Cable with processed conducting wire core specially for winding

A technology of conductive wire core and cable, applied in the direction of transformer/inductor coil/winding/connection, insulating conductor/cable, insulating cable, etc., can solve problems such as large eddy current loss, and achieve the effect of reducing AC loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

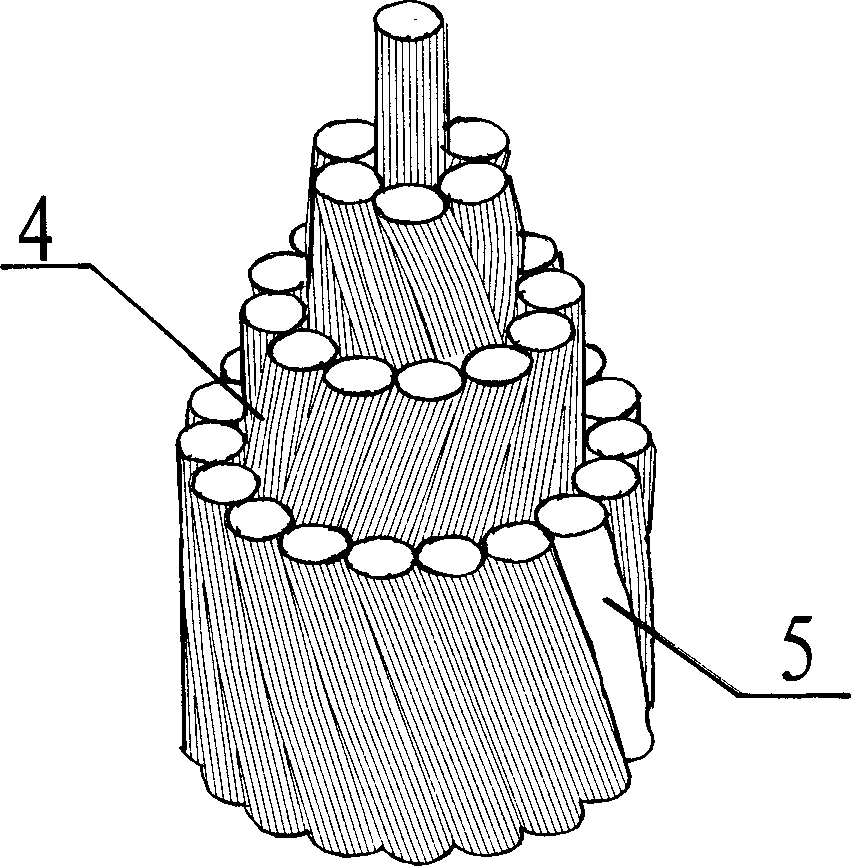

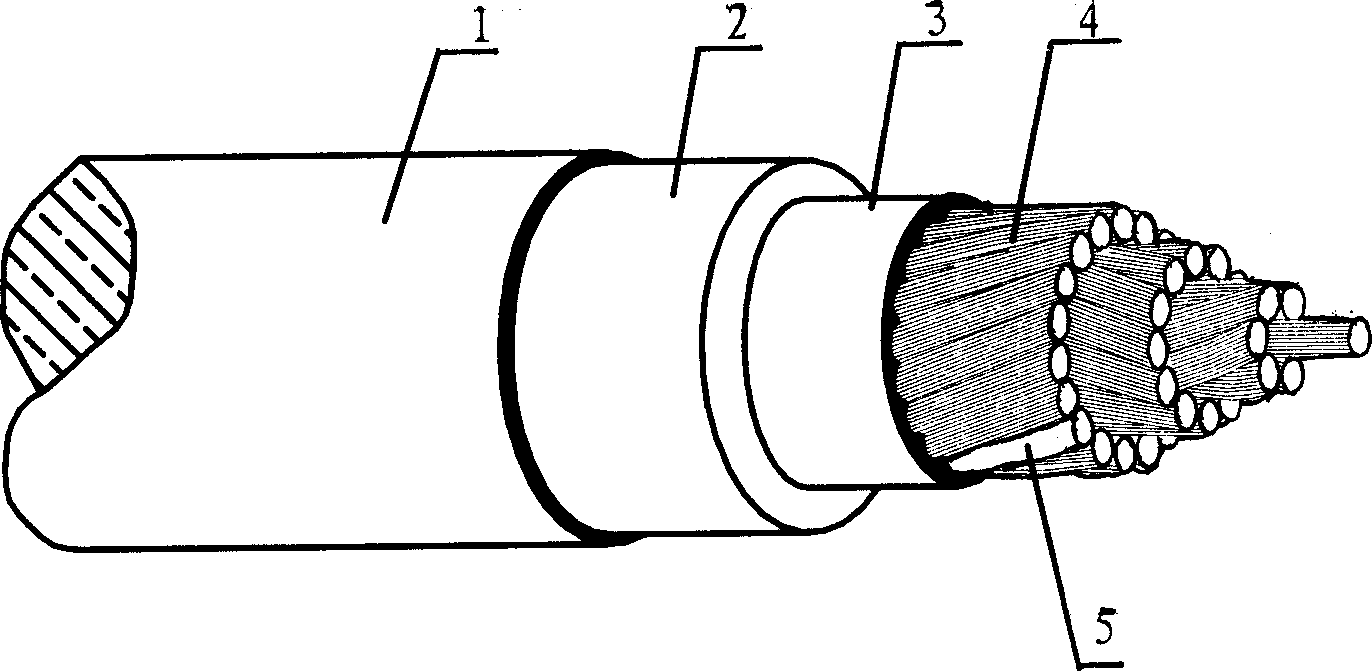

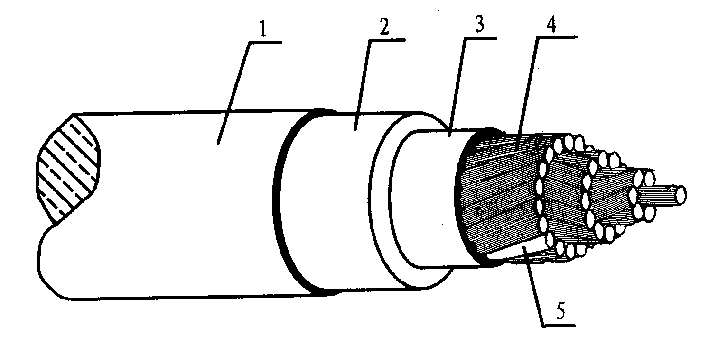

[0009] In order to ensure uniform potential, at least one untreated conductive core (5) in the outermost conductive core of the conductor (4) containing a thinner copper oxide insulating layer is reliably electrically connected to the inner semiconductive layer (3). Contact to ensure the unity of potential.

[0010] For example, the treated stranded conductive wire core is treated with the last drawing die (diameter unchanged), and then the inner semiconductive layer (3), insulating layer (2), outer The semi-conductive layer (1), so that at least one untreated conductor (5) on the outermost layer of the twisted conductive wire core is in reliable electrical contact with the inner semi-conductive layer (3), and the potential is kept uniform.

[0011] The present invention uses a low-viscosity mixed solution of 1% to 10% by weight of sodium chlorite and 1% to 10% of sodium hydroxide to soak and chemically treat the conductive wire core, and after this treatment, each single core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com