Method, device and system for preparing tritium

An optional, cavitation technology, applied in the fields of tribology and nuclear physics, can solve problems such as reactor safety issues, high construction costs, and reduced production capacity, so as to improve safety, reduce the risk of nuclear proliferation, and improve safety high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

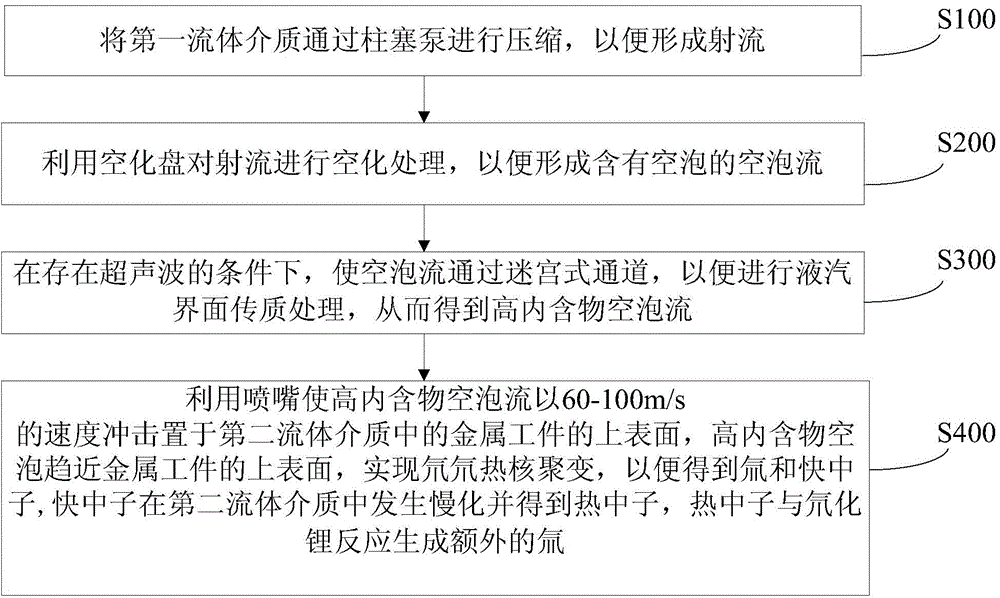

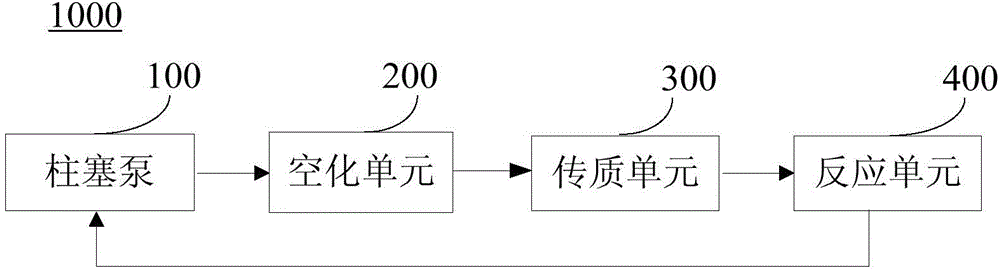

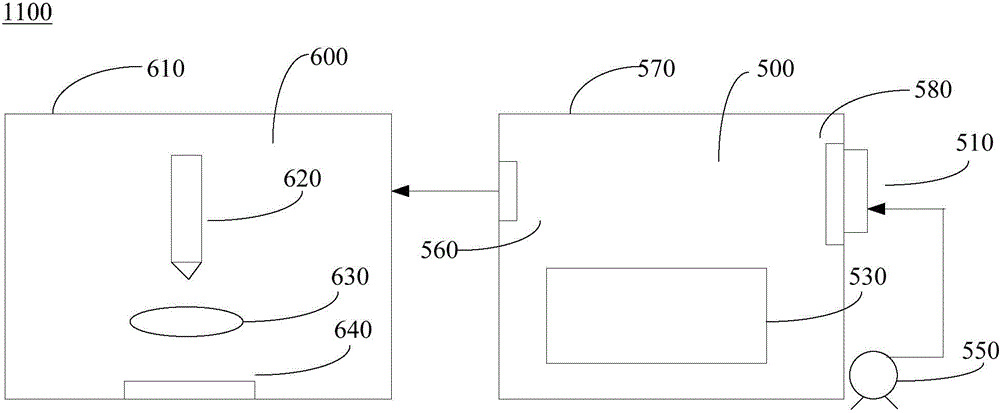

[0089] use Figure 4 The described device contains 3mmol / l 6 LiD heavy water is the first fluid medium, and heavy water containing 1.8 mmol / L sodium lauryl sulfate is the second fluid medium for preparing tritium. The water level of the second fluid medium in the reaction assembly 600 is as high as image 3 The water level line A is shown, and the specific preparation process is as follows:

[0090] (1) Will contain 3mmol / l 6 The heavy water of LiD is provided with a high-pressure, high-speed heavy water jet by the plunger pump 550, and the pressure of the jet is in the range of 10-15 atmospheres.

[0091] (2) The heavy water jet enters the device through the inlet 510, and is processed by the cavitation disk 580 to generate microcavitations, forming a cavitation flow, and entering the mass transfer space of large volume. The partition divides the mass transfer space into the upper fluid medium area and In the lower ultrasonic generating area, the cavitation flow flows in the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com