Functional gradient aluminum-based composite material with multilevel gradient structure and preparation method thereof

An aluminum-based composite material and gradient structure technology, applied in the field of composite materials, can solve the problems of low material density, high material density, and short production cycle, and achieve high comprehensive mechanical properties, excellent comprehensive mechanical properties, and short production cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

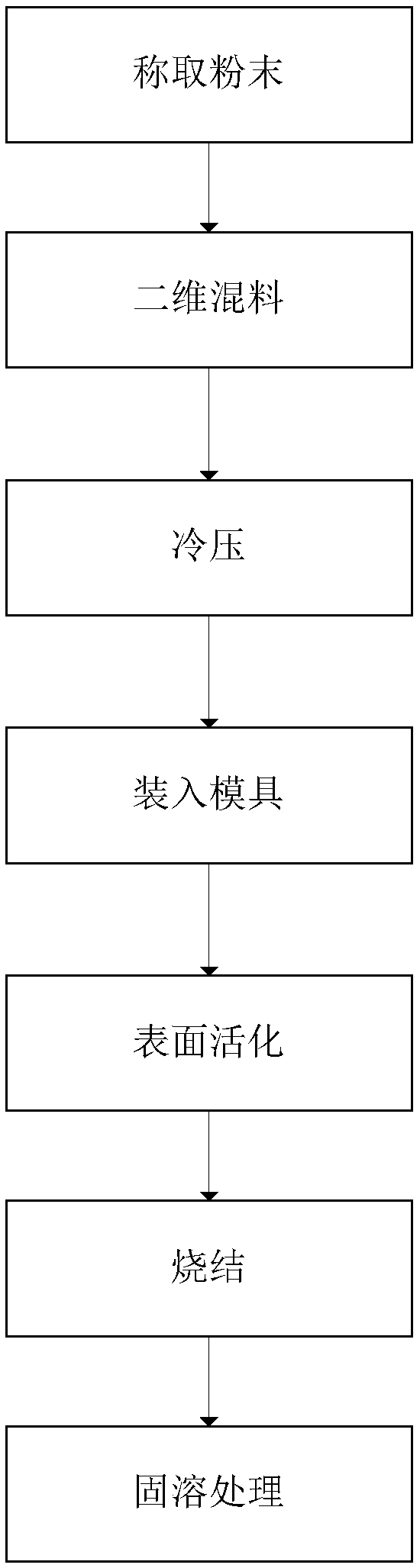

[0038] Please refer to figure 2 , a method for preparing a functionally graded aluminum matrix composite with a multi-level gradient structure, comprising the steps of:

[0039]S1. Design the gradient structure, that is, the number and arrangement of the aluminum matrix composite material layer 2, the content of the reinforcing phase in each layer of the aluminum matrix composite material layer 2 and the thickness of each layer, etc., and weigh each aluminum matrix composite material according to the gradient structure. The precipitation strengthening aluminum alloy powder and boron carbide powder required for the material layer 2, and the deformed aluminum alloy powder required for the deformed aluminum alloy layer 1;

[0040] S2. Perform two-dimensional mixing of the precipitation-strengthening aluminum alloy powder and boron carbide powder weighed in step S1 according to the precipitation-strengthening aluminum alloy powder and boron carbide powder required for the layer 2...

