Ultrahigh-strength martensitic stainless steel and preparation method thereof

A martensitic stainless steel and ultra-high-strength technology, applied in the field of stainless steel, can solve the problems of not being widely used, the high price of stainless steel, and the increase of smelting processes, etc., and achieve the effects of reduced damage, excellent welding performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The chemical composition by weight percentage is, C: 0.11%, Cr: 11%, Mn: 0.6%, Si: 1.2%, Ni: 0.1%, Cu: 0.1%, P≤0.02%, S:≤0.02%, Yu Feedstock in the form of iron is smelted in a vacuum induction furnace. After the smelted casting is kept at 1100°C for 2 hours, forging begins, and the final forging temperature is 880°C. Then the obtained forging is heated to 980°C for 4 hours and then quickly taken out of the furnace for water quenching, followed by tempering at 220°C for 4 hours.

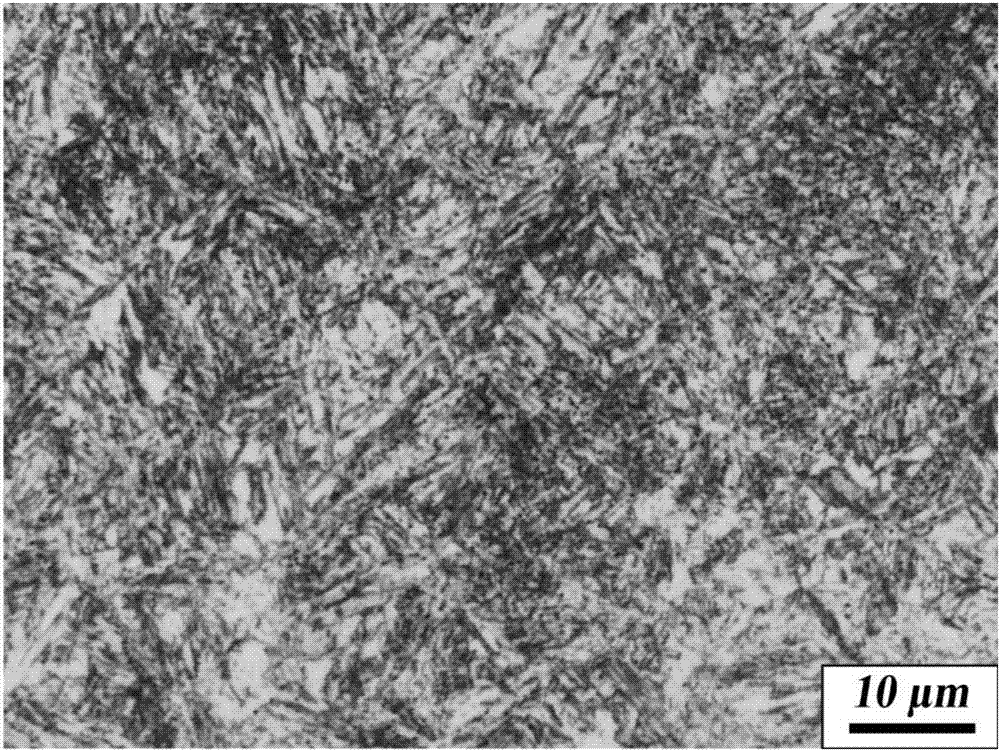

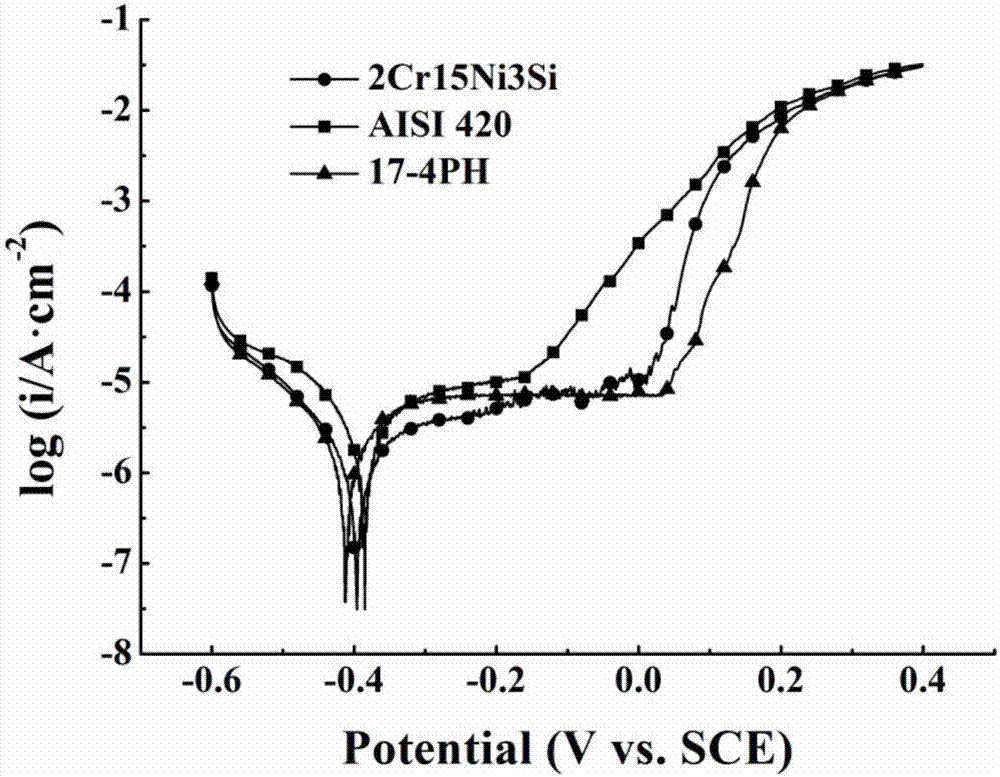

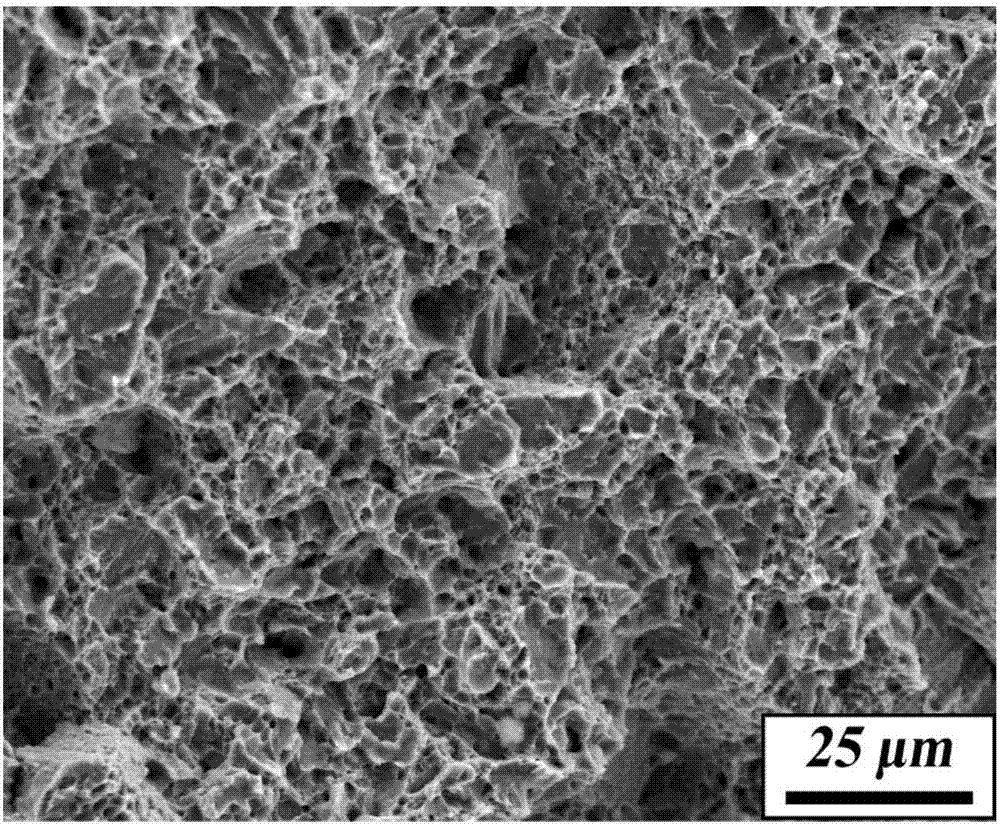

[0033] The main metallographic structure of the obtained material is lath martensite structure and nano-carbide precipitation, has excellent strength, plasticity and toughness, and has good corrosion resistance and weldability. The yield strength is 1310MPa, the tensile strength is 1610MPa, the elongation is 16%, and the impact toughness at room temperature is 61J / cm 2 .

Embodiment 2

