Low temperature superconducting assembly with low joint resistance for high temperature superconducting current lead cold end

A current lead, low-temperature superconducting technology, applied in superconducting magnets/coils, electrical components, connecting contact materials, etc., can solve problems such as easy leakage and difficult to repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

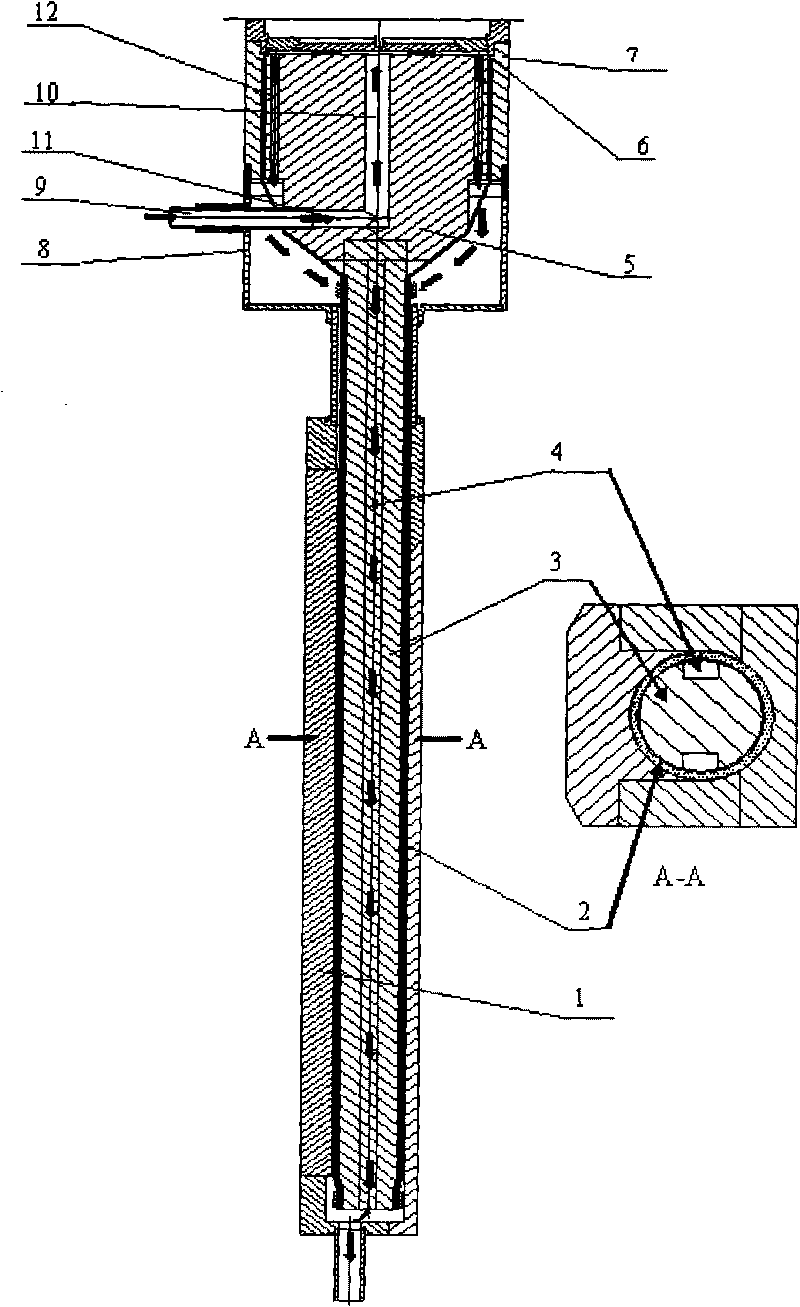

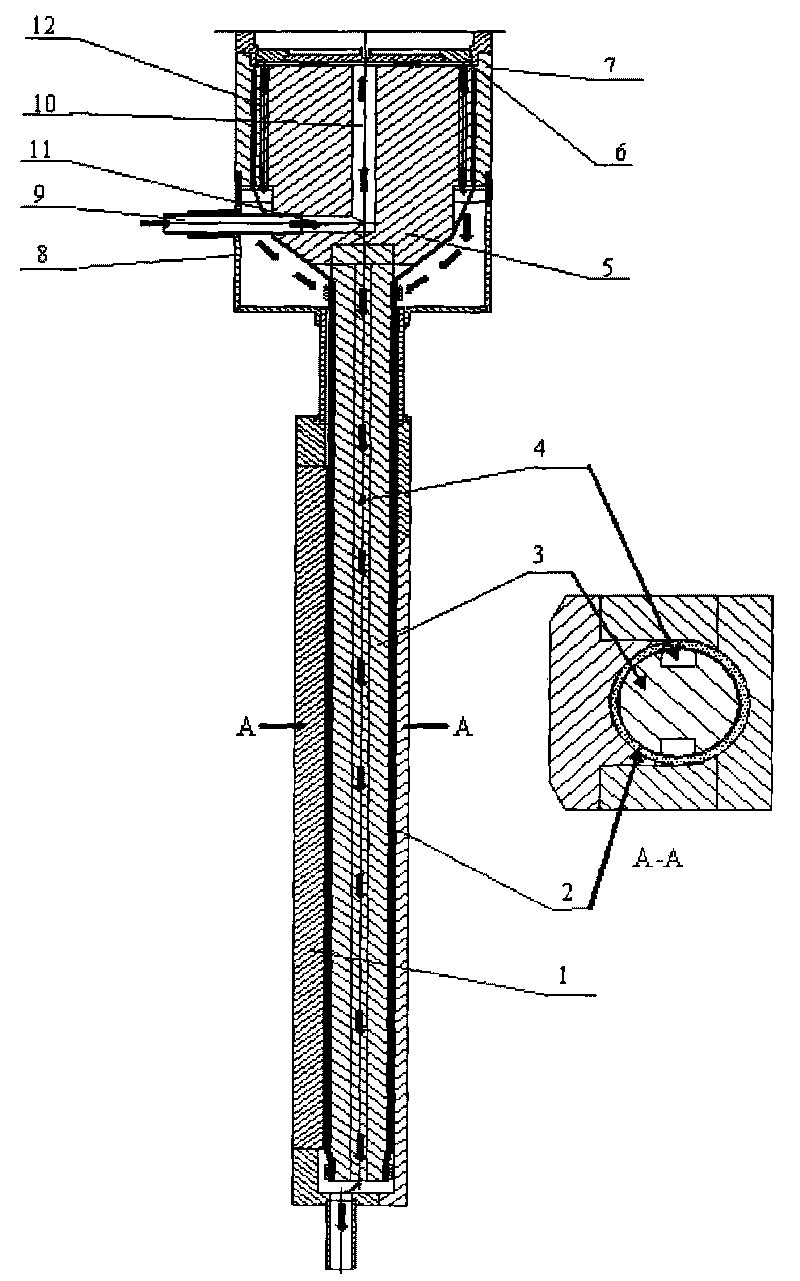

[0032] A low-temperature superconducting component used for the cold end of high-temperature superconducting extra-large current leads and low joint resistance, specifically a joint box 1, the joint box 1 is composed of a base and a cover plate, and the base and cover plate are made of copper plate and stainless steel The board is integrated by explosive welding, and there is a semicircular groove on the copper layer of the base and the cover; the cross-sectional area is 1×2.7mm 2 Rectangular niobium-titanium superconducting wire bundle 2, the number is 90, the spiral narrow side is wrapped around the copper rod 3, and the side wall of the copper rod 3 has a groove 4; the base of the rectangular niobium-titanium superconducting wire 2 and the joint box 1 is connected with The surface of the copper plate layer of the cover plate is hot-plated with Sn-40Pb solder in advance, and no flux remains, and then the rectangular niobium-titanium superconducting wire bundle 2 and the coppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com