Magnesium-lithium alloy with enhanced long-period structure phase and preparation method thereof

A long-period structure, magnesium-lithium alloy technology, applied in the field of magnesium-lithium alloys, can solve the problems of deterioration of mechanical properties, no breakthrough progress, unstable alloy properties, etc., to achieve low density, good heat resistance, high The effect of the modulus of elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

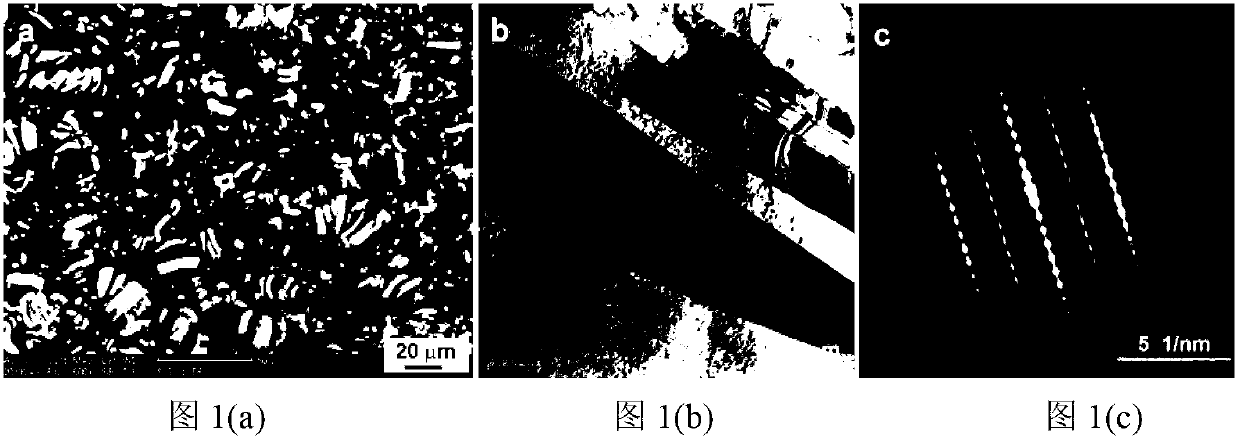

Image

Examples

Embodiment 1

[0026] The chemical composition (mass percentage) of the alloy is: 7.6% Li, 5.7% Y, 2.0 Zn, the balance is Mg, and its purity is above 99.95.

[0027] The casting, heat treatment and processing processes for preparing alloys are:

[0028]First, according to the designed alloy composition, prepare Mg, Li, Zn, Mg-20%Y master alloy in proportion. In order to ensure the quality of the ingot and reduce the introduction of impurities as much as possible, the surface of the furnace charge is polished to remove the surface oxide scale before loading the furnace. Among them, due to the high chemical activity of Li element, it must be sealed and stored or placed in kerosene, and it must be prepared immediately after use. The Li used in this example is stored in kerosene. After the Li block is cut, the surface of the lithium block is wiped clean with filter paper, and put into the furnace in the shortest time, and then the furnace cover is put on to vacuum the furnace. Put the processe...

Embodiment 2

[0035] The chemical composition (mass percentage) of the alloy is: 7.9% Li, 8.0% Y, 3.1% Zn, the balance is Mg, and its purity is above 99.95.

[0036] The melting and casting conditions and process refer to Example 1, the difference lies in: the contents of Li, Y, and Zn are different.

[0037] The heat treatment conditions and process refer to Example 1, the difference is that: the heat treatment temperature is 500° C., and the time is 7 hours.

[0038] Extrusion processing conditions and technology refer to embodiment 1. Finally, a deformed Mg-Li alloy material reinforced by LPSO structure is obtained.

