Manufacture method of dielectric substrate and metamaterial

A dielectric substrate and base material technology, applied in the field of metamaterials, can solve the problems of substrate materials that cannot be satisfied at the same time, low dielectric constant, etc., and achieve the effect of good mechanical properties, low dielectric constant, and flexible selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

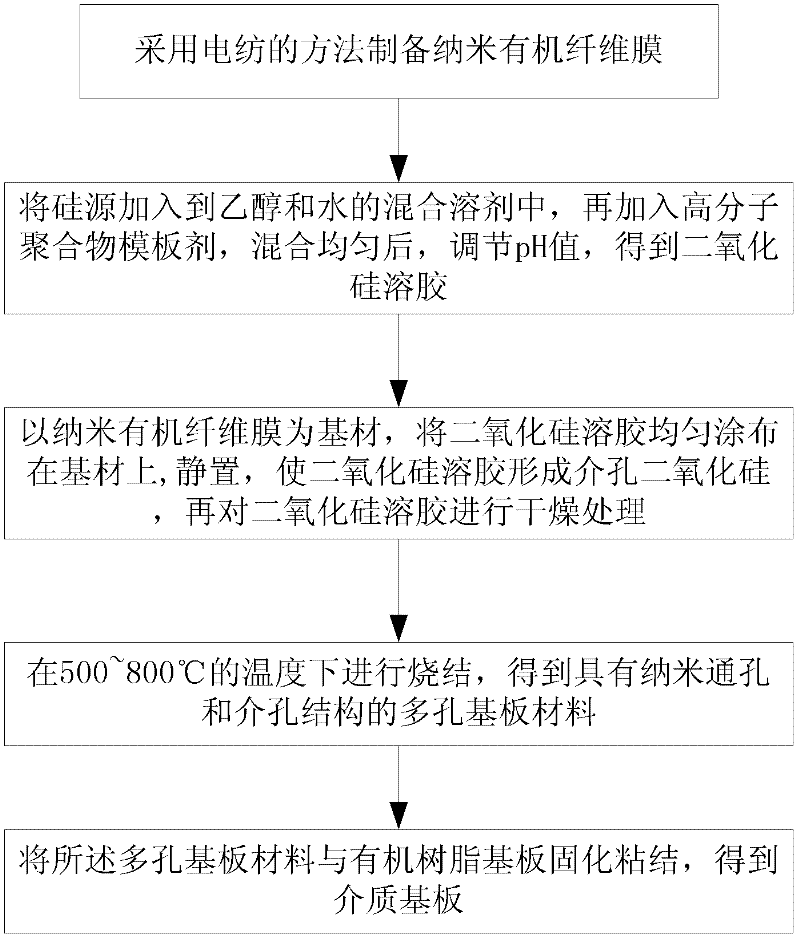

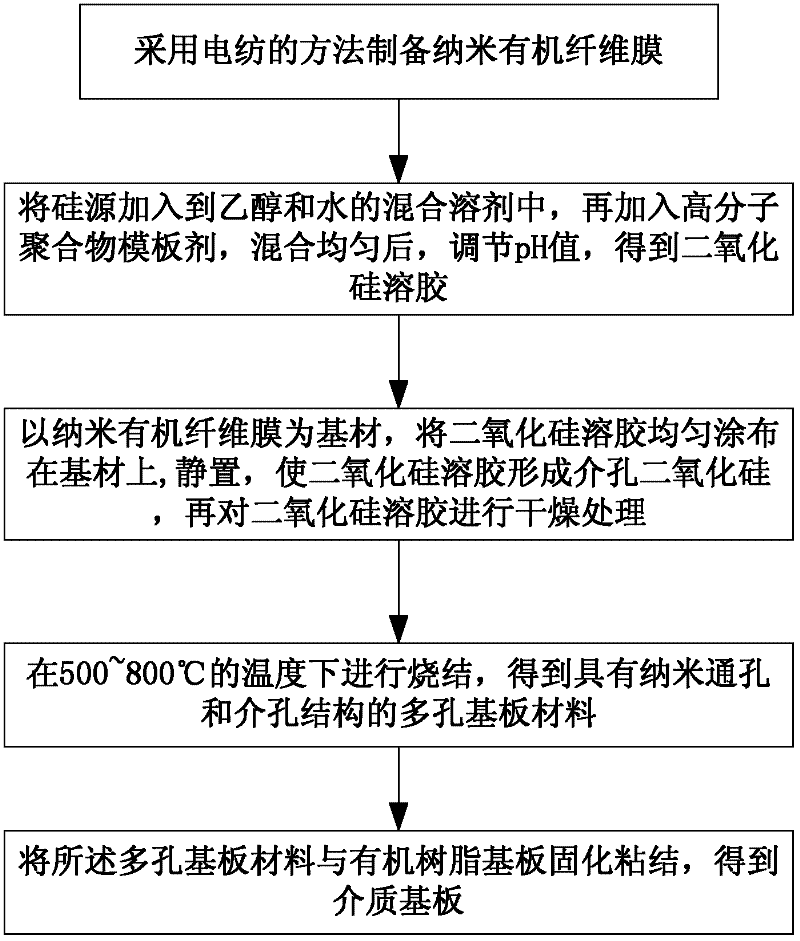

[0027] A method for preparing a dielectric substrate, the flow chart of its main preparation steps can be found in the attached figure 1 , including the following steps:

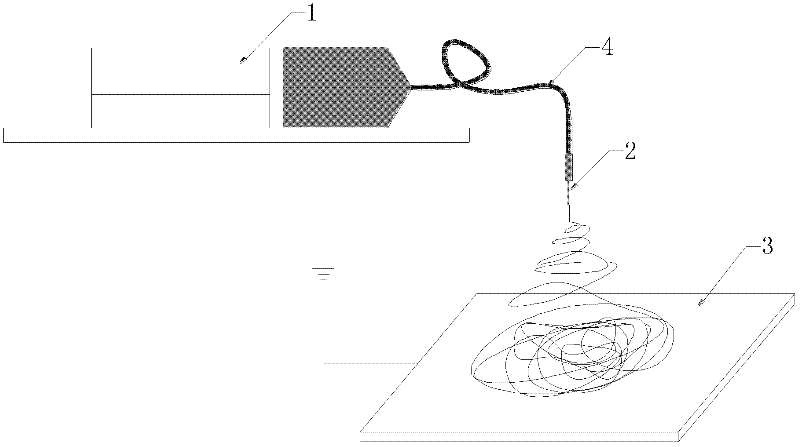

[0028] a. The method of electrospinning is used to prepare nano-organic fiber membrane. The schematic diagram of electrospinning process can be found in the attached figure 1 , the electrospinning process includes setting a syringe 1, a metal needle 2, a metal plate 3 and a pipeline 4. The specific process is: placing the organic polymer material in a molten state in the syringe 1, and the syringe 1 communicates with the metal needle 2 through the pipeline 4 , a high-voltage electric field is formed between the metal needle 2 and the metal plate 3, and the organic polymer material in the molten state can overflow from the metal needle 2 by pushing the syringe 1. Under the action of the high-voltage electric field, the organic polymer material overflowed from the metal needle 2 The material is stretched into...

Embodiment 2

[0036] A method for preparing a dielectric substrate, comprising the following steps:

[0037] a. The method of electrospinning is used to prepare nano-organic fiber membrane. The schematic diagram of electrospinning process can be found in the attached figure 1 , the electrospinning process includes setting a syringe 1, a metal needle 2, a metal plate 3 and a pipeline 4. The specific process is: placing the organic polymer solution in the syringe 1, and the syringe 1 communicates with the metal needle 2 through the pipeline 4, A high-voltage electric field is formed between the metal needle 2 and the metal plate 3. By pushing the syringe 1, the organic polymer solution can overflow from the metal needle 2. Under the action of the high-voltage electric field, the organic polymer solution overflowed from the metal needle 2 The solution is stretched into very thin nano-scale fibers, and a layer of film-like fiber material is formed on the metal plate. As a specific implementatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com