Method for medium sized or thin plate blank continuous casting and continuous rolling for producing superfine crystal grain steel plate and the steel plate

A technology of medium-thin slab continuous casting and ultra-fine grain, which is applied in the field of steel rolling, can solve the problems that ultra-fine grain steel is difficult to realize, and achieve the effects of shortening production time, easy smelting, and reasonable yield ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

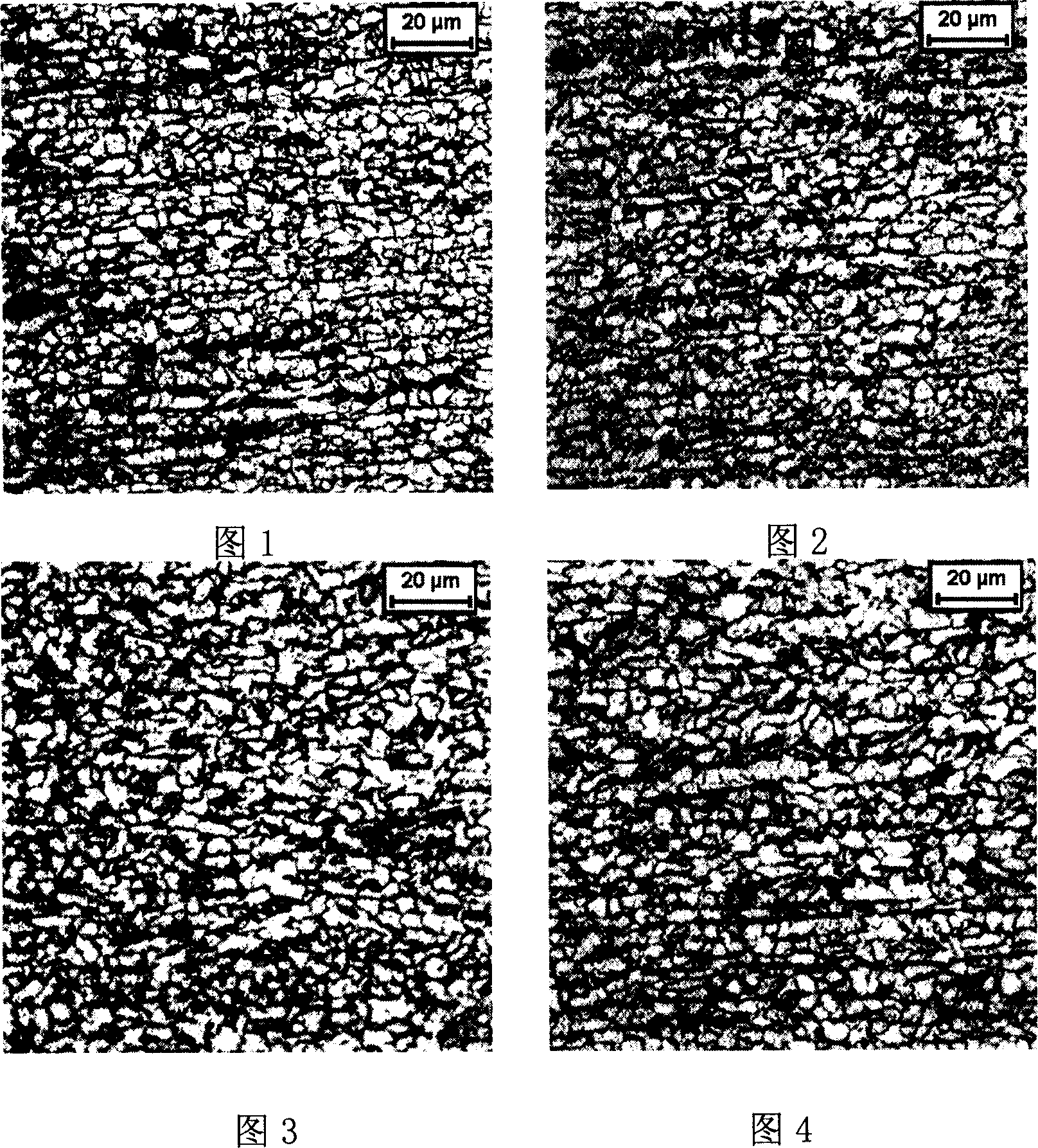

[0030] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0031] The present invention adopts the following chemical composition (weight percentage): C: 0.12~0.18%, Si: 0.15~0.35%, Mn: 0.65~1.20%, P: ≤0.02%, S: ≤0.015%, the balance is Fe and non- Impurities to avoid.

[0032] Using 4 groups of ultra-fine grain steel chemical composition set in the above range, respectively smelting on the converter, and pouring into a casting billet with a specification of 100~200mm×1000~2000mm, directly hot charging, the hot charging furnace temperature is 800℃ Above, the heating temperature is controlled between 1100 and 1280 ℃; after the billet is heated out of the furnace, it is descaled with a double-row high-pressure water descaling device; rough rolling is carried out on a two-high or four-high reversible roughing mill to thin the slab To 30~60mm; the entry temperature of the finish rolling is controlled between...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com