Front cylinder assembly, camera with front cylinder assembly and monitoring system with camera

A front tube and component technology, applied in the field of cameras, can solve the problem of inability to meet complex and harsh environments, and achieve the effects of reducing the risk of equipment leakage, compact structure and space saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

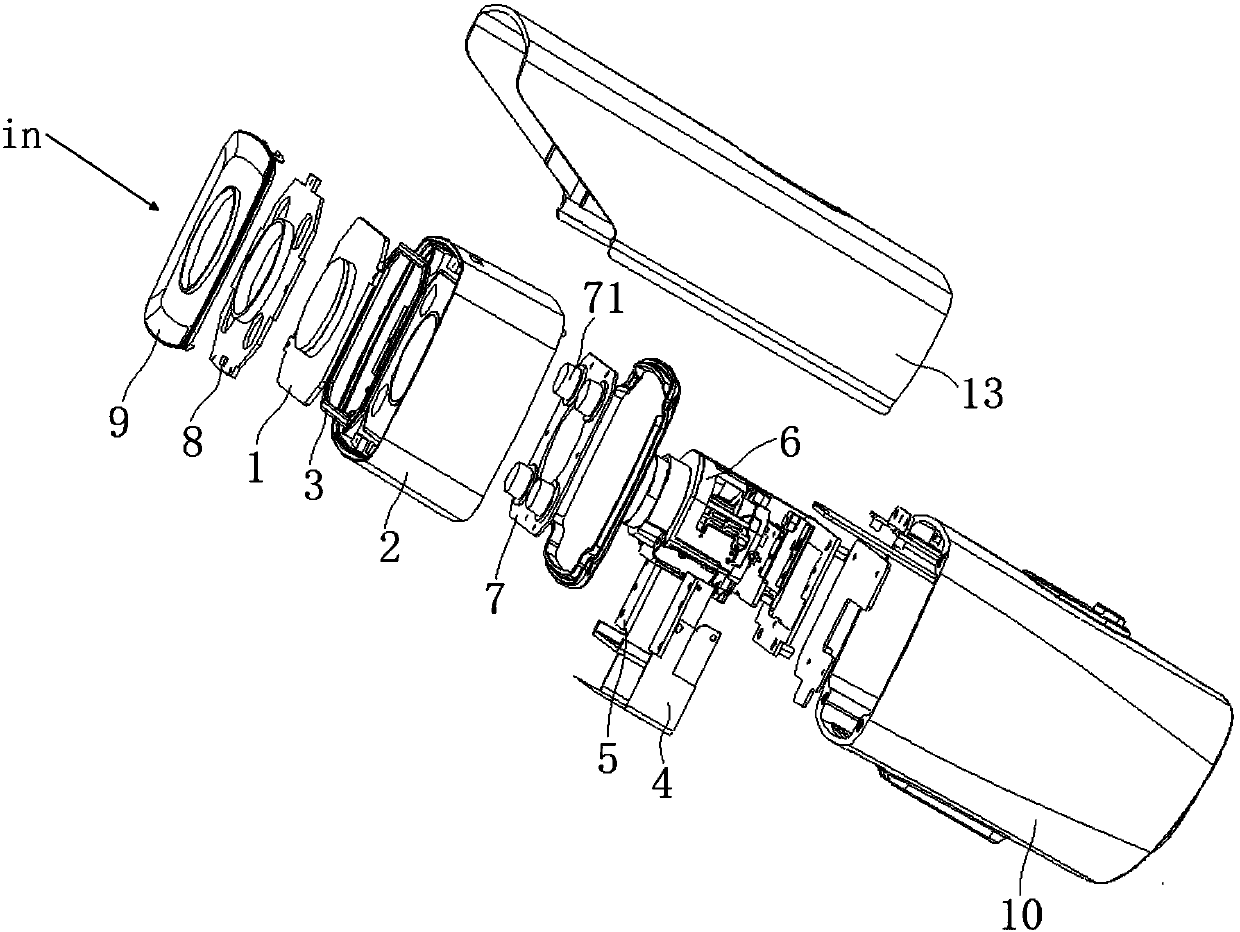

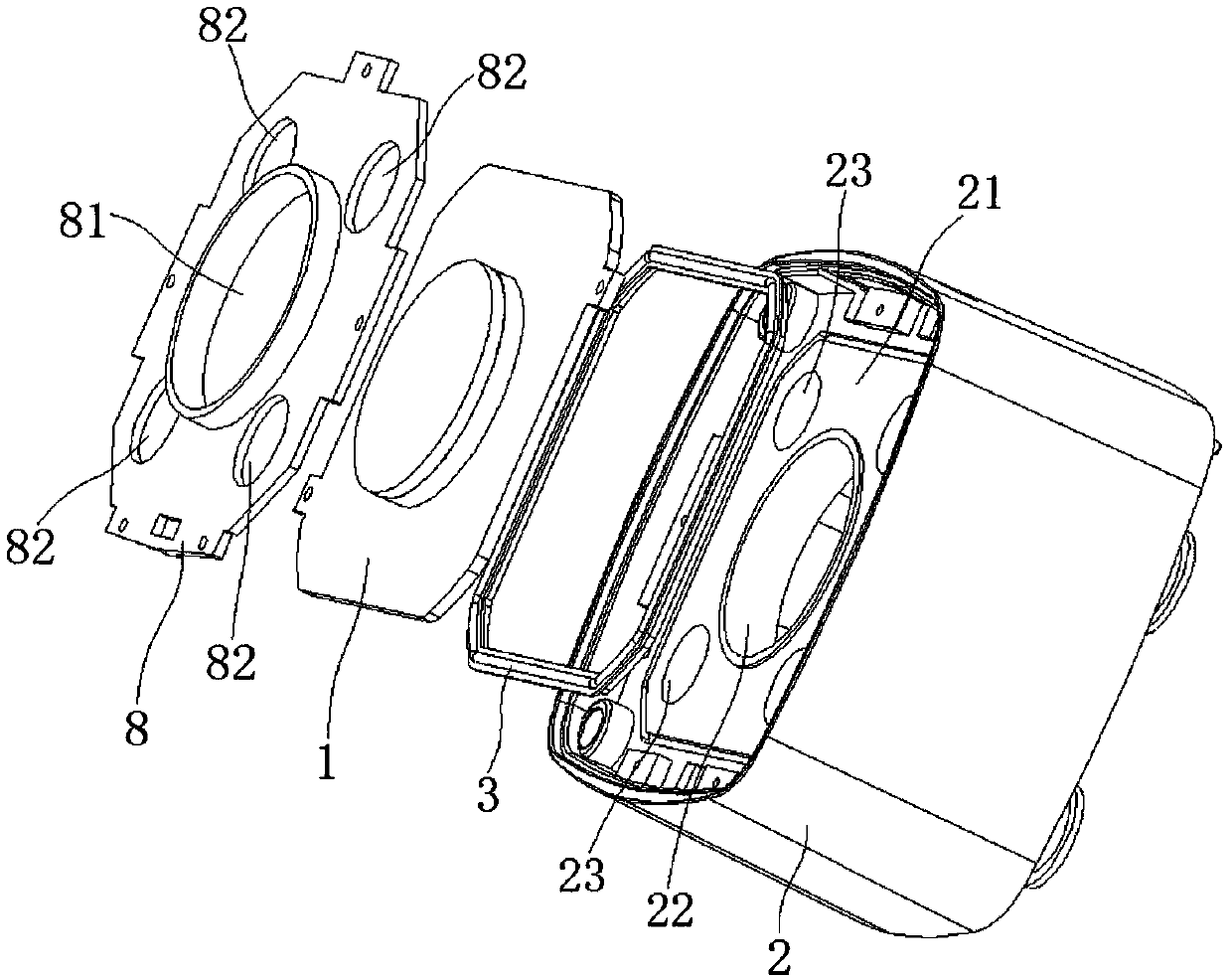

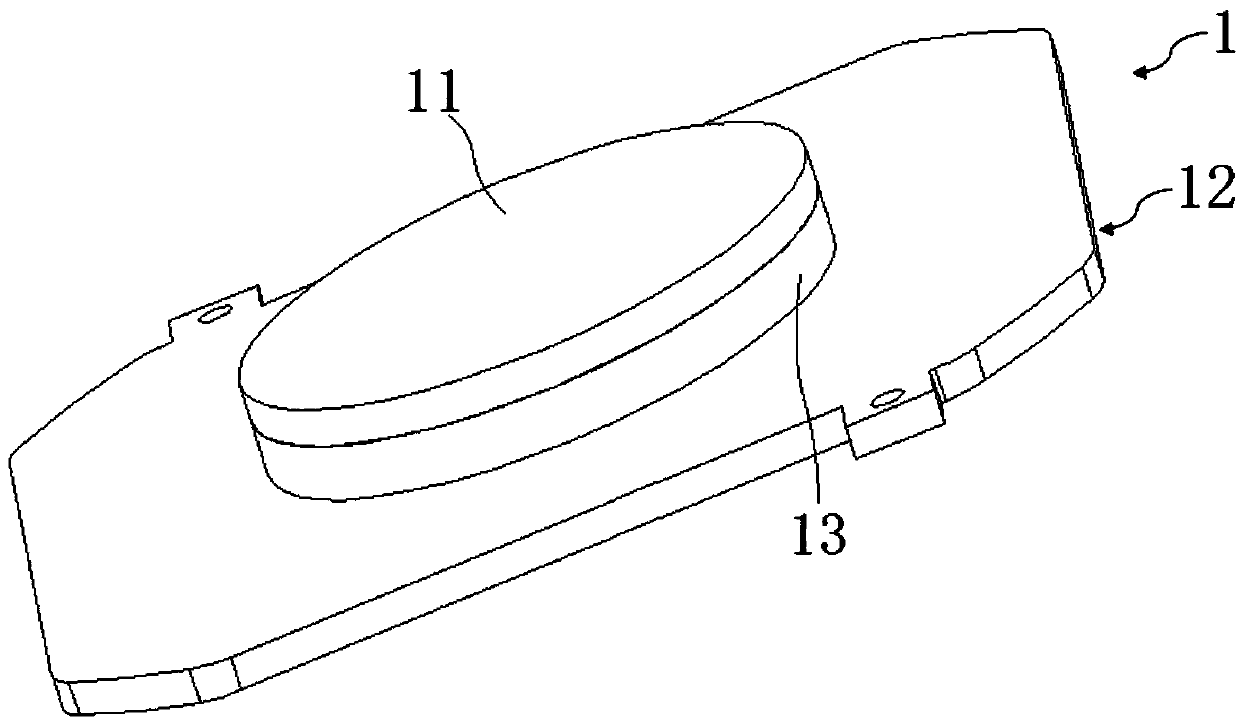

[0037] The video camera includes a barrel body composed of a front barrel assembly and a rear barrel assembly connected to provide a sealed machine cavity. The top of the fuselage is fixedly provided with a sunshield 13, which is not only waterproof and sun-proof, but also makes the overall appearance of the camera more attractive. Wherein: the front cylinder assembly includes the front cylinder 2 and the infrared transparent cover 9, the transparent cover assembly and the supplementary light element 7 arranged in the front cylinder 2 and axially from front to back, and the rear cylinder assembly includes the rear cylinder 10 and the rear cylinder 10. The lens