Planar transformer

A planar transformer, part of the technology, applied in the field of transformers, can solve the problem of inability to adjust leakage inductance and AC resistance, and achieve the effect of changing coupling performance and AC loss, good coupling and good heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

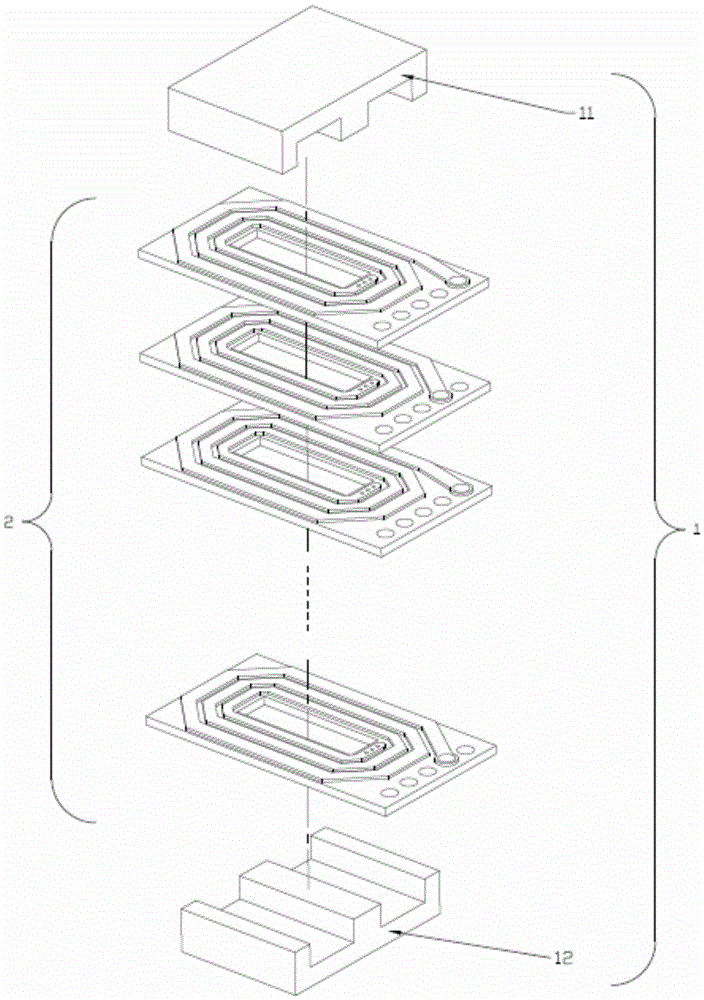

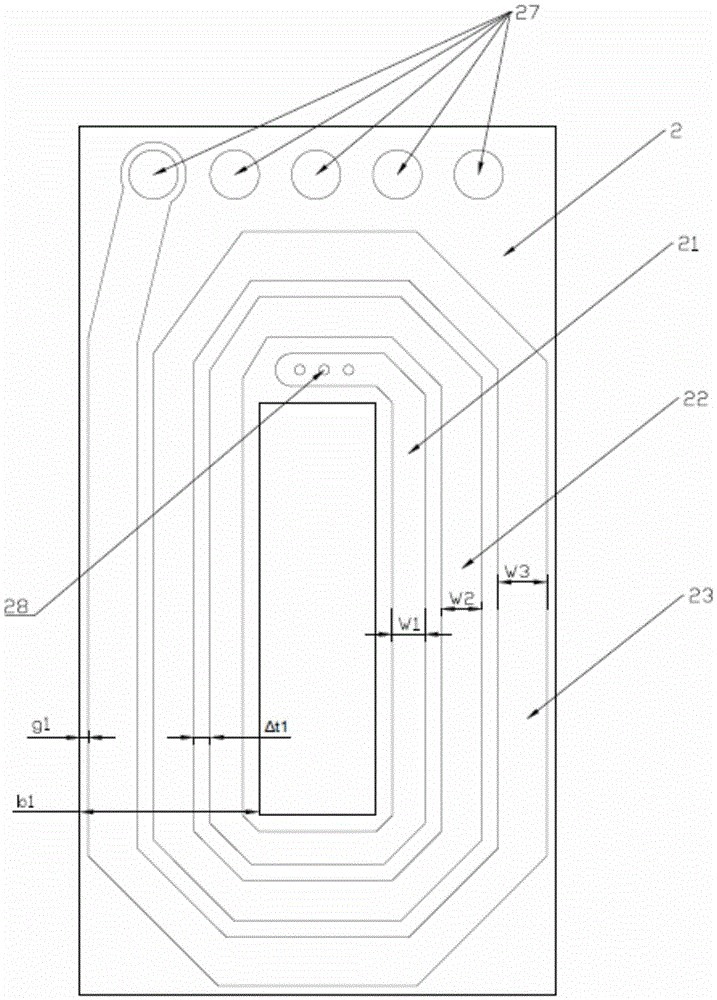

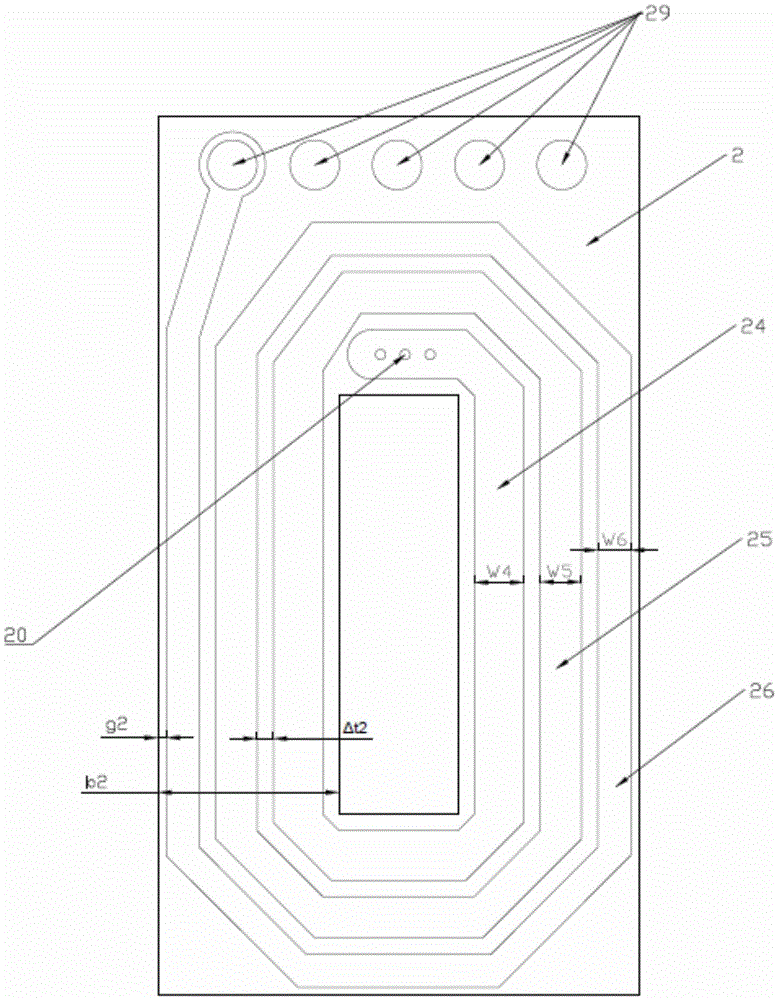

[0020] Such as figure 1 As shown, the planar transformer of this embodiment includes an upper magnetic core, a lower magnetic core, and a multilayer printed circuit board 2 arranged between the upper and lower magnetic cores for providing windings for the planar transformer. The magnetic core 1 provided by this embodiment It includes an upper magnetic core 11 and a lower magnetic core 12 respectively above and below the multilayer printed circuit board 2 . The upper magnetic core 11 and the lower magnetic core 12 are a pair of EE type planar magnetic cores, and may also be other magnetic cores, such as EI magnetic cores, ER magnetic cores and the like. This embodiment takes one coil per layer and three turns of each coil as an example, such as figure 2 As shown, the printed wires 21, 22, 23 on each layer of the multilayer printed circuit board 2 provide a coil around the central part of the magnetic core 1. The coil is printed with copper foil wires, and the printed wires ar...

Embodiment 2

[0042] Such as Figure 4 As shown, in this example, the multilayer printed circuit board in Example 1 is replaced by a plurality of copper sheets, and the coil on each copper sheet is still printed as in Example 1, and the other copper conductors except the coil part are made of stamped or otherwise removed. When copper sheets are used to replace multilayer printed circuit boards, it is equivalent to retaining the copper foil lines on the multilayer printed circuit boards, removing the substrate, and improving the flow capacity. The plurality of copper sheets are connected through through holes 31 . An insulating material needs to be provided between adjacent copper sheets for insulation.

[0043] On the basis of Embodiment 1, copper sheet 3 can be used to replace part or all of the multilayer printed circuit board 2, and at the same time, there is a preset winding ratio between the primary winding and the secondary winding, and the copper sheet 3 and the printed circuit boa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com