High-temperature superconducting composite conductor containing inner superconducting layer and outer superconducting layer

A composite conductor, high-temperature superconducting technology, applied in the directions of superconducting/high-conducting conductors, the usage of superconducting elements, superconducting devices, etc. Current-carrying performance, improved fill factor, powerful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

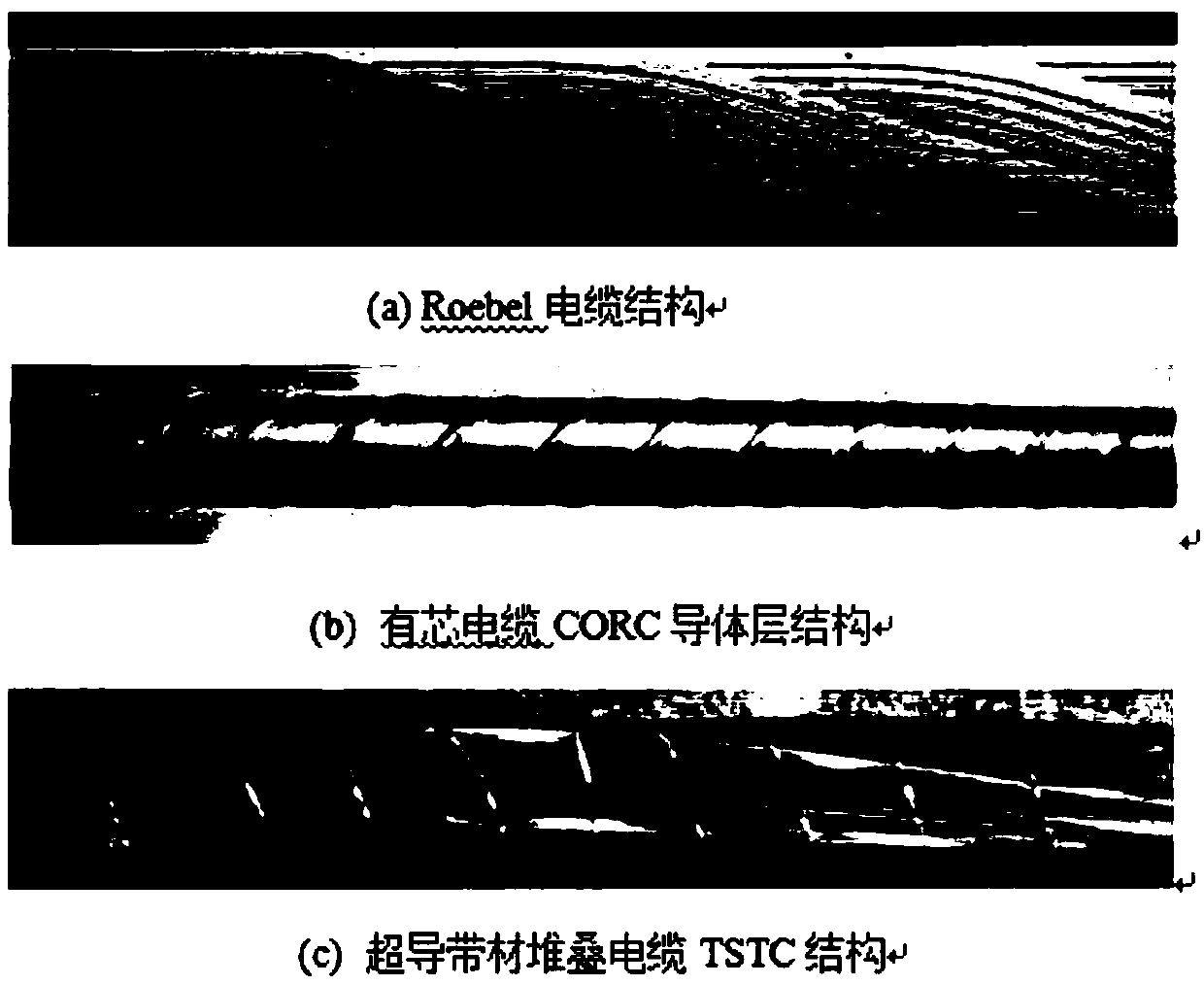

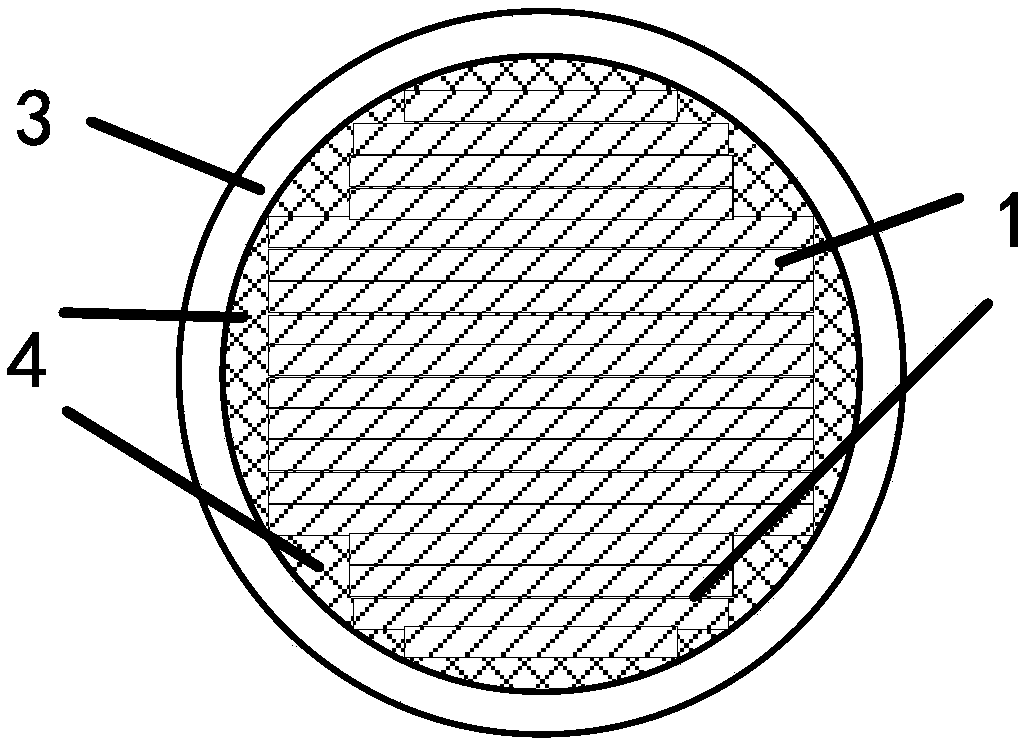

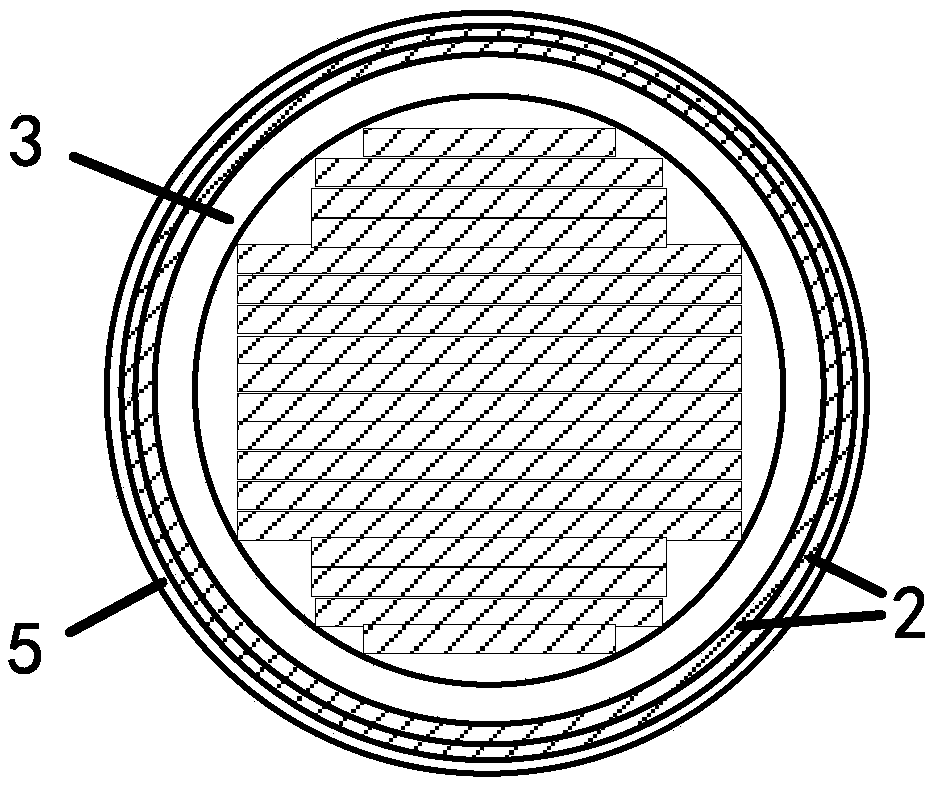

[0029] like Figure 2~3 Shown is a schematic diagram of the inner superconducting layer and the outer superconducting layer of the superconducting composite conductor provided by the present invention.

[0030] The superconducting composite conductor includes an inner superconducting layer and an outer superconducting layer; the inner superconducting layer includes an inner superconducting layer unit and a filling factor arranged in the metal skeleton; the outer superconducting layer unit includes an outer superconducting layer wound on the metal skeleton The insulating layer outside the conducting unit and the outer superconducting unit.

[0031] like figure 2 Shown is a schematic diagram of the inner superconducting layer of the superconducting composite conductor provided by the present invention. The inner superconducting layer unit is a parallel structure of multiple high-temperature superconducting strips twisted along the length direction according to a specific pitch...

Embodiment 2

[0042] like Figure 2~3 Shown is a schematic diagram of the inner superconducting layer and the outer superconducting layer of the superconducting composite conductor provided by the present invention.

[0043] The superconducting composite conductor includes an inner superconducting layer and an outer superconducting layer; the inner superconducting layer includes an inner superconducting layer unit and a filling factor arranged in the metal skeleton; the outer superconducting layer unit includes an outer superconducting layer wound on the metal skeleton The insulating layer outside the conducting unit and the outer superconducting unit.

[0044] like figure 2 Shown is a schematic diagram of the inner superconducting layer of the superconducting composite conductor provided by the present invention. The inner superconducting layer unit is a parallel structure of multiple high-temperature superconducting strips twisted along the length direction according to a specific pitch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com