High-strength and high-elasticity titanium-copper alloy and preparation method thereof

A high-elasticity, titanium-copper technology, which is applied in the field of high-strength and high-elasticity titanium-copper alloys and their preparation, can solve the problems that the tensile strength, hardness and elongation of titanium bronze cannot be satisfied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

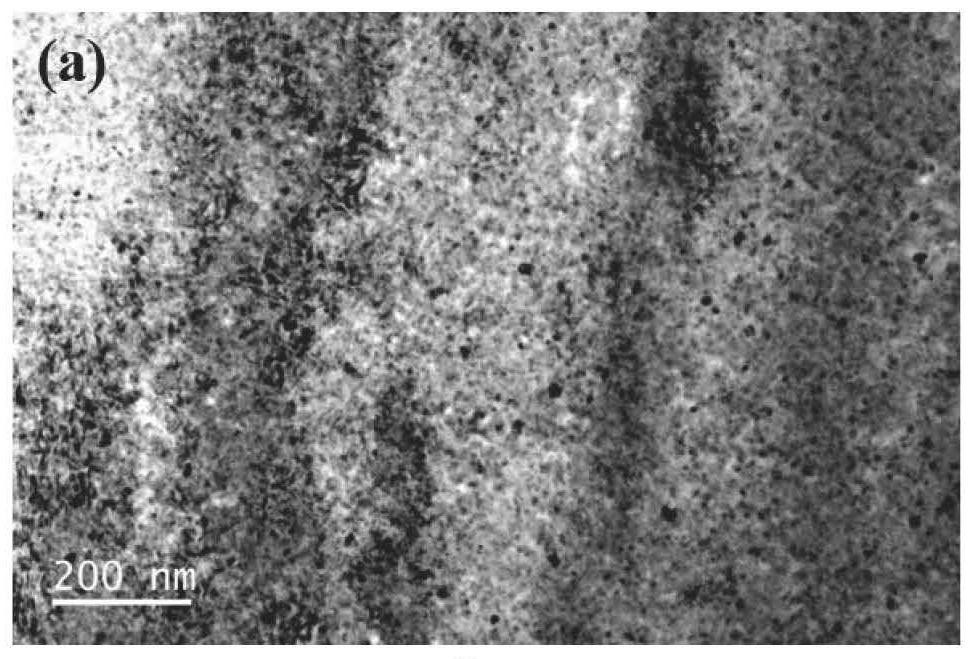

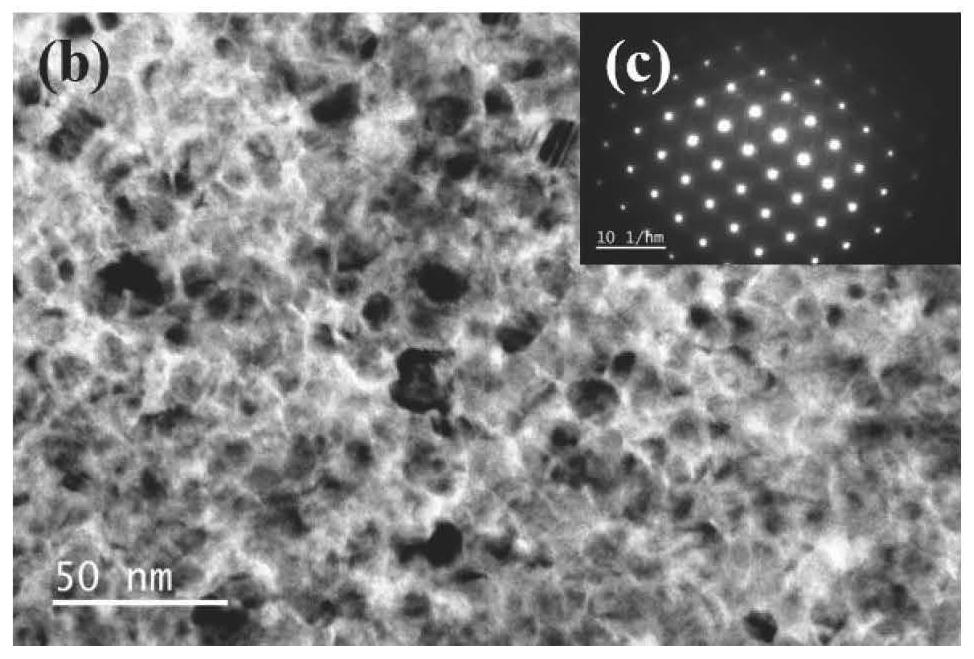

Image

Examples

preparation example Construction

[0028] The present invention provides a method for preparing the high-strength and high-elasticity titanium-copper alloy according to the above technical solution, which comprises the following steps:

[0029] (1) casting after the alloy raw material is smelted to obtain an alloy ingot;

[0030] (2) forging, hot rolling and cold rolling are carried out successively to the alloy ingot obtained in the step (1) to obtain a rolled alloy;

[0031] (3) The rolled alloy obtained in the step (2) is sequentially subjected to bell annealing, finishing rolling, continuous annealing, pre-finishing, solution treatment, finishing rolling, aging treatment and stretch-bending straightening to obtain high strength High elastic titanium copper alloy.

