Composite modifier for copper alloy of lead frame

A compound modificator and lead frame technology, applied in the field of copper alloy processing, can solve the problems of backward technical level, restricting the production and development of electronic information industry, semiconductor and integrated circuit packaging industry, etc., achieve scientific and reasonable formula, improve high temperature mechanical properties, The effect of improving the quality of slab

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

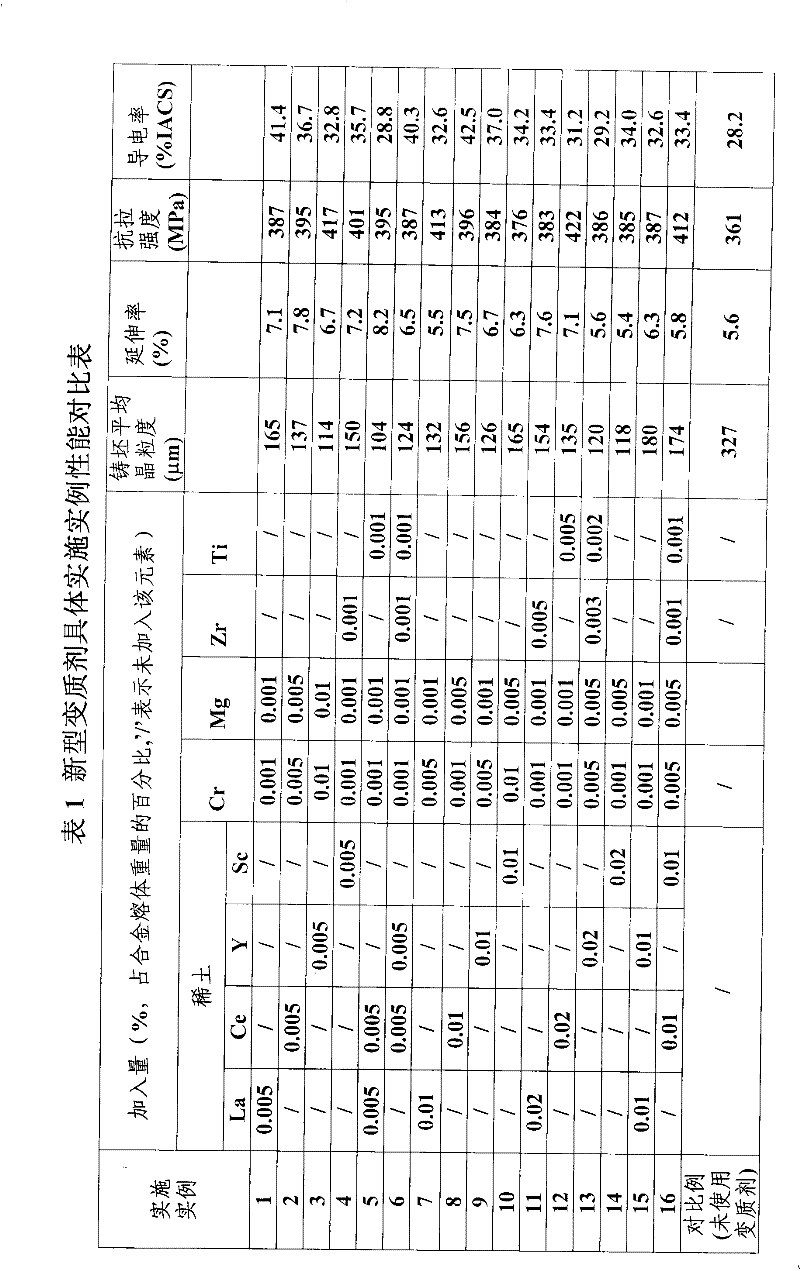

[0023] The following uses 16 implementation examples of the present invention (as shown in Table 1) to further illustrate the excellent performance of the present invention.

[0024] The production and processing technology is ingredients-semi-continuous ingot-milling-heating-hot rolling billeting-pickling-solution treatment-cold rolling-aging treatment-finishing rolling-stress relief annealing-finished product.

[0025] The casting experiment adopts 500KW intermediate frequency induction furnace and continuous casting equipment, and adopts the method of pouring the melt to the tundish to carry out the large ingot semi-continuous casting experiment. First melt the red copper, then add Cu-Fe, Cu-Zn master alloys, keep warm after melting, then add the pre-configured modifiers Cu-RE, Cu-Cr, Cu-Mg and other master alloys, stir for 10-15 minutes, Keep the temperature for 30-50 minutes, add Cu-P master alloy, pouring, and then perform milling and rolling processes to obtain the final pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com