assembly 6 in the barrel 10 , the lens assembly 6 includes a lens 61 . The lens assembly 6 and the supplementary light element 7 are arranged downstream of the transparent cover assembly.

[0038] In the present invention, "front" and "back" are determined according to the direction of the light, usually the light is fr...

Embodiment 2

[0057] Figure 8 The schematic camera includes a barrel body formed by connecting a front barrel assembly and a rear barrel assembly to provide a sealed machine cavity. The top of the fuselage is fixedly provided with a sunshade 13', which not only can prevent water and sun exposure, but also makes the overall appearance of the camera more attractive. Among them: the front tube assembly includes the front tube 2' and the infrared transparent cover 9' located in the middle 2' of the front tube 2' and axially from front to back, a transparent cover component and a supplementary light element, and the rear tube component includes the rear tube 10' and a lens assembly 6' disposed in the rear barrel 10', the lens assembly 6' includes a lens 61'. The lens assembly 6' and the supplementary light element 7' are arranged downstream of the transparent cover assembly.

[0058] In the present invention, "front" and "back" are determined according to the direction of the light, usually t...

Embodiment 3

[0073] Figure 10 The schematic camera includes a barrel body formed by connecting a front barrel assembly and a rear barrel assembly to provide a sealed machine cavity. The top of the fuselage is fixed with a sunshade 13", which not only prevents water and sun exposure, but also makes the overall appearance of the camera more beautiful. Among them: the front tube assembly includes the front tube 2" and is located in the front tube 2" and 2" along the Axially from front to back, the infrared transparent cover 9", the transparent cover assembly and the supplementary light element, the rear barrel assembly includes a rear barrel 10" and a lens assembly 6" arranged in the rear barrel 10", and the lens assembly 6" includes a lens. The lens assembly 6" and the supplementary light element 7" are arranged downstream of the transparent cover assembly.

[0074] In the present invention, "front" and "back" are determined according to the direction of the light, usually the light is fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com