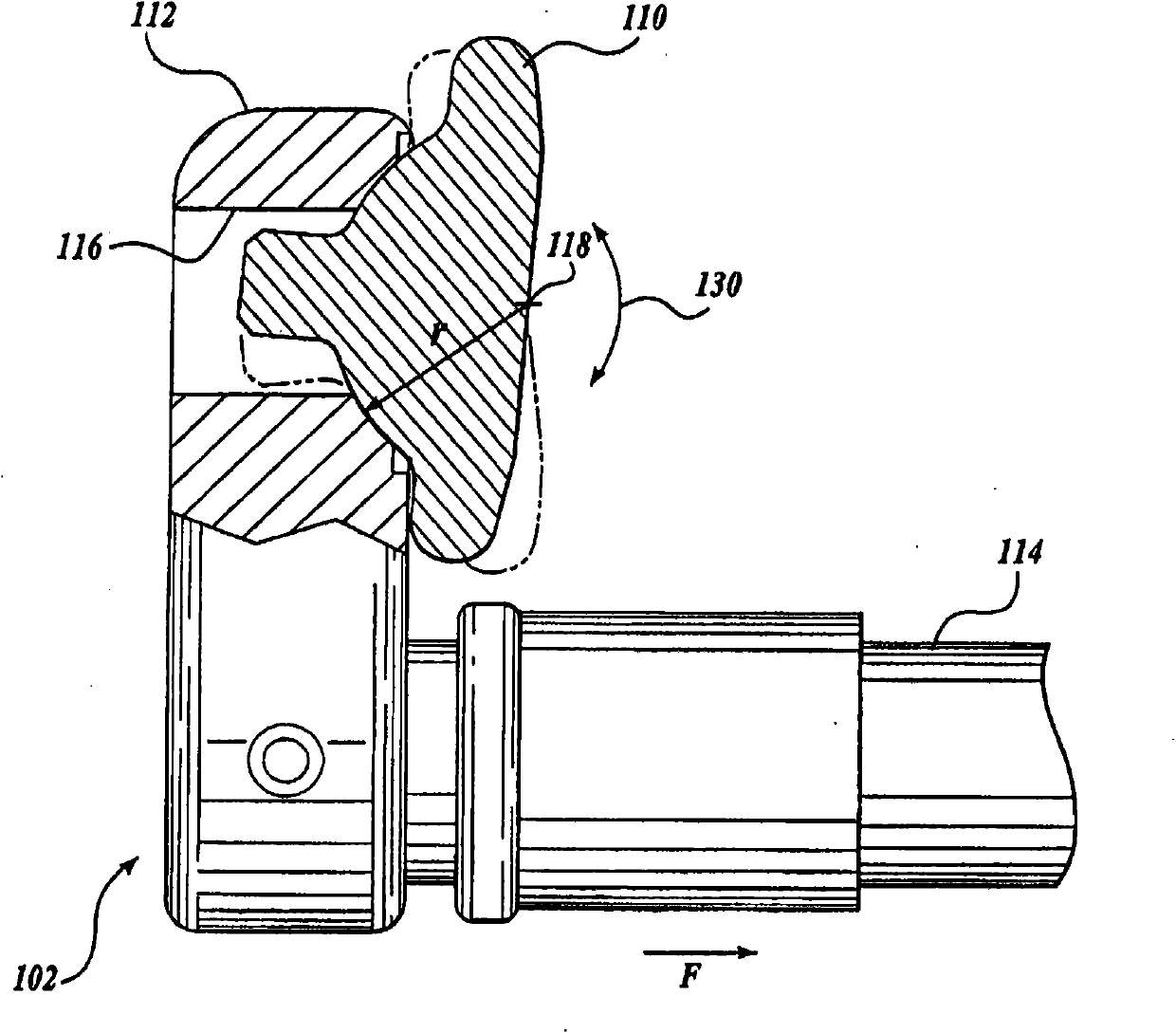

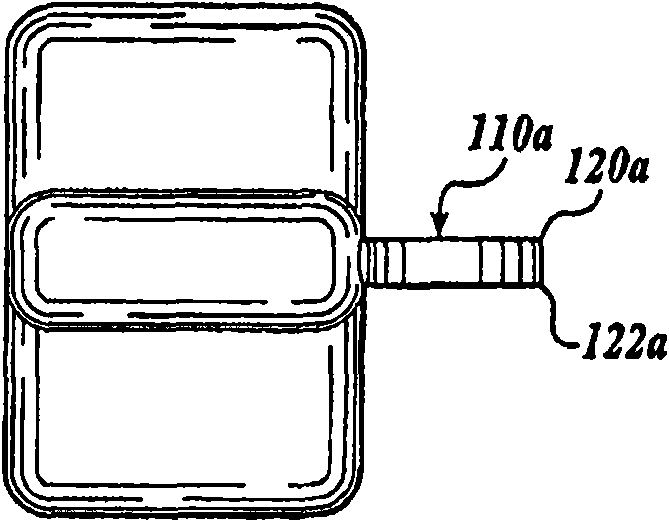

[0028] Embodiments of the present invention relate to scrapers for windows (including but not limited to the processing side optical surface of the windows). When used here, the optical surface is present in the optical instrument but is not necessarily limited to the optical instrument.

[0029] The window can be any surface that collects and attracts particles or any other type of material or a surface on which particles or any other type of material accumulate. For example, applications in which embodiments of the window scraper disclosed herein can be used include particle treatment, such as in the pharmaceutical field, where binders (such as cellulose and lactose) may accumulate on the instrument. However, other applications of the disclosed window scraper are also feasible, suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com