[0032] In the present invention, the alloy raw material is smelted and then casted to obtain an alloy ingot.

[0033] In the present invention, the alloy raw material preferably includes microalloy raw material, electrolytic copper, copper-tita...

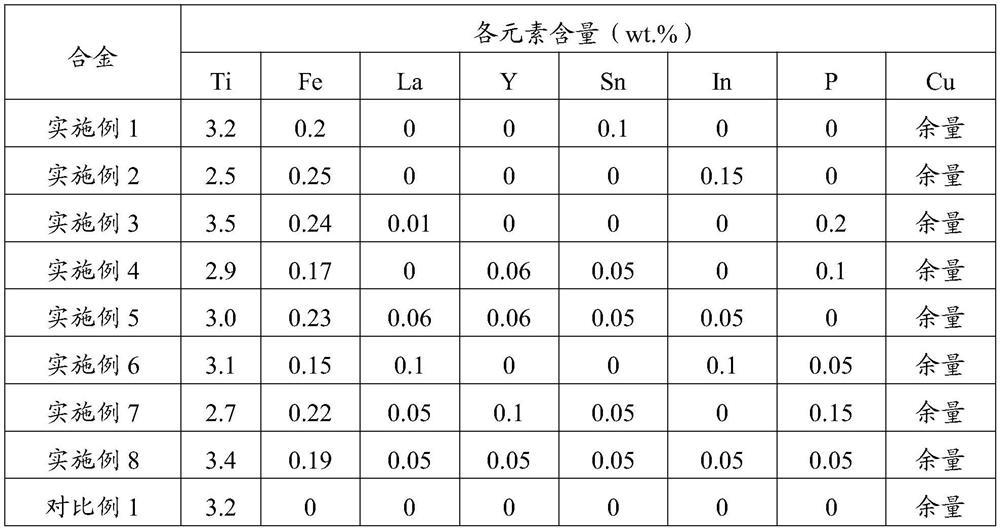

Embodiment 1

[0075] A high-strength and high-elasticity titanium-copper alloy, in terms of mass percentage, is composed of: Ti: 3.2%, Fe: 0.2%, Sn: 0.1%, and the balance of Cu;

[0076] The preparation method of the high-strength and high-elasticity titanium-copper alloy comprises the following steps:

[0077](1) after the alloy raw material is smelted, carry out side drainage casting to obtain an alloy ingot, and the alloy raw material is electrolytic copper, Cu-50%Ti master alloy, industrial pure iron and pure Sn; the temperature of the smelting is 1300 ℃ ℃; the vacuum degree of the smelting is 5×10 -2 Pa;

[0078] (2) Forging the alloy ingot obtained in the step (1) at 850°C (the forging method is to forge two times on one side, then turn 180° and continue forging for two times), and then heat the ingot at 800°C for 2 hours. Rolling (the initial rolling temperature of hot rolling is 800 °C, the final rolling temperature of hot rolling is 530 °C, and the total processing rate of hot ro...

Embodiment 2

[0087] A high-strength and high-elasticity titanium-copper alloy, in terms of mass percentage, is composed of: Ti: 2.5%, Fe: 0.25%, In: 0.15%, and the balance of Cu;

[0088] The preparation method of the high-strength and high-elasticity titanium-copper alloy comprises the following steps:

[0089] (1) after the alloy raw material is smelted, carry out side drainage casting to obtain an alloy ingot, and the alloy raw material is electrolytic copper, Cu-50%Ti master alloy, industrial pure iron and pure In; the temperature of the smelting is 1300 ℃ ℃; the vacuum degree of the smelting is 5×10 -2 Pa;

[0090] (2) Forging the alloy ingot obtained in the step (1) at 900°C (the forging method is to forge two times on one side, then turn 180° and continue forging for two times), and then heat the ingot at 750°C for 4 hours. Rolling (the initial rolling temperature of hot rolling is 750 °C, the final rolling temperature of hot rolling is 520 °C, and the total processing rate of hot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com