[0035] The chemical composition by weight percentage is, C: 0.24%, Cr: 12%, Mn: 2.0%, Si: 2.5%, Ni: 3.8%, Cu: 0.3%, P≤0.02%, S:≤0.02%, The raw material with the balance being iron is smelted in a vacuum induction furnace. After the smelted casting is kept at 1150°C for 2 hours, forging begins, and the final forging temperature is 890°C. Then the obtained forgings are heated to 1000°C for 4 hours and then quickly taken out of the furnace for water quenching, followed by tempering at 250°C for 4 hours.

[0036] The main metallographic structure of the obtained material is lath martensite structure and nano-carbide precipitation, has excellent strength, plasticity and toughness, and has good corrosion resistance and weldability. The yield strength is 1320MPa, the tensile strength is 1620MPa, the elongation is 16%, and the impact toughness at room temperature is 65J / cm 2 .

Embodiment 3

[0038] For the chemical composition by weight percentage, C: 0.25%, Cr: 16%, Mn: 1.1%, Si: 1.1%, Ni: 1%, Cu: 0.2%, P≤0.02%, S:≤0.02%, The raw material with the balance being iron is smelted in a vacuum induction furnace. After the smelted casting is held at 1180°C for 2 hours, forging begins, and the final forging temperature is 900°C. Then the obtained forging is heated to 1050°C for 4 hours and then quickly taken out of the furnace for water quenching, followed by tempering at 240°C for 4 hours.

[0039] The main metallographic structure of the obtained material is lath martensite structure and nano-carbide precipitation, has excellent strength, plasticity and toughness, and has good corrosion resistance and weldability. The yield strength is 1330MPa, the tensile strength is 1650MPa, the elongation is 16%, and the room temperature impact toughness is 64J / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Room temperature impact toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com