Preparation method of high-temperature superconducting line

A technology of high-temperature superconducting and high-temperature superconducting strips, applied in the field of preparation of high-temperature superconducting wires, can solve the problems of low physical strength and unfavorable large-scale application, reduce critical current attenuation and AC loss, reduce external magnetic field, and not easily damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

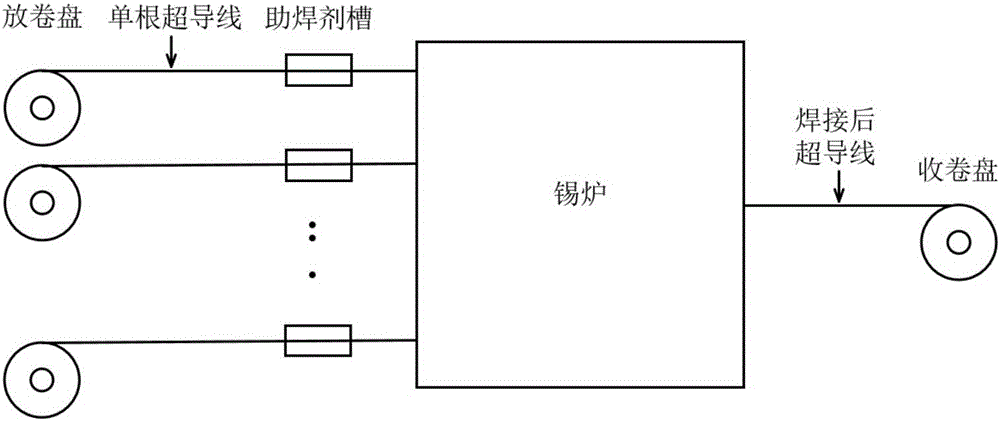

[0038] The preparation method of the high temperature superconducting wire described in the following examples, its technological process is as follows figure 1 As shown, a high temperature superconducting wire is obtained by stacking and welding a plurality of strips together by means of hot dip plating.

[0039] The preparation method specifically comprises the following steps:

[0040] Step 1. Fix each strip on the pay-off device, and locate the center line of the strip;

[0041] Step 2, adopt the method of reeling and unwinding the strip, and transport each strip into the tin furnace respectively;

[0042] Step 3: All strips are positioned in the tin furnace by rollers, welded and combined into one, and then released from the furnace to obtain the high-temperature superconducting wire.

[0043] The tape is a second-generation high-temperature superconducting tape with narrow filamentation.

[0044] The width of the strip is at least one of 1 mm or 2 mm.

[0045] The cr...

Embodiment 1

[0053] The present embodiment provides a method for preparing a square high-temperature superconducting wire, and the specific steps are as follows:

[0054] 1) Fix 6-8 narrow filament high-temperature superconducting tapes with a width of 1mm on the pay-off device, position the center line of the tape, and use the method of reeling and unwinding the tape. The deceleration motor plus the potentiometer controls each unwinding shaft by frequency conversion respectively. Use PP corrosion-resistant material as dip flux tank, each strip is independent;

[0055] 2) For the tin-coated part of the strip, the strips are separated before entering the tin furnace, positioned in the tin furnace by rollers and coated with tin to combine into one. The tin furnace is made of titanium metal. The temperature in the tin furnace is controlled by a temperature controller to detect the actual temperature. The temperature is controlled to carry out tin coating without destroying the superconduct...

Embodiment 2

[0059] The present embodiment provides a preparation method of a circular high-temperature superconducting wire, and the specific steps are as follows:

[0060] 1) 2 pieces of 1mm wide and 4 pieces of narrow filament high-temperature superconducting tapes with a width of 2mm are respectively fixed on the pay-off device, the center line of the tape is positioned, and the method of reeling and unwinding the tape is adopted. , and each unwinding reel is controlled by frequency conversion of multiple deceleration motors plus potentiometers. Use PP corrosion-resistant material as dip flux tank, each strip is independent.

[0061] 2) For the tin-coated part of the strip, the strips are separated before entering the tin furnace, positioned in the tin furnace by rollers and coated with tin to combine into one. The tin furnace is made of titanium metal. The temperature in the tin furnace is controlled by a temperature controller to detect the actual temperature. The temperature is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com