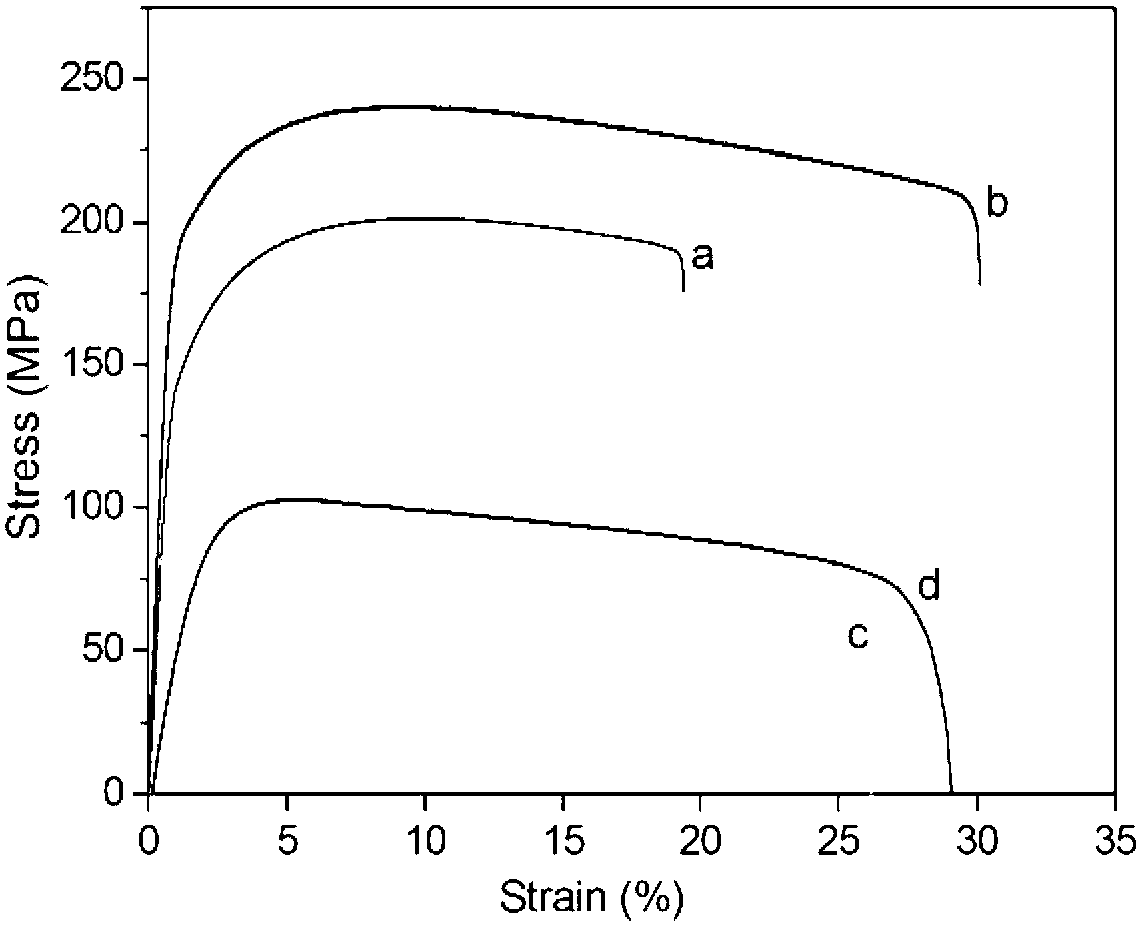

[0039] The high-performance magnesium-lithium alloy of present embodiment gained, its mechanical property is:

[0040] Room temperature: tensile strength: 264MPa, yield strength: 199MPa, elongation 35%.

[0041] 150°C: Tensile strength: 117MPa, yield strength: 96MPa, elongation 38%.

Embodiment 3

[0043] The chemical composition (mass percentage) of the alloy is: 7.8% Li, 9.6% Y, 3.8% Zn, the balance is Mg, and its purity is above 99.95.

[0044] The melting and casting conditions and process refer to Example 1, the difference lies in: the contents of Li, Y, and Zn are different.

[0045] The heat treatment conditions and process refer to Example 1, except that the heat treatment temperature is 500° C. and the time is 9 hours.

[0046] Extrusion processing conditions and technology refer to embodiment 1. Finally, a deformed Mg-Li alloy material reinforced by LPSO structure is obtained.

[0047] The high-performance magnesium-lithium alloy of present embodiment gained, its mechanical property is:

[0048] Room temperature: tensile strength: 281MPa, yield strength: 206MPa, elongation: 37%.

[0049] 150°C: tensile strength: 128MPa, yield strength: 111MPa, elongation: 46%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com