Embedded glow discharge electrode

A glow discharge and embedded technology, which is applied to the installation/support/configuration/insulation of discharge tube/lamp components, circuits, and electrode assemblies, and can solve problems such as occupying effective space, water leakage, and high-fusion experimental reactors , to achieve the effects of improving safety and reliability, reducing the risk of water leakage, and reducing the concentration of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

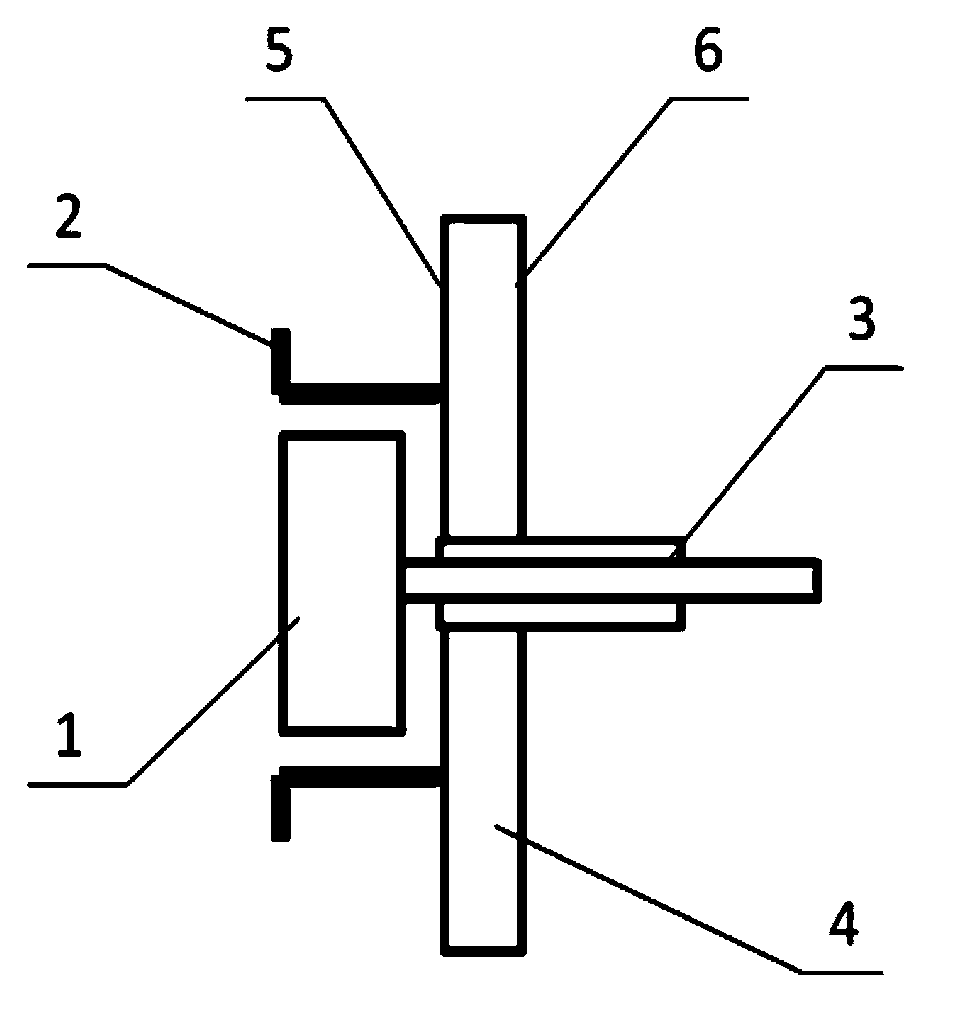

[0012] The embedded glow discharge electrode provided by the present invention is composed of an electrode head 1 , a shielding case 2 , a vacuum electric lead wire 3 and a vacuum flange 4 . The vacuum side 5 of the vacuum electrical lead 3 is provided with an electrode head 1 and a shielding case 2 with one side open, and the electrode head 1 is located in the shielding case 2 . One end of the vacuum side 5 of the vacuum electrical lead 3 is connected to the electrode head 1 , and one end of the vacuum electrical lead 3 runs through the vacuum flange 4 to the air side 6 .

