High-entropy alloy reinforced aluminum-based composite material and preparation method thereof

An aluminum-based composite material and high-entropy alloy technology, which is applied in the field of composite materials to achieve the effects of high hardness elongation, uniform particle distribution, and high interface bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

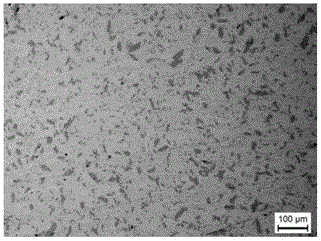

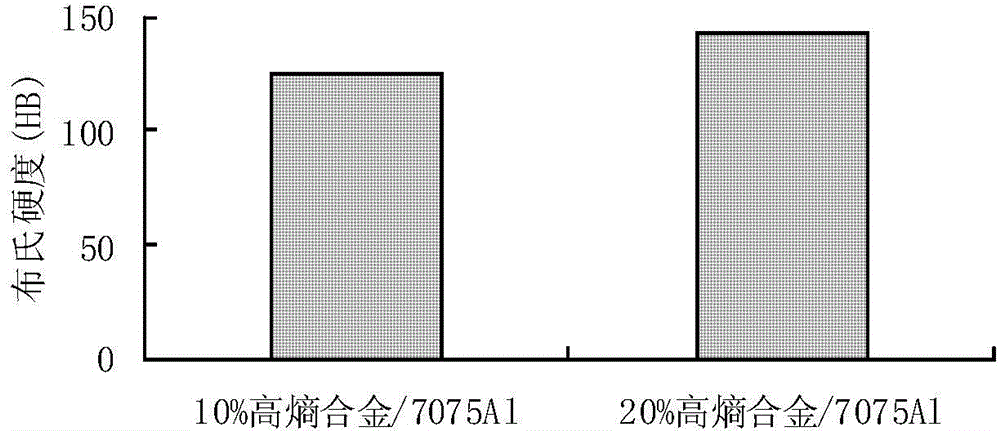

Embodiment 1

[0028] (1) Mixed powder: AlCrFeNiCoTi series high-entropy alloy particles are selected as the reinforcing phase, the composition is Al0.25CrFeNiCoTi0.75, the average particle size is 30 μm, and the volume fraction is 10%. In this example, the high-entropy alloy particles were prepared by mechanical alloying process, using a planetary ball mill for mechanical alloying, the rotation speed was ≥250rpm, the ball milling time was 50 hours, and the ball-to-material ratio was 15:1. The aluminum alloy matrix is 7075Al in the 7xxx series alloy, and its volume fraction is 90%; the corresponding weight of high-entropy alloy particles and aluminum alloy powder is weighed out with an electronic balance, put into a ball mill jar and sealed, and then dry Mixing method Mix powder for 10 hours;

[0029] (2) Sheath billet making: put the Al0.25CrFeNiCoTi0.75 high-entropy alloy particles and 7075Al powder into the aluminum alloy sheath after the powder mixing is completed, and compact the powd...

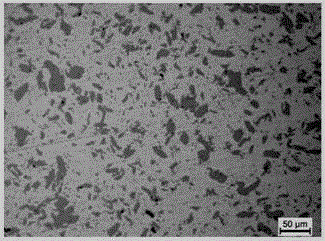

Embodiment 2

[0033] (1) Mixed powder: AlCrFeNiCoTi series high-entropy alloy particles are selected as the reinforcing phase. The specific composition of the high-entropy alloy is Al0.25CrFeNiCoTi0.75, the average particle size is 30 μm, and the volume fraction is 20%. In this example, the high-entropy alloy particles were prepared by mechanical alloying process, using a planetary ball mill for mechanical alloying, the rotation speed was ≥250rpm, the ball milling time was 50 hours, and the ball-to-material ratio was 15:1. The aluminum alloy matrix is 7075Al in the 7xxx series alloy, and its volume fraction is 80%; the corresponding weight of high-entropy alloy particles and aluminum alloy powder is weighed out with an electronic balance, put into a ball mill jar and sealed, and then dry Mixing method Mix powder for 15 hours;

[0034] (2) Sheath billet making: put the Al0.25CrFeNiCoTi0.75 high-entropy alloy particles and 7075Al powder into the aluminum alloy sheath after the powder mixing...

Embodiment 3

[0038](1) Mixed powder: AlCrFeNiCoTi series high-entropy alloy particles are selected as the reinforcing phase. The specific composition of the high-entropy alloy is Al0.5CrFeNiCoTi0.5, the average particle size is 30 μm, and the volume fraction is 25%. In this example, the high-entropy alloy particles were prepared by mechanical alloying process, using a planetary ball mill for mechanical alloying, the rotation speed was ≥250rpm, the ball milling time was 50 hours, and the ball-to-material ratio was 15:1. The aluminum alloy matrix is 6061Al in the 6xxx series alloy, and its volume fraction is 75%; the corresponding weight of high-entropy alloy particles and aluminum alloy powder is weighed out with an electronic balance, put into a ball mill jar and sealed, and then dry Mixing method Mix powder for 12 hours;

[0039] (2) Sheath billet making: put the Al0.5CrFeNiCoTi0.5 high-entropy alloy particles and 6061Al powder after powder mixing into the aluminum alloy sheath, and use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com