Embodiment 1

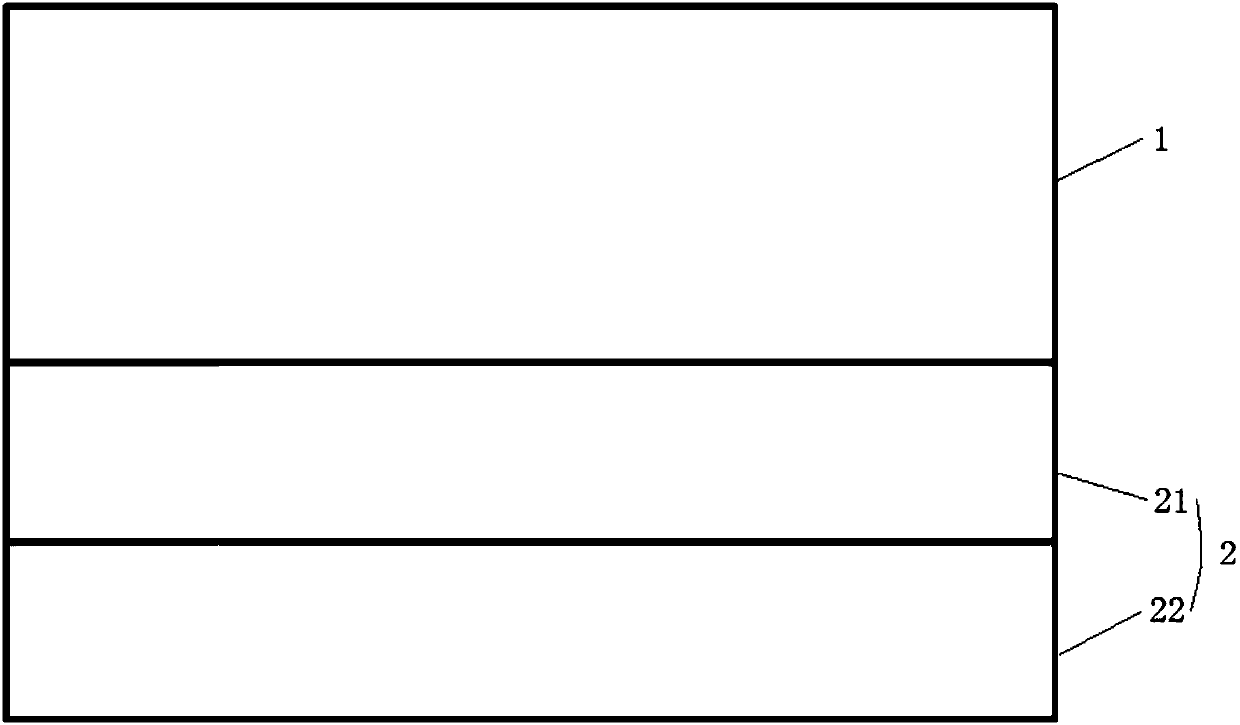

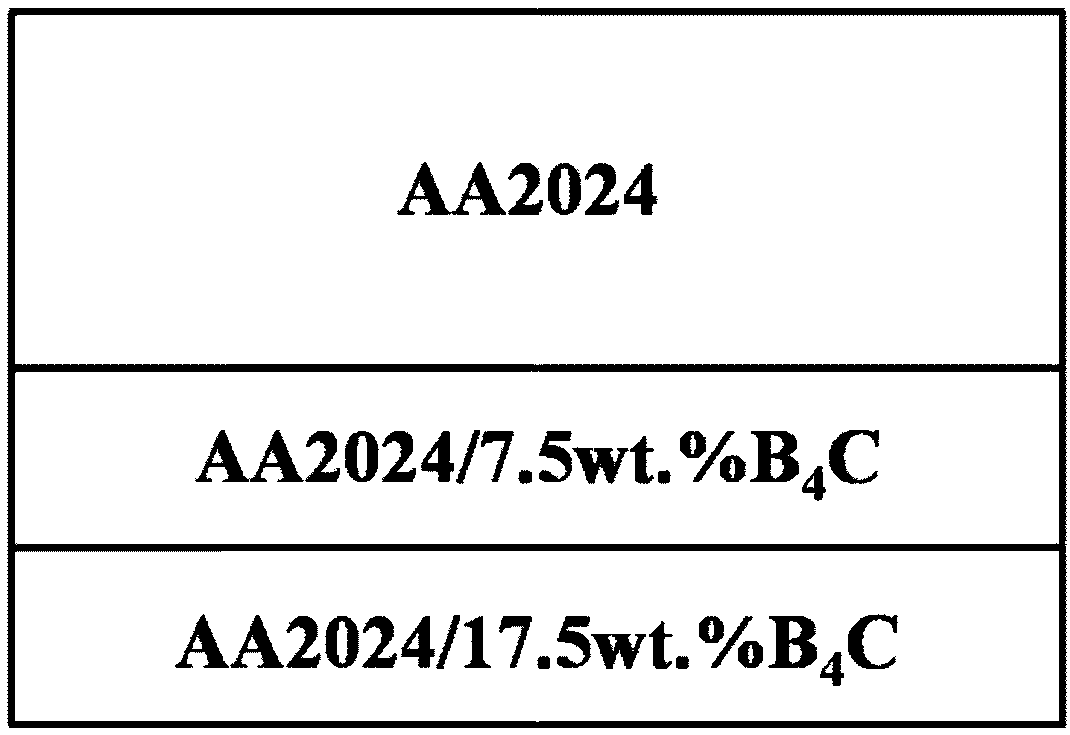

[0047] see figure 1 , a functionally graded aluminum matrix composite material with a multi-level gradient structure: including a deformed aluminum alloy layer 1 and two layers of aluminum matrix composite material layer 2, the components and contents of each layer are AA2024, AA2024 / 7.5wt.%B 4 C. AA2024 / 17.5wt.%B 4 C, the thickness ratio of each layer is 2:1:1, the total thickness is 5.25mm, and the diameter is Ф32mm.

[0048] Preparation:

[0049] A. Weigh the powder:

[0050] Weigh 27.75g, 24.75g of 2024 aluminum alloy powder (particle size is 200 mesh, median diameter is 28.6μm, prepared by aerosol method) and 2.25g, 5.25g of boron carbide powder (purity ≥ 99% , particle size is 4μm);

[0051] B. Two-dimensional mixing:

[0052] Mix 2024 aluminum alloy powder and boron carbide powder according to the requirements of different aluminum matrix composite material layers to obtain AA2024 / 7.5wt.%B 4 C and AA2024 / 17.5wt.%B 4 C, the weighed 30g AA2024 / 7.5wt.%B 4 C and 30g...

Embodiment 2

[0071] see figure 1 , a functionally graded aluminum matrix composite material with a multi-level gradient structure: including a deformed aluminum alloy layer 1 and two layers of aluminum matrix composite material layer 2, the components and contents of each layer are AA2024, AA2024 / 7.5wt.%B 4 C, AA2024 / 12.5wt.%B 4 C, the thickness ratio of each layer is 1:1:1, the total thickness is 5.45mm, and the diameter is Ф32mm.

[0072] Preparation:

[0073] A. Weigh the powder:

[0074] Weigh 27.75g, 24.75g of 2024 aluminum alloy powder (particle size is 200 mesh, median diameter is 28.6μm, prepared by aerosol method) and 2.25g, 5.25g of boron carbide powder (purity ≥ 99% , particle size is 4μm);

[0075] B. Two-dimensional mixing:

[0076] Mix 2024 aluminum alloy powder and boron carbide powder according to the requirements of different aluminum matrix composite material layers to obtain AA2024 / 7.5wt.%B 4 C, AA2024 / 12.5wt.%B 4 C, the weighed 30g AA2024 / 7.5wt.%B 4 C and 30gAA2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com