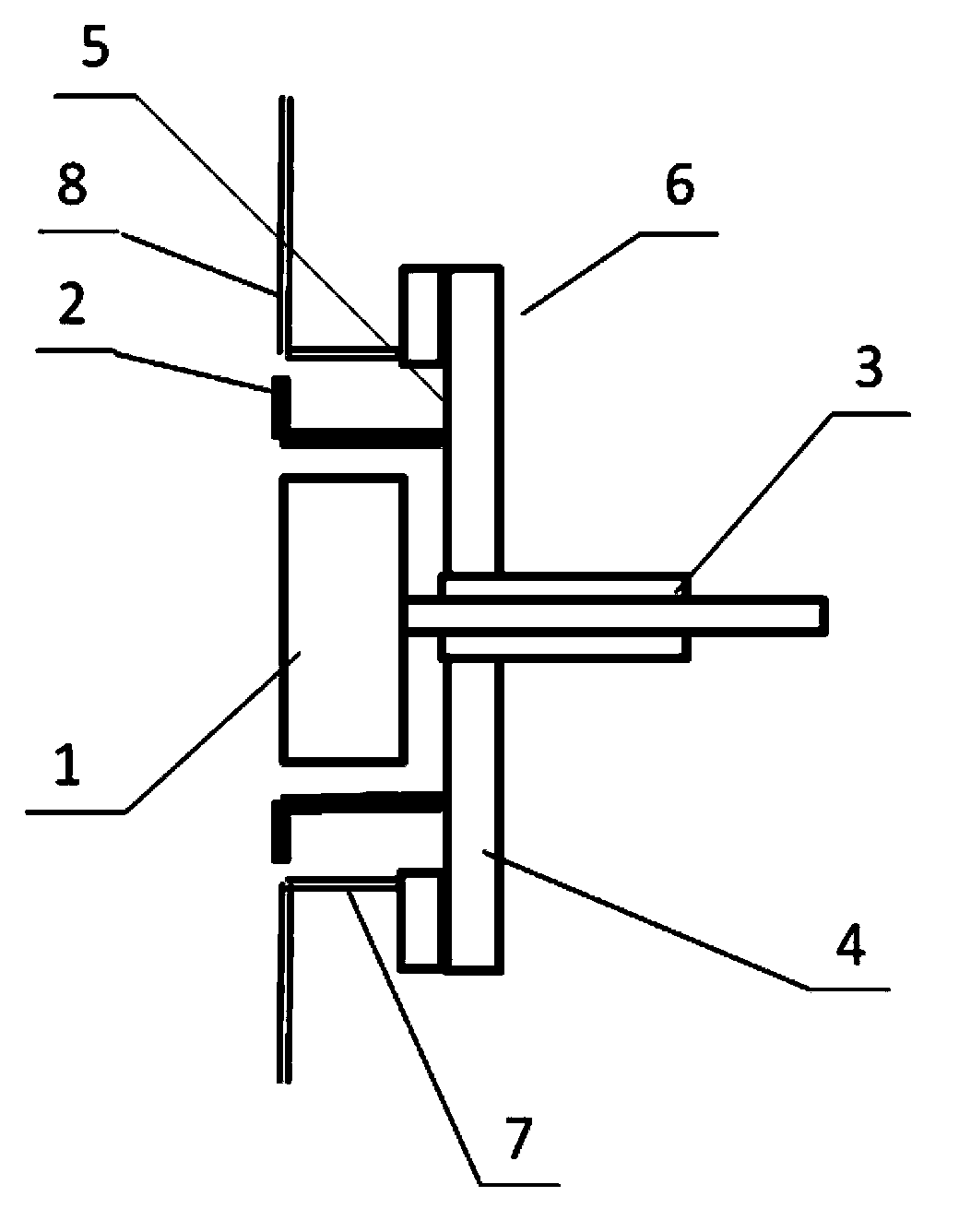

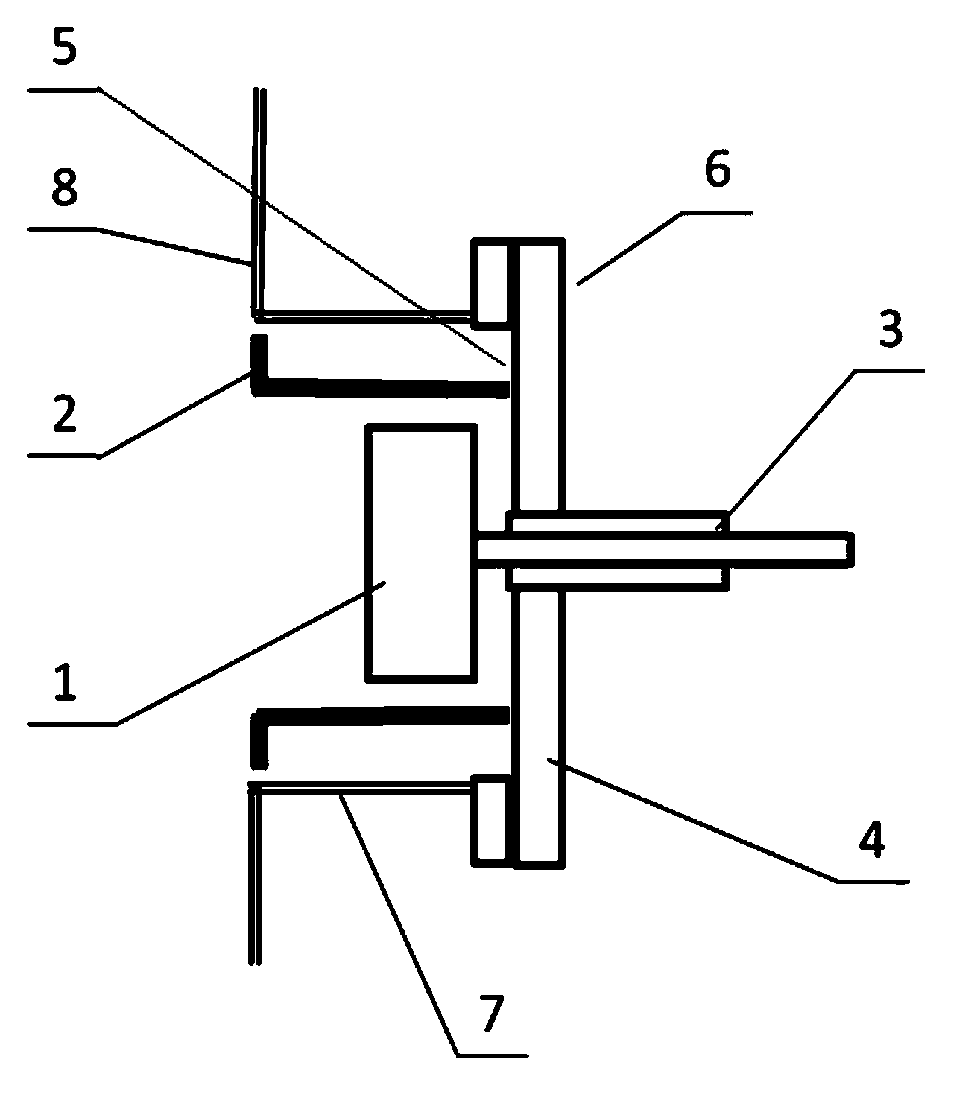

[0013] Such as figure 2 As shown, the shielding cover 2 and the electrode head 1 are inserted into the vacuum window pipe 7 of the fusion experiment reactor vacuum chamber, the vacuum flange 4 is attached to the outside of the vacuum window pipe 7, and the electrode surface on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com